Non-autoclaved high-strength alkali-activated aerated concrete and preparation method and application thereof

An air-entrained concrete and autoclaving-free technology, applied in the field of building materials, can solve the problems of high water absorption, large shrinkage, low energy utilization rate, etc., and achieve low drying shrinkage and water absorption, energy saving and consumption reduction advantages, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

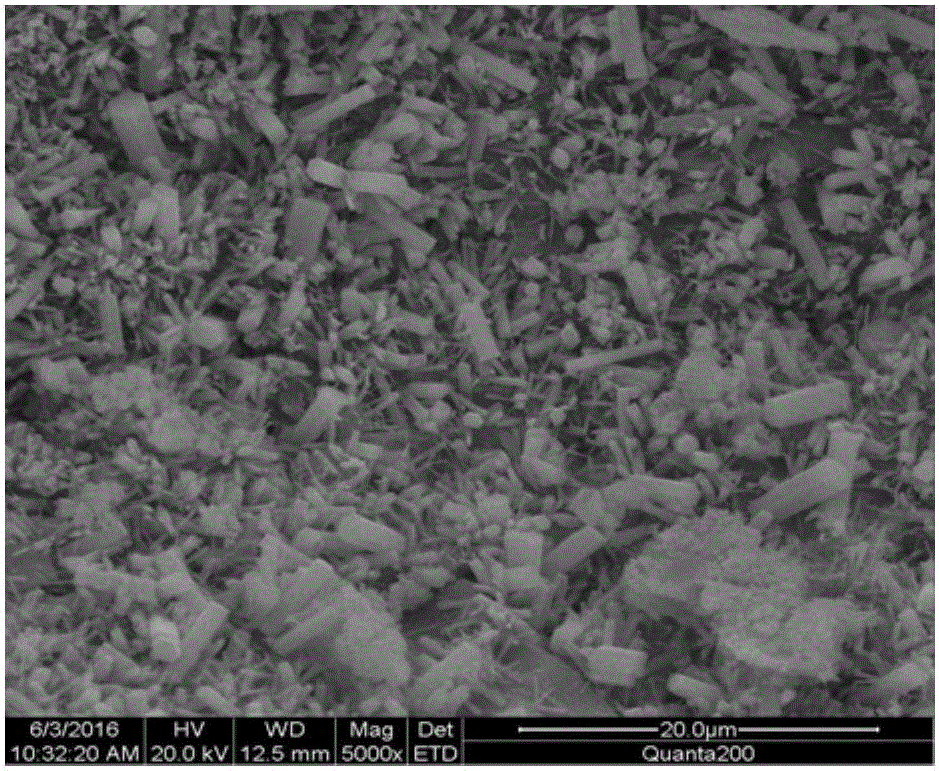

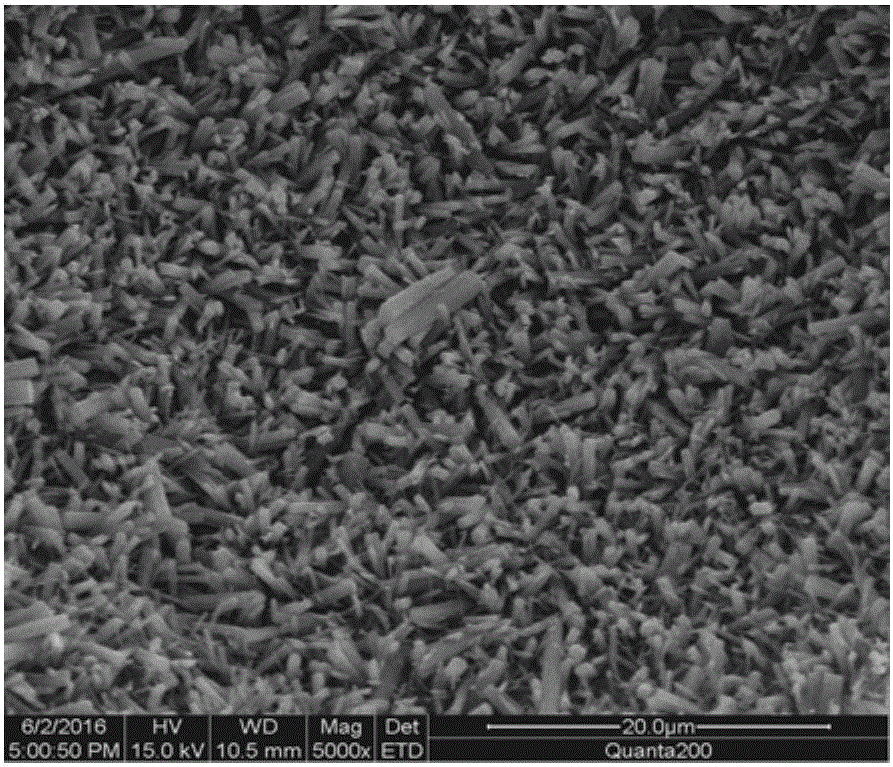

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of Autoclaved High-strength Alkali Excited Air-Entrained Concrete

[0028] 1) Weigh 200 parts of construction gypsum, 200 parts of high-alumina cement, 320 parts of mineral powder and 80 parts of nickel slag powder and mix them evenly, then pour them into a stirring pot to obtain the mixture;

[0029] 2) Weigh 8 parts of water reducing agent and 6.4 parts of sodium hydroxide into 223.2 parts of water, and stir slowly to fully dissolve the sodium hydroxide to obtain a solution;

[0030] 3) Slowly pour the solution prepared in step 2) into the mixture prepared in step 1), and stir slowly, then stir quickly for 30 seconds and then stir slowly until a uniform slurry is formed in the stirring pot;

[0031] 4) Pour 28 parts of foaming agent into the slurry obtained in step 3) quickly, and after stirring for 6 seconds, discharge the material into a mold, and let it stand to generate gas;

[0032] 5) After 2 hours, cut off the part of the bread that is hi...

Embodiment 2

[0033] Example 2 Preparation of Autoclaved High Alkali Excited Air-Entrained Concrete

[0034] 1) Weigh 200 parts of construction gypsum, 280 parts of high alumina cement, 256 parts of mineral powder and 64 parts of nickel slag powder and mix them evenly, then pour them into a stirring pot to obtain the mixture;

[0035] 2) Weigh 8 parts of water reducer and 5.1 parts of sodium hydroxide into 223.2 parts of water, and stir slowly to fully dissolve the sodium hydroxide to obtain a solution;

[0036] 3) Slowly pour the solution prepared in step 2) into the mixture prepared in step 1), and stir slowly, then stir quickly for 50 seconds and then stir slowly until a uniform slurry is formed in the stirring pot;

[0037] 4) Pour 24 parts of foaming agent into the slurry obtained in step 3) quickly, and after stirring for 8 seconds, discharge the material into a mold, and let it stand to generate gas;

[0038] 5) After 2.5 hours, cut off the part of the bread that is higher than the ...

Embodiment 3

[0040] 1) Weigh 280 parts of construction gypsum, 200 parts of high alumina cement, 256 parts of mineral powder and 64 parts of nickel slag powder and mix them evenly, then pour them into a stirring pot to obtain the mixture;

[0041] 2) Weigh 6 parts of water reducer and 5.1 parts of sodium hydroxide into 223.2 parts of water, and stir slowly to fully dissolve the sodium hydroxide to obtain a solution;

[0042] 3) Slowly pour the solution prepared in step 2) into the mixture prepared in step 1), and stir slowly, then stir quickly for 40 seconds and then stir slowly until a uniform slurry is formed in the stirring pot;

[0043] 4) Pour 20 parts of foaming agent into the slurry obtained in step 3) quickly, and after stirring for 7 seconds, discharge the material into a mold, and let it stand to generate gas;

[0044] 5) After 2 hours, cut off the part of the bread that is higher than the mold, then let it stand for 1 day to demould, and put it in a standard curing room for curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com