Super-slowly coagulating water reducer of concrete and its prepn.

A water-reducing agent and super-retarding technology, applied in the textile industry wastewater treatment and other directions, can solve problems such as incompatibility, and achieve the effects of small dosage, good adaptability and high water-reducing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

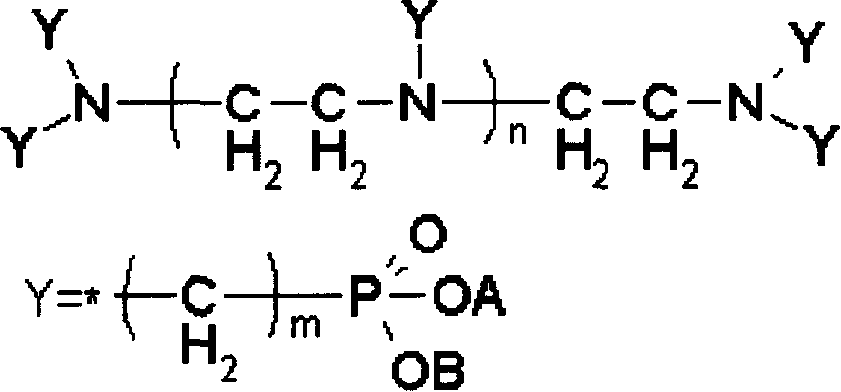

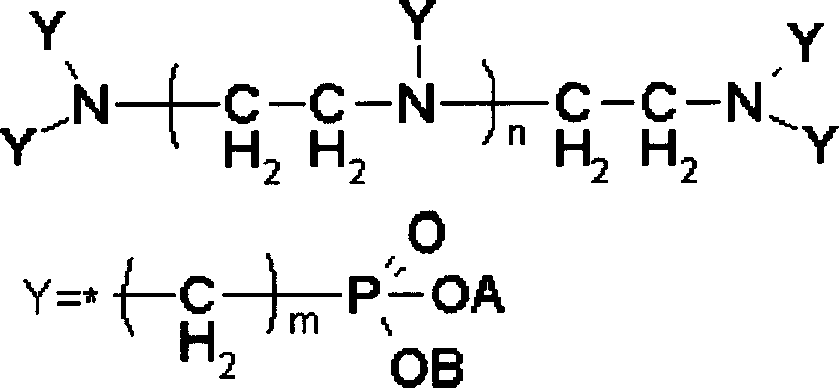

Method used

Image

Examples

Embodiment 1

[0035] Weigh 120g of modified lignosulfonate water reducer powder, dissolve it into a liquid water reducer with a concentration of 25%, and then add 2g of ethylene to the liquid modified lignosulfonate water reducer Stir diamine-tetramethylphosphonic acid and 40 g of phosphobutane tricarboxylic acid at a speed of 30 rpm, and stir for 20 minutes to obtain a super retarded superplasticizer. When used, it is prepared into an aqueous solution with a certain concentration in proportion.

Embodiment 2

[0037] Weigh 100g of naphthalenesulfonate water reducer powder, dissolve it into a liquid water reducer with a concentration of 25%, and then add 2g of ethylenediamine-tetramethyl to the liquid naphthalenesulfonate water reducer Phosphonic acid, 80 g of phosphobutane tricarboxylic acid, and 0.08 g of sodium lauryl sulfate were stirred at a speed of 20 rpm, and stirred for 40 minutes to obtain a super retarded superplasticizer. When used, it is prepared into an aqueous solution with a certain concentration in proportion.

Embodiment 3

[0039] Weigh 99.2g of polycarboxylic acid liquid superplasticizer with a concentration of 25%, mix in 48g of ethylenediamine-tetramethylphosphonic acid, 2g of phosphobutanetricarboxylic acid, and 0.4g of sodium lauryl sulfate for stirring , rotate at 30 rpm, and stir for 30 minutes to get super retarded superplasticizer. When used, it is prepared into an aqueous solution with a certain concentration in proportion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com