Polycarboxylic retarding high-performance water reducing agent for preparing concrete of middle and low strength grade

A high-efficiency water reducer and polycarboxylic acid-based technology, applied in the field of chemical building materials and construction, can solve the problems of high air content in fresh concrete, difficulty in controlling low dosage, and restrictions on popularization and application, and achieve low shrinkage ratio and high adaptability Good, the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

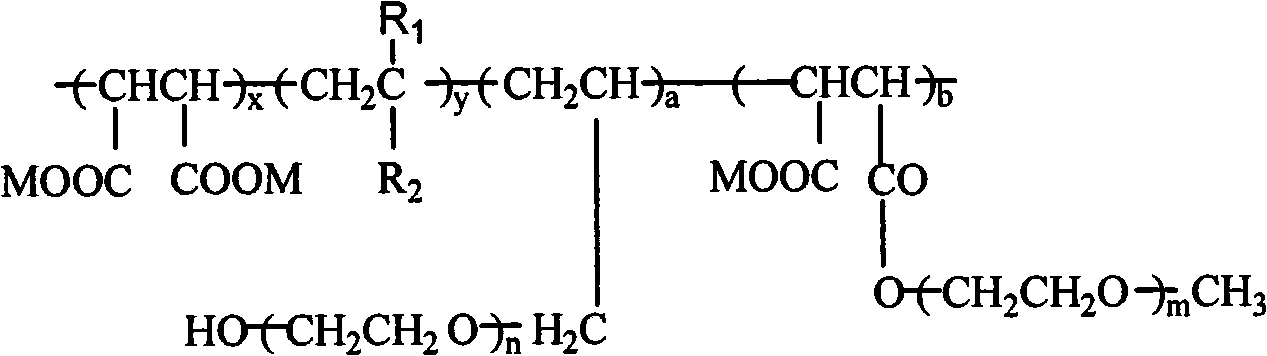

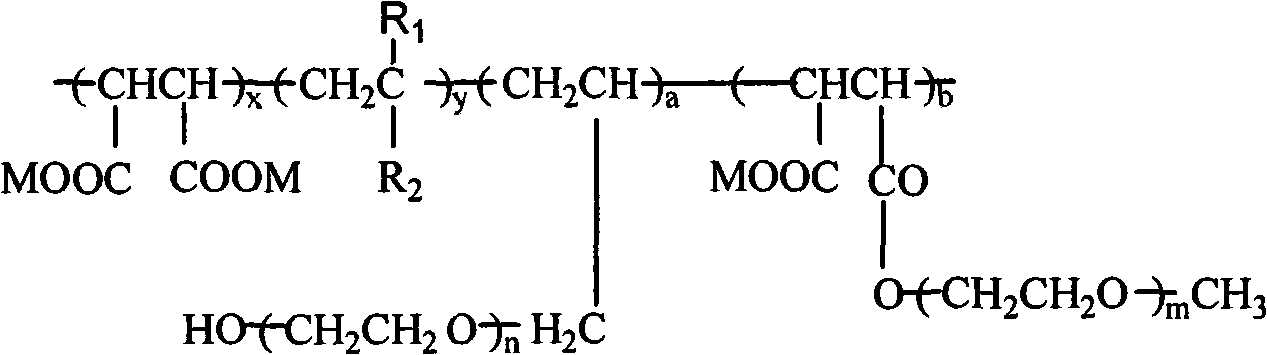

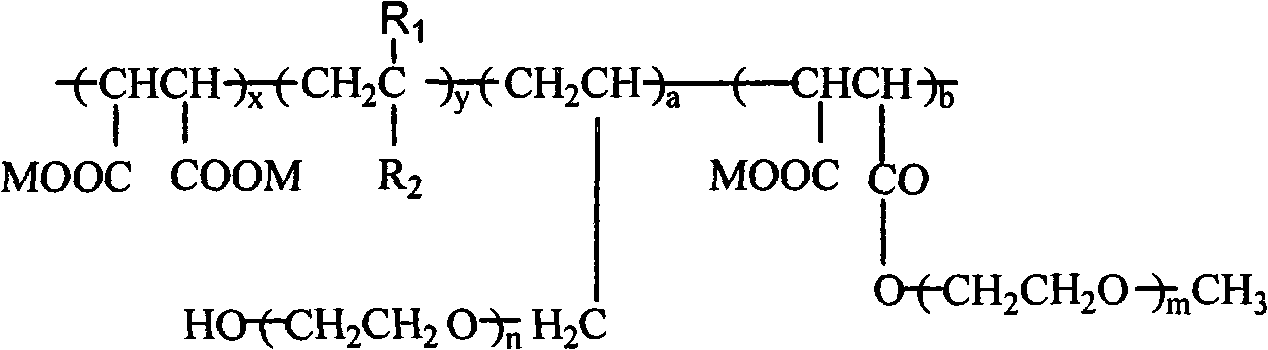

Method used

Image

Examples

Embodiment 1

[0031] Add 4415kg of water into the 5000L reactor, and then put in 500kg of low air-entraining polycarboxylate mother liquor, 85kg of retarder, 0.6kg of fatty alcohol polyoxyethylene ether sodium sulfate, 1.8kg of air-entraining agent, hydroxyethyl methylcellulose 1.0 kg of plain ether, 0.5 kg of hydroxypropyl distarch phosphate, and 3 kg of hexamethylenediamine tetramethylene phosphonic acid potassium salt were stirred until they were dissolved into a uniform solution (about 20 min), with a mass concentration of 7.01%.

Embodiment 2

[0033] Add 4300kg of water into the 5000L reactor, and then put in 600kg of low air-entraining polycarboxylate mother liquor, 100kg of retarder, 0.6kg of α-alkenyl sulfonate (AOS), 1.6kg of air-entraining agent, carboxymethyl fiber 0.8 kg of plain sodium, 0.4 kg of phosphorylated distarch phosphate, and 5 kg of potassium aminotrimethylene phosphonate were stirred until they were dissolved into a uniform solution (about 20 minutes), with a mass concentration of 8.38%.

Embodiment 3

[0035] Add 4150kg of water into the 5000L reactor, and then put in 750kg of low air-entraining polycarboxylate mother liquor, 100kg of retarder, 1kg of fatty alcohol polyoxyethylene ether sodium sulfate, 2kg of air-entraining agent, hydroxypropyl methyl cellulose ether 1.4kg, 0.7kg of phosphorylated distarch phosphate, 4kg of hexamethylenediamine tetramethylene phosphonic acid potassium salt, stir until they dissolve into a homogeneous solution (about 20min), with a mass concentration of 10.18%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com