Production process of movable false tooth

A manufacturing process and technology of removable dentures, applied in dentures and other directions, can solve problems such as affecting pronunciation, many parts, nausea, etc., and achieve the effect of reducing height, better wearing comfort, and reducing shrinkage ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings, wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower", "bottom" and "top" used in the following description refer to the Directions, the words "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

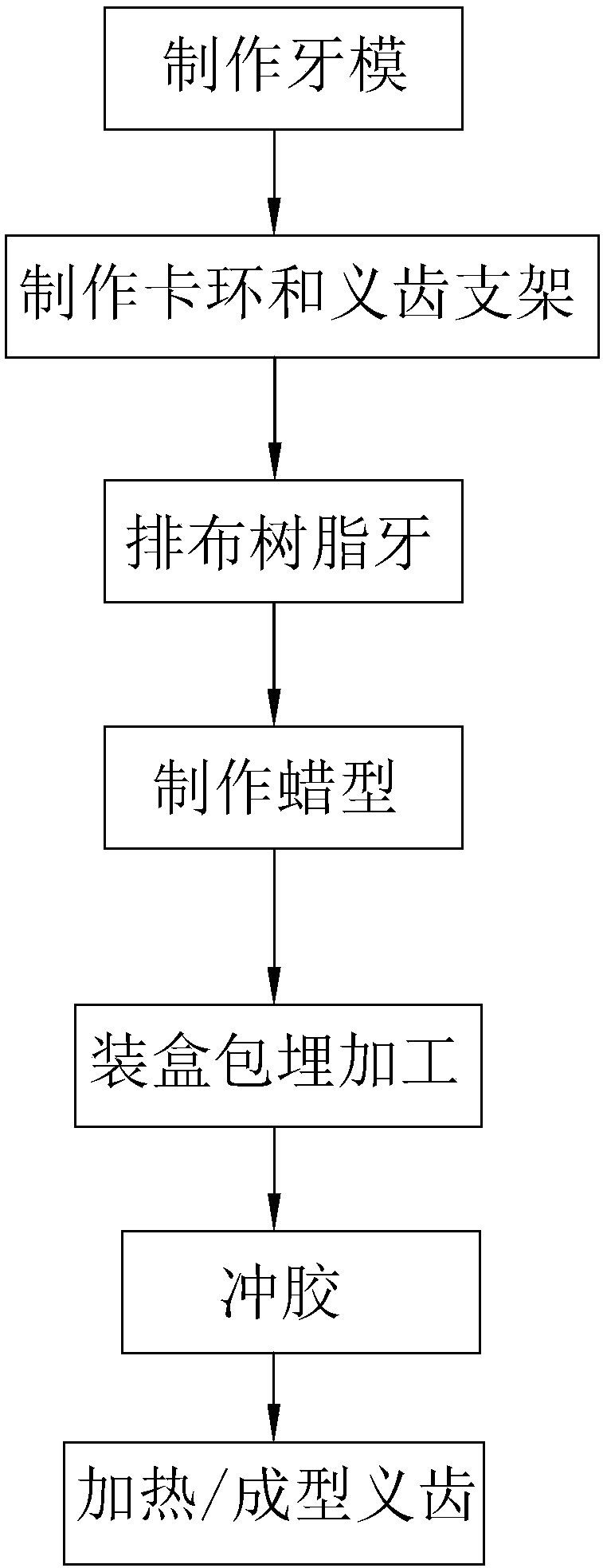

[0026] A removable denture manufacturing process such as figure 1 As shown, the steps include:

[0027] a. Design and make dental models;

[0028] b. Making denture brackets;

[0029] c. Arrange resin teeth;

[0030] d. Make wax type;

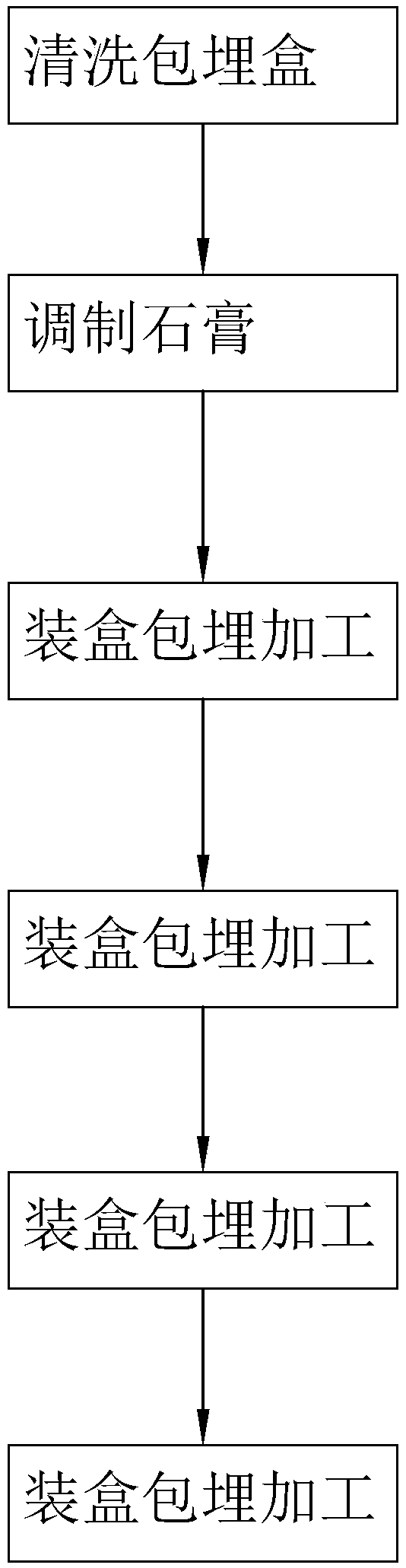

[0031] e. Cartoning and embedding processing;

[0032] f, punching glue;

[0033] g. Heating and forming dentures.

[0034] In step a, designing and making the dental model, setting is made according to the requirements, and the plaster working model is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com