Preparation method for admixture for plasterboard, admixture prepared thereby, and composition for forming plasterboard comprising same

A technology for gypsum boards and admixtures, applied in the field of preparation of gypsum board-forming compositions and admixtures for gypsum boards, capable of solving problems such as gel formation, achieving the effects of improving physical properties, shortening setting time, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] [Preparation method of admixture for gypsum board and admixture]

[0048] According to an embodiment of the present invention, there is provided a method for preparing an admixture for gypsum board, the admixture for gypsum board includes a sulfonated polystyrene (Sulfonated Polystyrene, SPS) compound represented by Chemical Formula 1, the sulfonated Polystyrene compounds are made by sulfonating polystyrene with sulfuric acid.

[0049] Chemical formula 1:

[0050]

[0051] Among them, R 1 and R 2 selected from hydrogen, heavy hydrogen, -F, -Cl, -Br, -I, hydroxyl, nitro, C 1 ~C 20 Alkyl, C 2 ~C 20 Alkenyl, C 2 ~C 20 Alkynyl, C 1 ~C 20 Alkoxy, C 3 ~C 10 Cycloalkyl, C 6 ~C 20 Aryl, C 1 ~C 20 Heteroaryl, monovalent non-aromatic fused polycyclic groups and monovalent non-aromatic fused heteropolycyclic groups,

[0052] a 1 is an integer selected from 1 to 5,

[0053] a 2 is an integer selected from 1 to 4,

[0054] m + for H + , Li + 、Na + 、K + o...

preparation example

[0133] Preparation example: preparation of SPS compounds

[0134] 1) Preparation of acetyl sulfate solution

[0135] Under the condition of inert nitrogen, cool the acetic anhydride to 0°C, and add 95-97% sulfuric acid, and then stir at room temperature until it becomes a transparent solution.

[0136] 2) Sulfonation

[0137] In the flask, polystyrene (Polystyrene) was dissolved in an organic solvent, and thereafter, the flask was purged with nitrogen gas for 30 minutes while being heated to 40°C. Then, after throwing in the said acetyl sulfate solution using the funnel, it stirred at 40 degreeC for 2 hours. Thereafter, when the solution was transparent yellow, 2-propanol was added, and after 30 minutes, it was cooled at room temperature to complete the reaction, thereby obtaining a polymerized sulfonated polystyrene compound. The resulting compound was isolated by washing in distilled water as needed.

[0138] 3) SPS compounds

[0139] The admixture was prepared by usi...

experiment example 1

[0140] Experimental example 1: IR measurement method (whether a sulfonic group is synthesized)

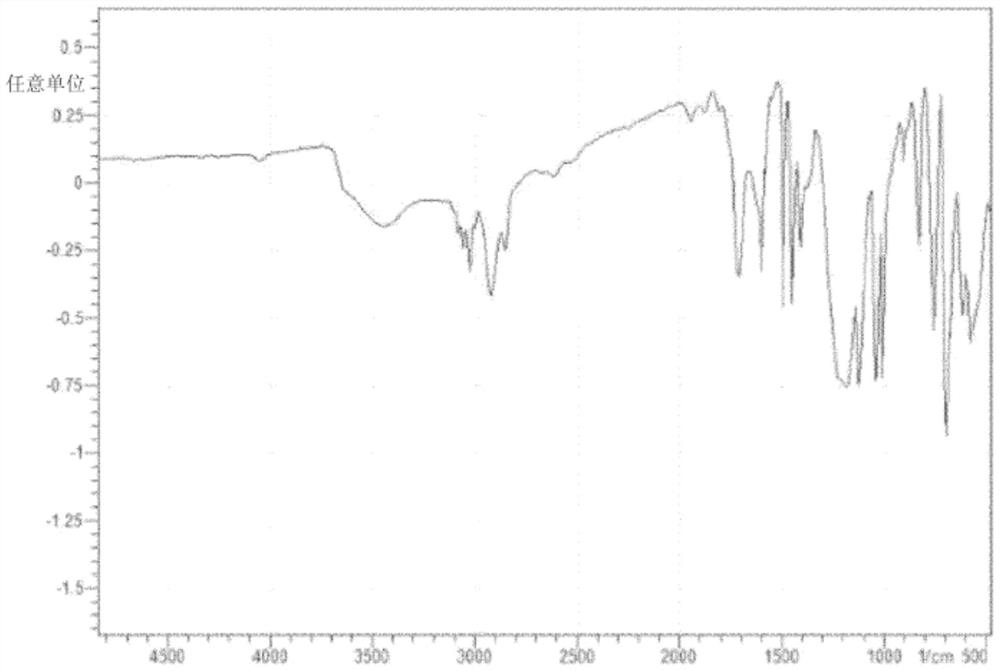

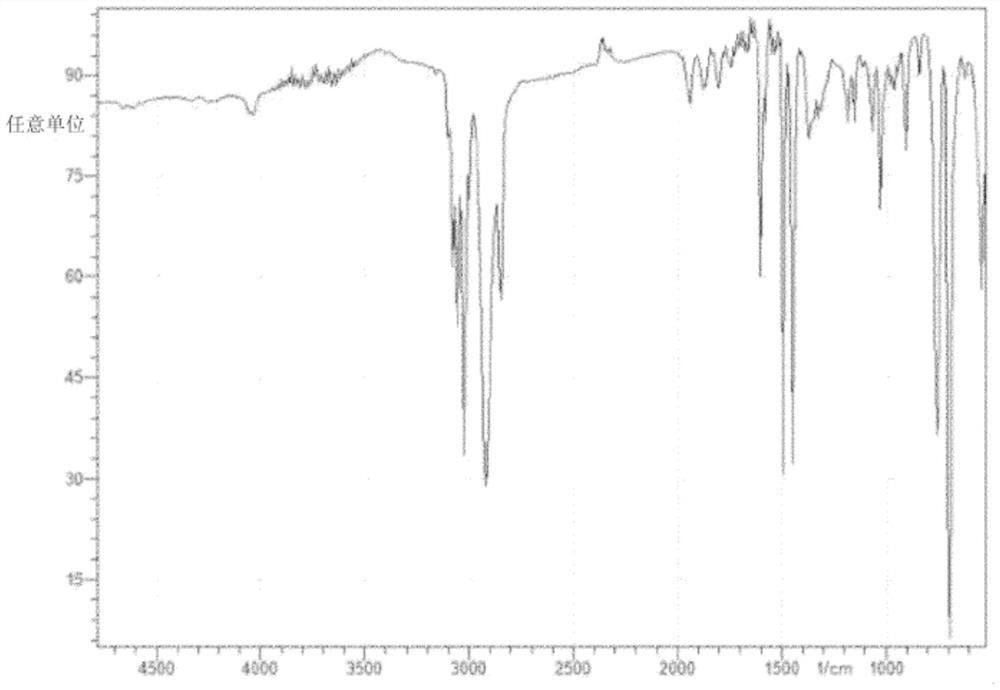

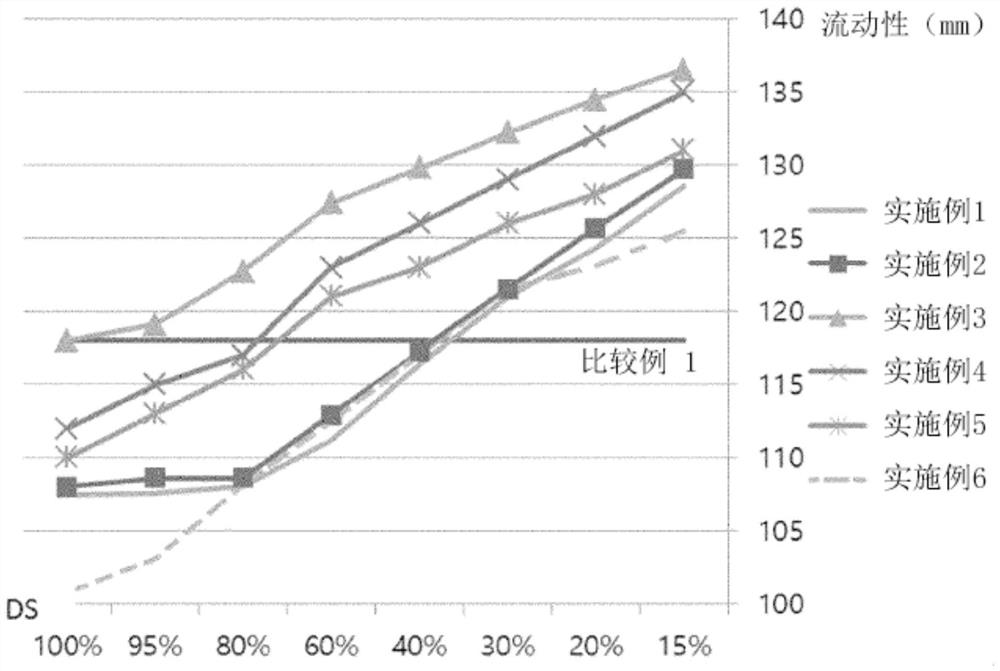

[0141] Whether a sulfonic group (sulfonic group) was synthesized on polystyrene in the sulfonated polystyrene (Sulfonated Polystyrene, SPS)-based compound prepared in 2) of the preparation example was analyzed using FT-IR measurement. show the result in figure 1 middle. In addition, at this time, the DS value was 35%. The FT-IR value of polystyrene without sulfonation reaction is shown in figure 2 in for comparison.

[0142] In addition, the degree of sulfonation (DS) of the sulfonated polystyrene compound can be estimated from the amount of the acetylsulfate solution injected. A more accurate measurement method can be through nuclear magnetic resonance (Nuclear magnetic resonance, NMR) spectroscopy (spectroscopy) and matrix-assisted laser desorption ionization time-of-flight mass spectrometry (Matrix-assisted laser desorption ionization time-of-flight mass spectrometry, MAL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com