Single-component oil-soluble polyurethane grouting material, and raw materials and preparation method thereof

A grouting material and oil-soluble technology, applied in the field of single-component oil-soluble polyurethane grouting material and its raw materials and preparation, can solve the problems of increased labor safety risks on construction sites, inability to meet the requirements of plugging and water-stopping, and deteriorating the environmental performance of products. , to achieve good elasticity and wet base bonding strength, high environmental protection, and the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

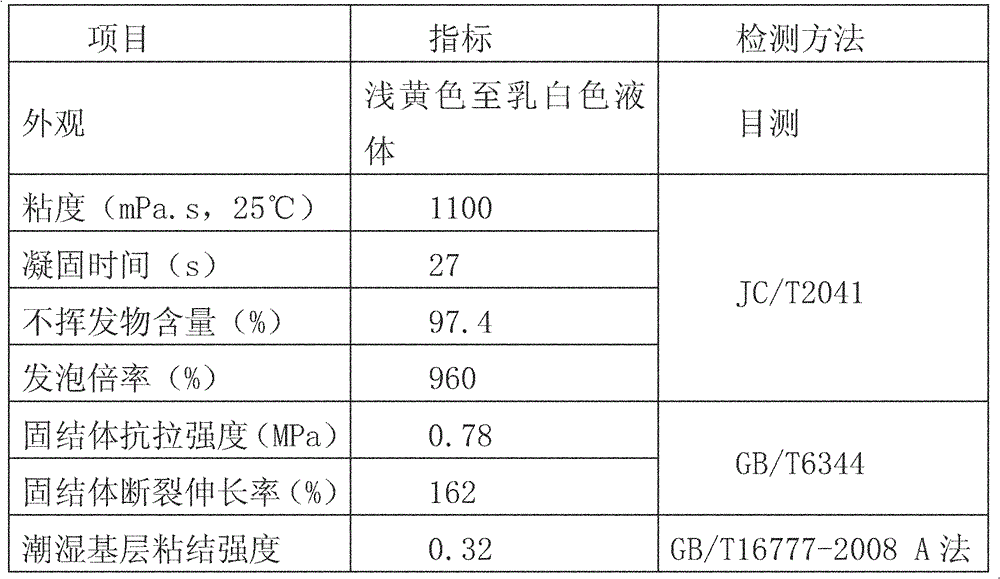

Embodiment 1

[0043] The raw material of one-component oil-soluble polyurethane grouting material is composed of the following components:

[0044] Polyether DL-1000 (Mn=1000, fn=2) 50 parts by weight

[0045] Polyether DL-2000 (Mn=2000, fn=2) 100 parts by weight

[0046]Polyether 330N (Mn=3000, fn=3) 50 parts by weight

[0047] Liquefied MDI (-NCO%≥30%) 114.7 parts by weight

[0048] 30 parts by weight of octyl phthalate

[0049] 5 parts by weight of polyalkylsiloxane

[0050] 6 parts by weight of N-methylmorpholine

[0051] The one-component oil-soluble polyurethane grouting material is prepared from the above raw materials.

[0052] The preparation method of the above-mentioned single-component oil-soluble polyurethane grouting material is as follows:

[0053] a. According to the above formula, add 200 parts by weight of polyether and 30 parts by weight of octyl phthalate into the reaction kettle with vacuum distillation device and stirrer, and dehydrate under the conditions of tem...

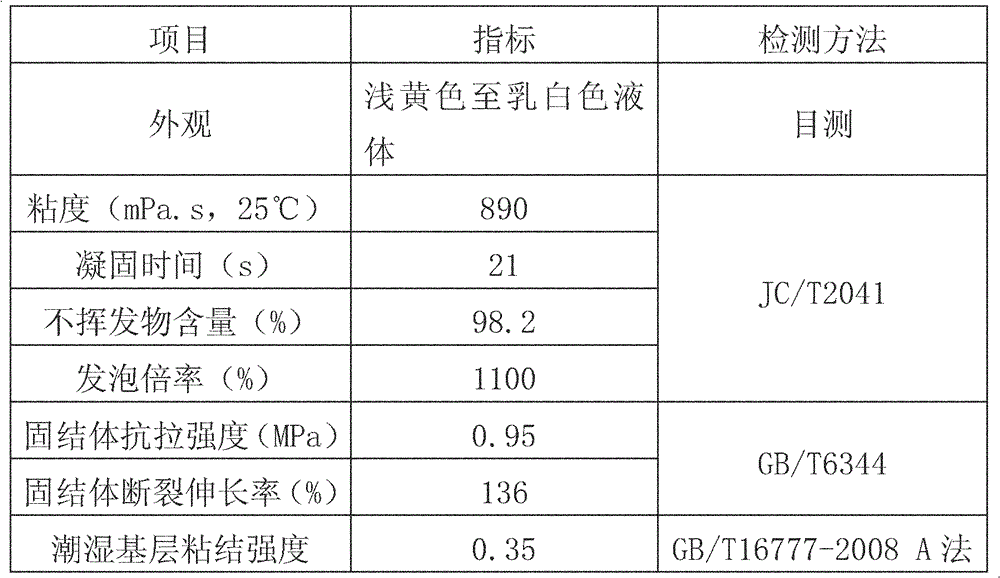

Embodiment 2

[0059] The raw material of one-component oil-soluble polyurethane grouting material is composed of the following components:

[0060] Polyether DL-400 (Mn=400, fn=2) 50 parts by weight

[0061] Polyether DL-1000 (Mn=1000, fn=2) 100 parts by weight

[0062] Polyether 330N (Mn=3000, fn=3) 50 parts by weight

[0063] Liquefied MDI (-NCO%≥30%) 159.4 parts by weight

[0064] 30 parts by weight of octyl phthalate

[0065] Polyalkylsiloxane 6.3 parts by weight

[0066] 7.2 parts by weight of stannous octoate

[0067] The one-component oil-soluble polyurethane grouting material is prepared from the above raw materials.

[0068] The preparation method of the above-mentioned single-component oil-soluble polyurethane grouting material is as follows:

[0069] a. According to the above formula, 200 parts by weight of polyether and 30 parts by weight of plasticizer (octyl phthalate) are added in the reaction kettle with vacuum decompression distillation device and stirrer, at a temper...

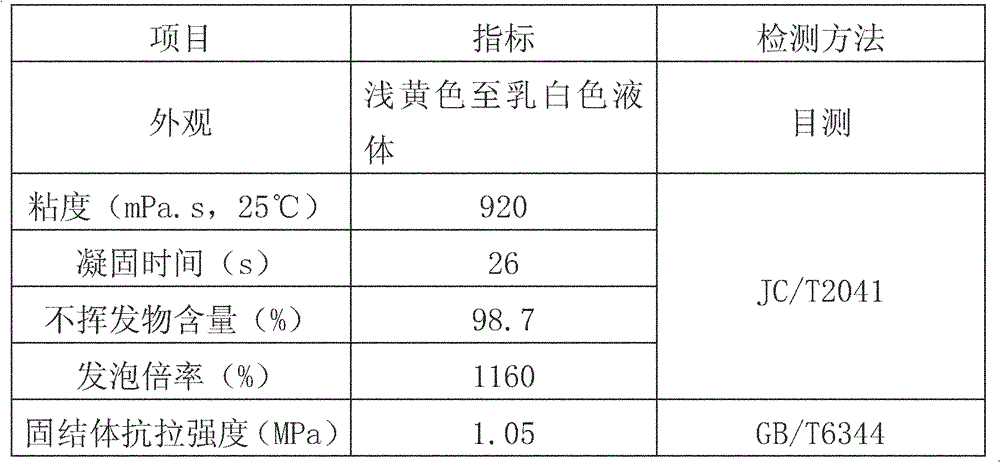

Embodiment 3

[0075] The raw material of one-component oil-soluble polyurethane grouting material is composed of the following components:

[0076] Polyether DL-400 (Mn=400, fn=2) 100 parts by weight

[0077] Polyether DL-2000 (Mn=2000, fn=2) 50 parts by weight

[0078] Polyether 330N (Mn=3000, fn=3) 50 parts by weight

[0079] PAPI (-NCO%≈32.5%) 141.5 parts by weight

[0080] 60 parts by weight of octyl phthalate

[0081] 4.5 parts by weight of polyalkylsiloxane

[0082] 6 parts by weight of stannous octoate

[0083] The one-component oil-soluble polyurethane grouting material is prepared from the above raw materials.

[0084] The preparation method of the above-mentioned single-component oil-soluble polyurethane grouting material is as follows:

[0085] a. According to the above formula, add 200 parts by weight of polyether and 60 parts by weight of octyl phthalate into a reaction kettle with a vacuum distillation device and agitator, and dehydrate at a temperature of 100 °C and a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com