High efficiency concrete retarding water reducer

A slow-setting water-reducing agent and concrete technology, applied in the field of retarding water-reducing agents, can solve the problems of accelerating cement hydration speed, hindering normal cement hydration, shortening cement setting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

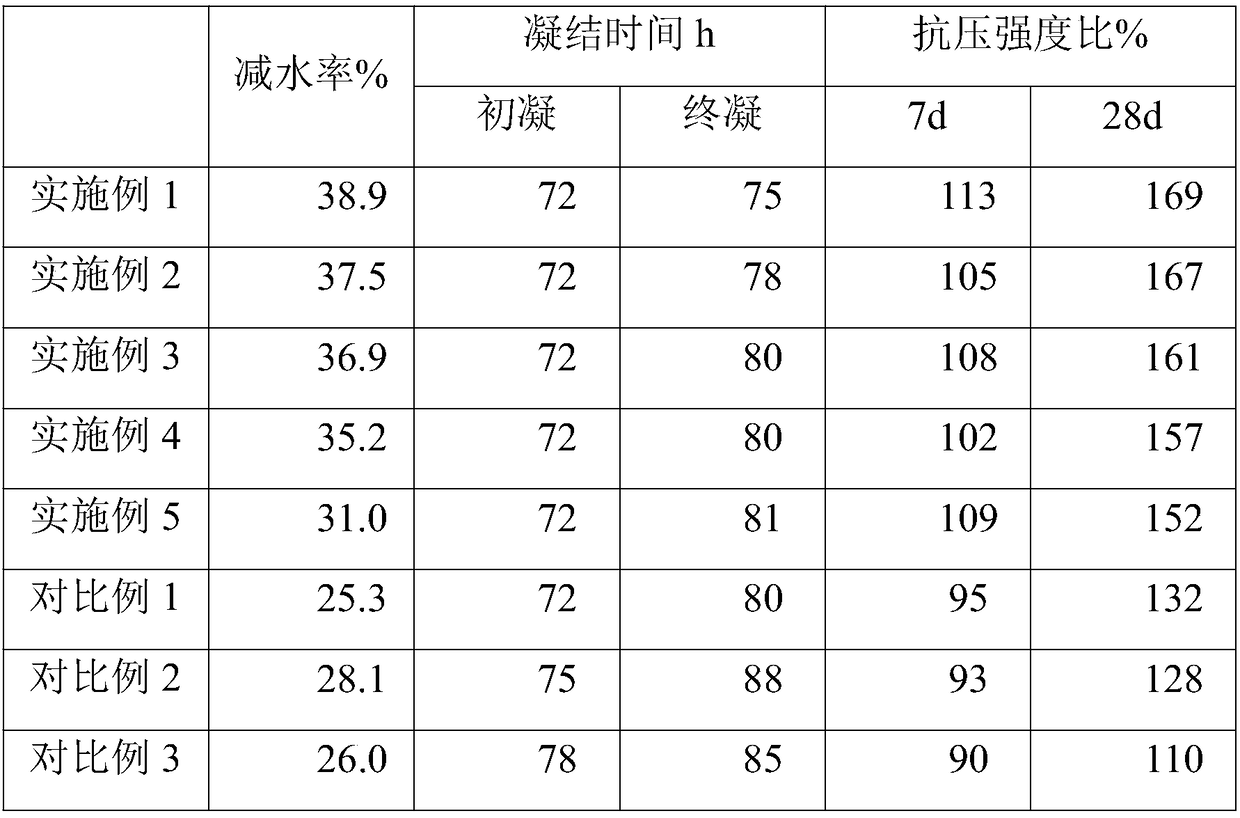

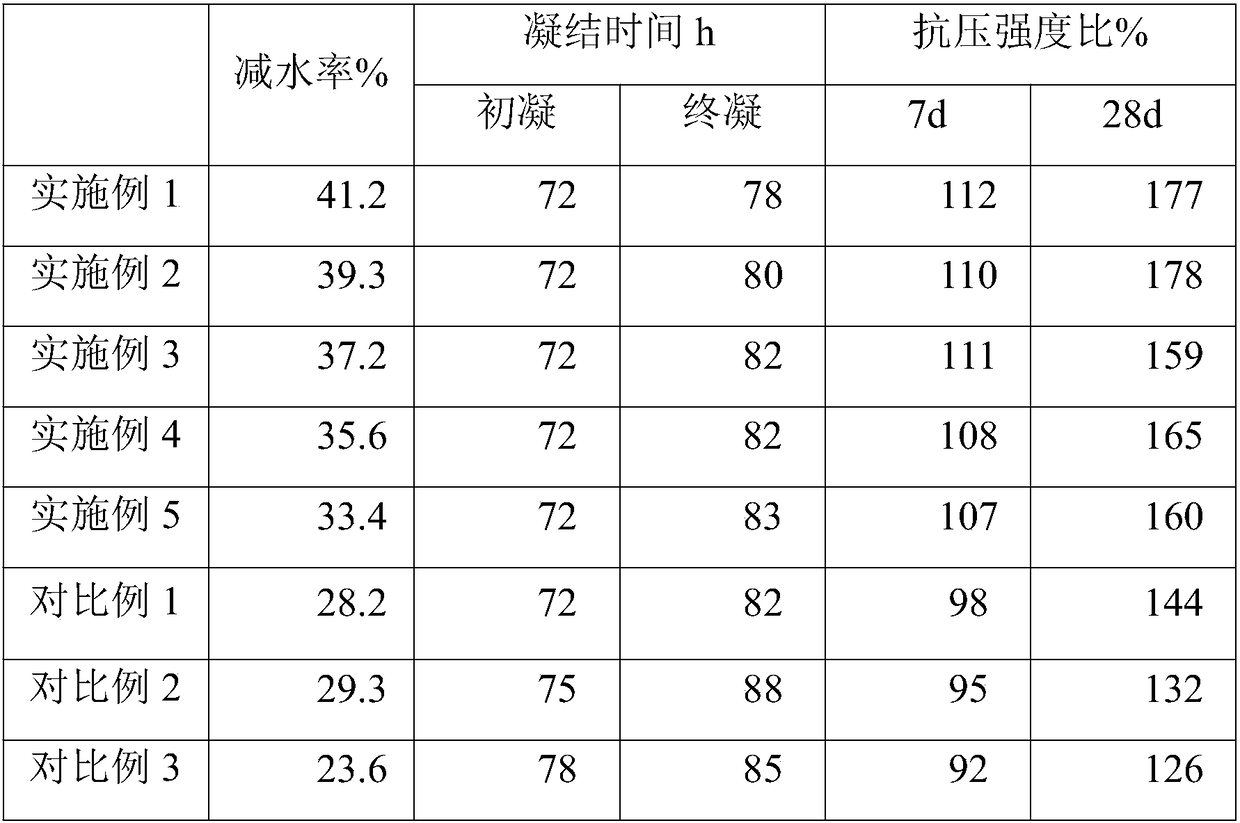

Examples

preparation example Construction

[0013] The present invention also provides a preparation method of the high-efficiency concrete retarding water reducer, comprising the following steps:

[0014] (1) Add sodium polyaspartate, p-aminobenzenesulfonic acid and polyethylene glycol monoethyl ether to polyaluminum chloride, then stir at 105-125°C for 0.5-1.5h, then place at 0-5°C Put it under seal and let it stand for 1-2h, and make fine powder through ultrafine pulverizer to obtain modified polyaluminum chloride;

[0015] (2) After mixing polycarboxylic acid mother liquor, sodium gluconate, maltodextrin polyacrylamide graft copolymer, chitin, ammonium citrate in the mixed solution of water and acetone, adjust the pH value of the mixed system to 6.5 ~7.5, then stirred at 80-100°C for 20-30min, then cooled naturally to room temperature, then added asbestos wool, modified polymeric alumina, anhydrous sodium sulfate and calcium chloride into the mixed system, and mixed evenly, that is Get retarded superplasticizer.

...

Embodiment 1

[0020] (1) Add 1.5g sodium polyaspartate, 3g p-aminobenzenesulfonic acid and 8g polyethylene glycol monoethyl ether to 4g polyaluminum chloride, then stir at 105-125°C for 0.5-1.5h, then set Seal and stand at 0-5°C for 1-2h, and make a fine powder through an ultrafine pulverizer to obtain modified polyaluminum chloride;

[0021] (2) 50g polyether polycarboxylic acid mother liquor (solid content is 55-75wt%, purchased from Ruitai Chemical Products Firm), 10g sodium gluconate, 5g maltodextrin polyacrylamide graft copolymer, 6g chitin After mixing 15g of ammonium citrate in a mixed solution of 45g of water and 5g of acetone, adjust the pH value of the mixed system to 6.5-7.5, then stir at 80-100°C for 20-30min, then cool naturally to room temperature, and then add Add 3g of asbestos wool, modified polyalumina, 5g of anhydrous sodium sulfate and 3g of calcium chloride into the mixing system, and mix evenly to obtain a retarded water reducer.

[0022] The preparation method of the...

Embodiment 2

[0024] (1) Add 0.5g sodium polyaspartate, 1g p-aminobenzenesulfonic acid and 6g polyethylene glycol monoethyl ether to 3g polyaluminum chloride, then stir at 105-125°C for 0.5-1.5h, then set Seal and stand at 0-5°C for 1-2h, and make a fine powder through an ultrafine pulverizer to obtain modified polyaluminum chloride;

[0025] (2) 42g polyester polycarboxylic acid mother liquor (solid content is 55-75wt%, purchased from Ruitai Chemical Products Firm), 8g sodium gluconate, 3g maltodextrin polyacrylamide graft copolymer, 5g chitin After mixing 12g of ammonium citrate in a mixed solution of 50g of water and 5g of acetone, adjust the pH value of the mixed system to 6.5-7.5, then stir at 80-100°C for 20-30min, then cool naturally to room temperature, and then add Add 2g of asbestos wool, modified polyalumina, 4g of anhydrous sodium sulfate and 4g of calcium chloride into the mixing system, and mix evenly to obtain a retarded water reducer.

[0026] The preparation method of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com