Process for treating high-COD (Chemical Oxygen Demand) and oil-content oil production wastewater

A technology for oil extraction wastewater and treatment process, applied in mining wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of slow sludge sedimentation, long reaction time, poor water quality, etc. The effect of sludge processing capacity, improving dewatering efficiency, and increasing processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

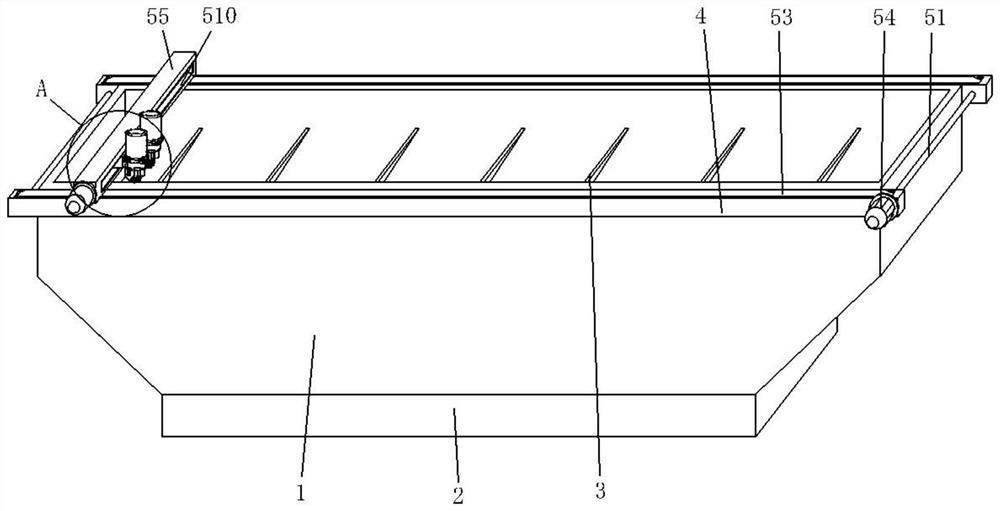

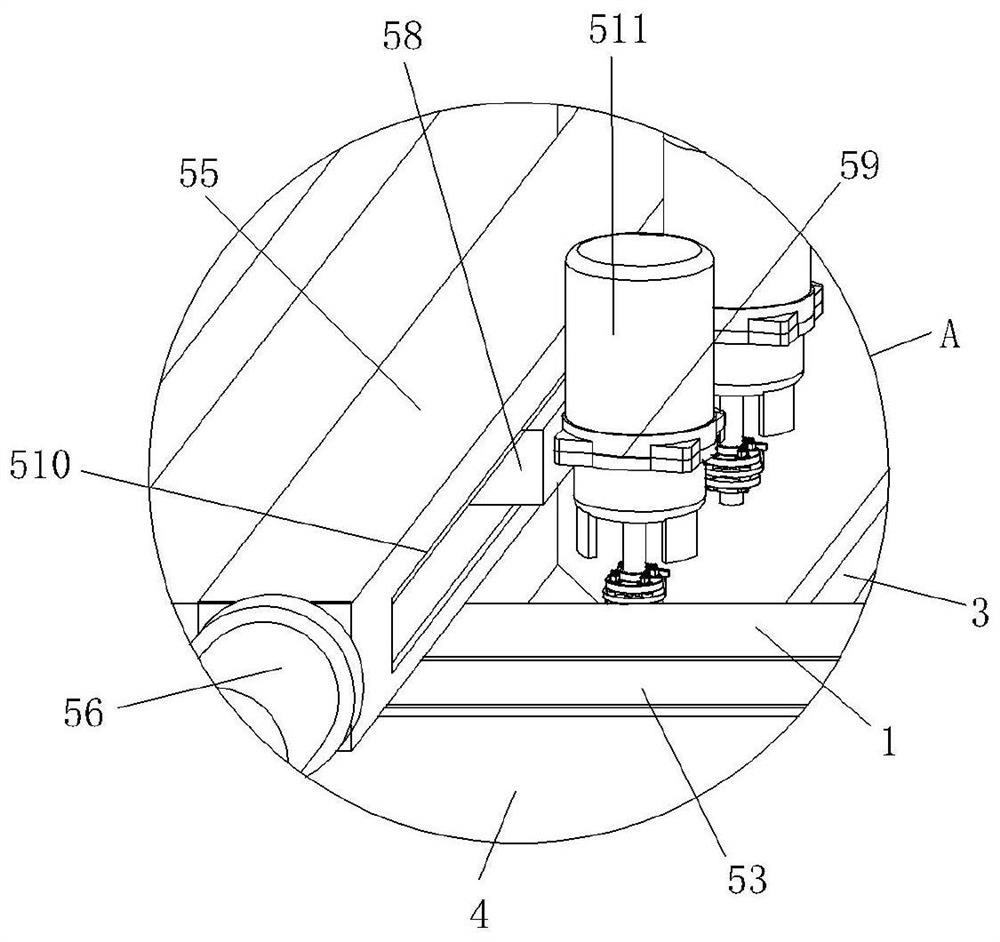

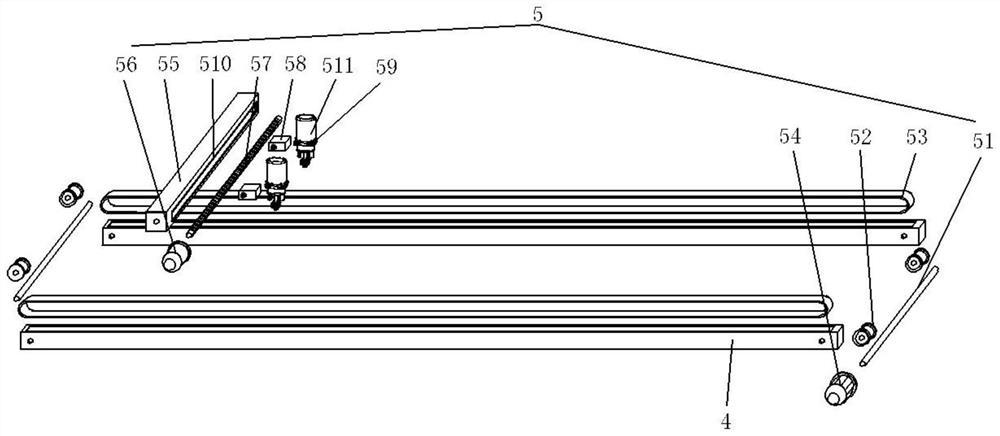

[0036] Embodiment 1, see Figure 1-4 , the present invention provides a technical solution: a treatment process that can be used for high COD and oil recovery wastewater, including: sedimentation tank 1, sludge collection seat 2, sedimentation plate 3, strip column 4 and dosing mechanism 5, sludge The collection seat 2 is fixedly arranged at the bottom of the sedimentation tank 1, and communicates with the inner cavity of the sedimentation tank 1. The inner cavity of the sedimentation tank 1 is provided with several sedimentation plates 3 in turn from left to right. All of them are fixedly arranged with bar columns 4 along the left and right directions, and the dosing mechanism 5 is arranged at the top of the bar columns 4 .

[0037] As a preferred solution, further, several settling plates 3 are arranged inclined from top to bottom to the left.

[0038]As a preferred solution, further, the dosing mechanism 5 includes: a rotating shaft 51, a pulley 52, a transmission belt 53 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com