Internal frame of plug

A technology of inner frame and plug, applied in the direction of contact parts, base/housing, riveted connection, etc., which can solve the problems of inability to produce concentrated strength anti-sudden pull and anti-swing tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

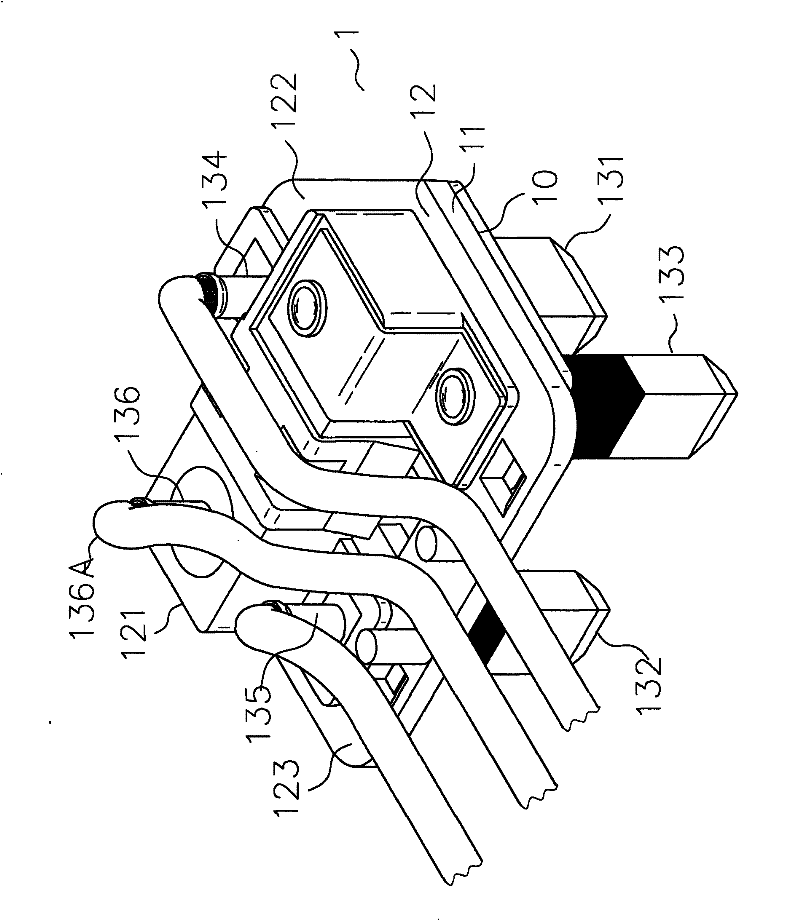

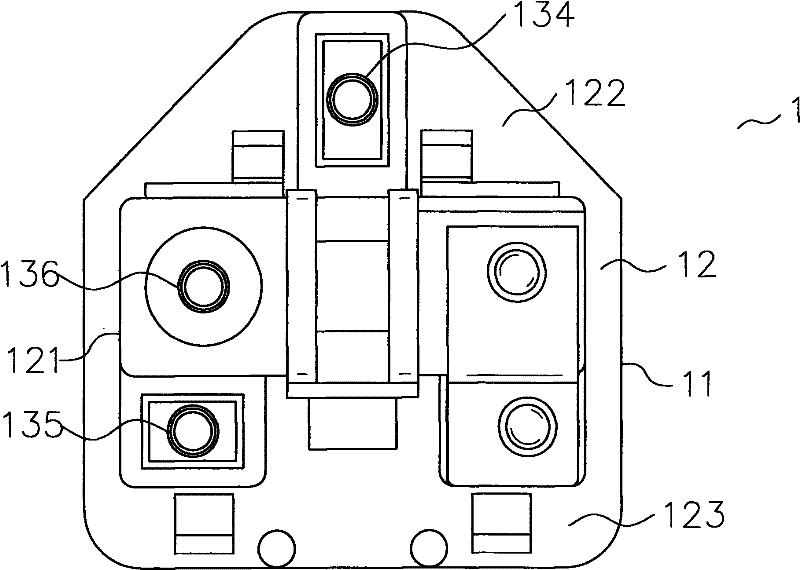

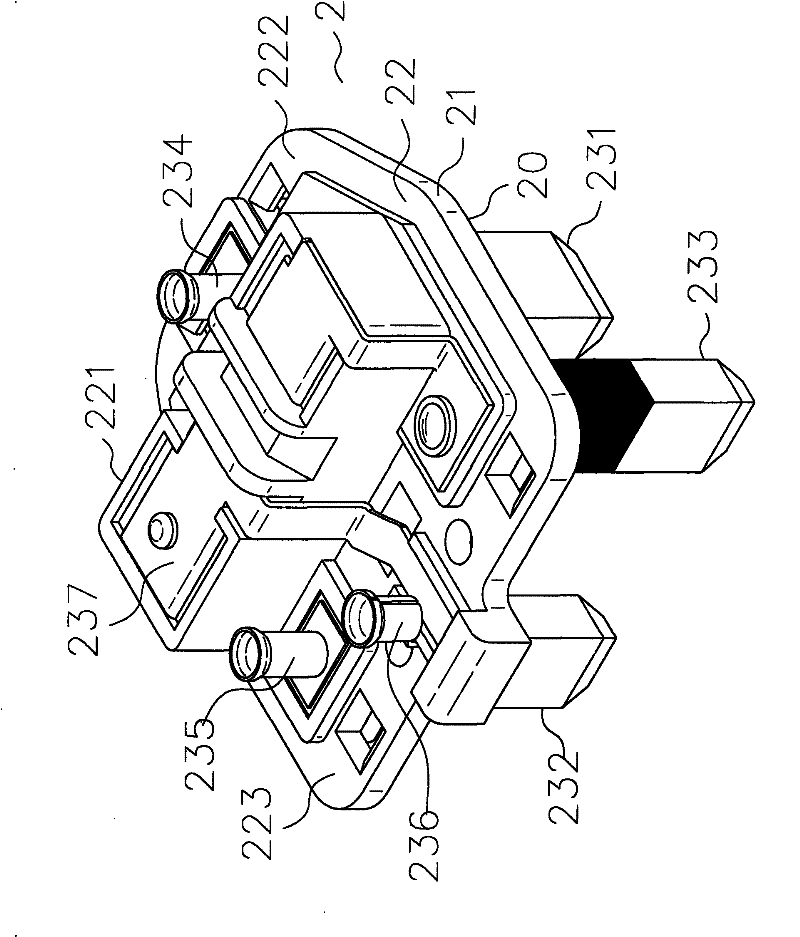

[0037] The structure, contents and embodiments of the present invention are described below with the aid of the accompanying drawings, so that the structure and advantages of the present invention can be further understood.

[0038] see Figure 5 As shown, the present invention relates to a plug inner frame that can gather riveted wire bundles in a short distance and can be placed with a fuse. The plug inner frame 3 of the present invention includes:

[0039] A frame body 31, the frame body 31 includes a first side 30, please cooperate Figure 10 As shown, the first side 30 is provided with a recessed groove 330 capable of accommodating a fuse. The recessed groove 330 is provided with two sections of fuse holders 339A, 339B. The recessed groove 330 is opposite so that the second side 32 forms a raised portion 321. Two sides of the protruding portion 321 are divided into a first relative concave surface 322 and a second relative concave surface 323 which are relatively low.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com