Fireproof door core board and production process thereof

A fire door core board and foaming agent technology, applied in the field of fire doors, can solve the problems of complex raw material composition, high cost, and hindered market application of the door core board, and achieve strong adjustability, easy regulation, and a wide range of additions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

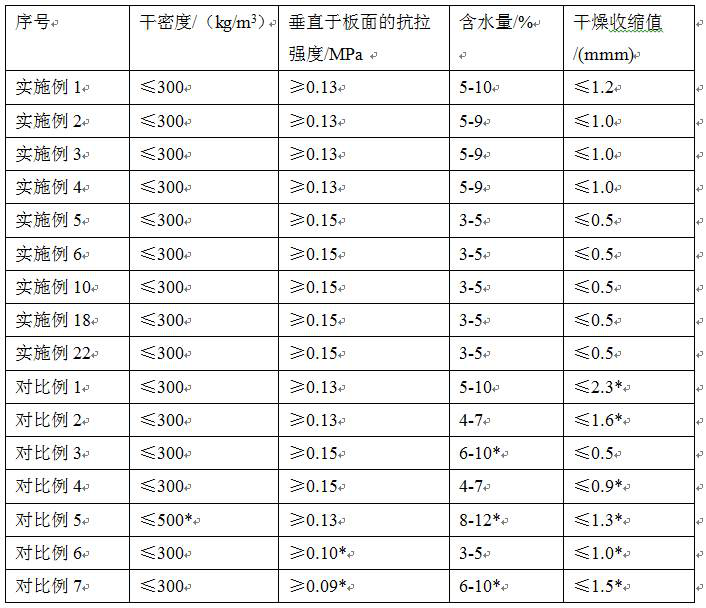

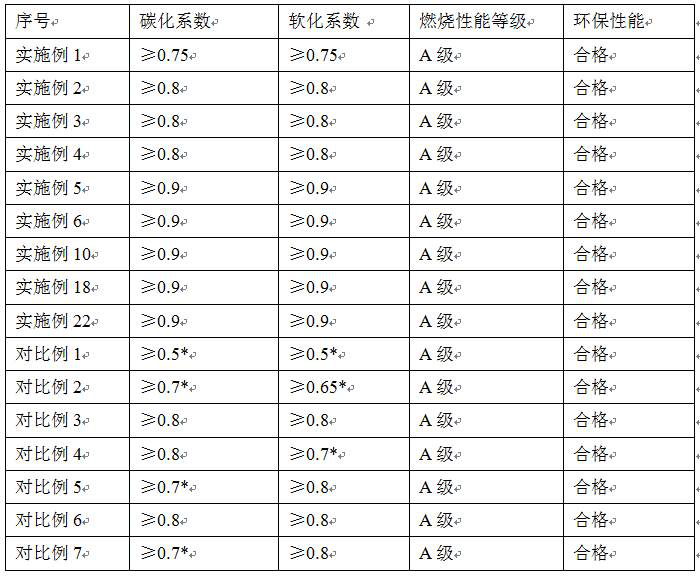

Examples

Embodiment 1

[0060] The fire door core board is made of the following raw materials in parts by weight: 80 parts of cement, 0.2 part of foaming agent, 0.1 part of polypropylene fiber, and 140 parts of water.

[0061] In this embodiment, the cement is slag cement, and the foaming agent is HTN type foaming agent.

Embodiment 2

[0063] The fire door core board is made of the following raw materials in parts by weight: 150 parts of cement, 3 parts of foaming agent, 0.5 part of polypropylene fiber, 143 parts of water, and 0.01 part of early strength superplasticizer.

[0064] In this embodiment, the cement is pozzolanic cement, the foaming agent is HTN foaming agent, and the early-strength water reducer is naphthalene-based high-efficiency water reducer FDN-A.

Embodiment 3

[0066] The fire door core board is made of the following raw materials in parts by weight: 200 parts of cement, 5 parts of foaming agent, 0.7 part of polypropylene fiber, 150 parts of water, and 0.3 part of early strength superplasticizer.

[0067] In this example, the cement is composite cement, the foaming agent is hydrogen peroxide and a foam stabilizer, the quality of the foam stabilizer is 1% of the hydrogen peroxide, and the early-strength water reducer is an early-strength polycarboxylate high-performance water reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com