Core-shell pure acrylic emulsion for exterior wall coating as well as preparation method and application thereof

A technology of pure acrylic emulsion and exterior wall coating, applied in the direction of coating, etc., can solve the problems of poor resistance to rain marks and poor water resistance, and achieve the effect of enhancing adhesion, improving water resistance, and improving the strength of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

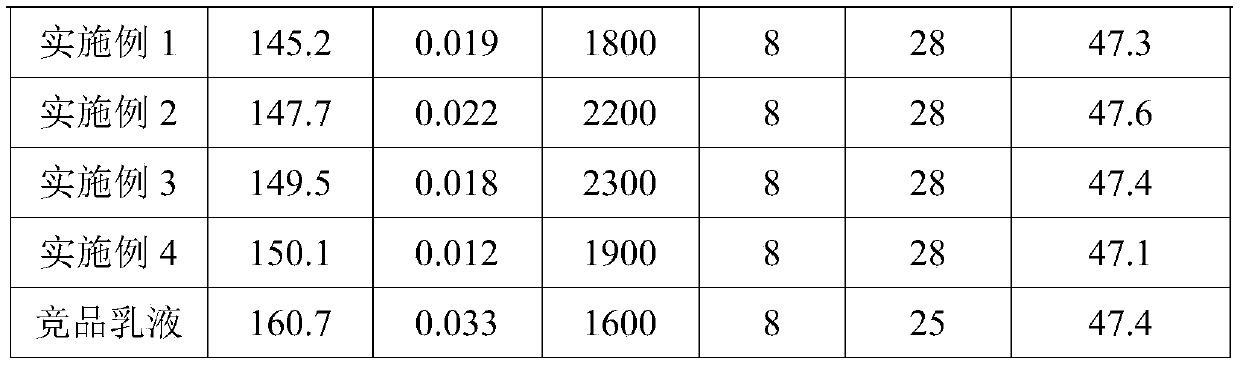

Embodiment 1

[0041] Core-shell pure acrylic emulsion for exterior wall coatings, in parts by mass, includes the following components:

[0042] Main monomer: 12 parts of butyl acrylate (with a core-shell ratio of 3:9), 18 parts of methyl methacrylate (with a core-shell ratio of 12:6), 5 parts of hydroxyethyl acrylate (with a core-shell ratio of 5:0), 4 parts of methacrylic acid (the core-shell ratio is 3:1);

[0043] Hydrophobic soft monomer: 5 parts of isodecyl acrylate;

[0044] Polar monomer: 0.2 parts of vinyltriethoxysilane;

[0045] Self-crosslinking monomer at room temperature: component A, 0.5 part of diacetone acrylamide and component B, 0.25 part of adipic acid dihydrazide;

[0046] Photoinitiated crosslinking agent: 0.5 parts of benzophenones;

[0047] Reactive emulsifier: 0.9 parts of unsaturated allyl alkyl ammonium sulfate;

[0048] Nonionic emulsifier: 0.03 part of isomerized C13 fatty alcohol;

[0049] Initiator: 0.06 parts of potassium persulfate;

[0050] pH neutrali...

Embodiment 2

[0055] Core-shell pure acrylic emulsion for exterior wall coatings, in parts by mass, includes the following components:

[0056] Soft monomer and hard monomer: 12 parts of butyl acrylate (with a core-shell ratio of 3:9), 18 parts of methyl methacrylate (with a core-shell ratio of 12:6), 5 parts of hydroxyethyl acrylate (with The core-shell ratio is 5:0), 4 parts of methacrylic acid (the core-shell ratio is 3:1);

[0057] Hydrophobic soft monomer: 5 parts of isodecyl methacrylate;

[0058] Polar monomer: 0.2 parts of vinyltriethoxysilane;

[0059] Self-crosslinking monomer at room temperature: component A, 0.5 part of diacetone acrylamide and component B, 0.25 part of adipic acid dihydrazide;

[0060] Photoinitiated crosslinking agent: 0.5 parts of benzophenones;

[0061] Reactive emulsifier: 0.9 parts of unsaturated allyl alkyl ammonium sulfate;

[0062] Nonionic emulsifier: 0.03 part of alkyl polyoxyethylene ether;

[0063] Initiator: 0.06 parts of potassium persulfate;...

Embodiment 3

[0069] Core-shell pure acrylic emulsion for exterior wall coatings, in parts by mass, includes the following components:

[0070] Soft monomer and hard monomer: 12 parts of butyl acrylate (with a core-shell ratio of 3:9), 18 parts of methyl methacrylate (with a core-shell ratio of 12:6), 5 parts of hydroxyethyl acrylate (with The core-shell ratio is 5:0), 4 parts of methacrylic acid (the core-shell ratio is 3:1);

[0071] Hydrophobic soft monomer: 5 parts of isodecyl methacrylate;

[0072] Polar monomer: 0.2 parts of vinyltriethoxysilane;

[0073] Self-crosslinking monomer at room temperature: component A, 0.5 part of diacetone acrylamide and component B, 0.25 part of adipic acid dihydrazide;

[0074] Photoinitiated crosslinking agent: 0.5 parts of benzophenones;

[0075] Reactive emulsifier: 1 part of methacrylate ether phosphate and 1.1 parts of allyl alkyl sulfosuccinic acid diester sodium;

[0076] Nonionic emulsifier: 0.03 part of isomerized C13 fatty alcohol;

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com