Method for manufacturing anode foil of alternating current motor capacitor

A manufacturing method and AC motor technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve problems such as poor hydration characteristics, large leakage current of forming foil, and large leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

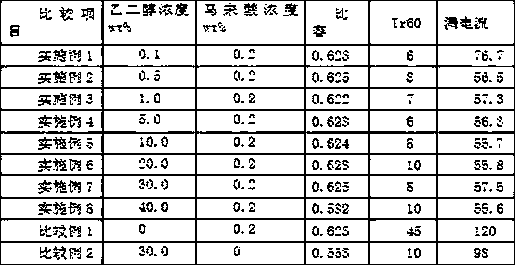

Examples

Embodiment 1

[0027] A method of manufacturing an anode foil for an AC motor capacitor:

[0028] Hydration treatment: Take a corroded foil with penetrating corrosion holes and an average pore diameter of 1.5 μm, and immerse it in an ethylene glycol solution with a concentration of 0.1wt% and a temperature of 90°C for 5 minutes;

[0029] Chemical conversion pretreatment: then the concentration is 0.2wt%, the temperature is 75 ℃ maleic acid solution treatment time is 2 minutes;

[0030] Five-stage chemical conversion treatment: take it out and place it in phosphate with a concentration of 0.1wt%, at 75°C and a current density of 20mA / cm 2 10 minutes under the condition of voltage of 100V;

[0031] Take it out and place it in phosphate with a concentration of 0.05wt% and a temperature of 75°C, with a current density of 20mA / cm 2 10 minutes under the condition of voltage of 200V;

[0032] Take it out and wash it with water for 2 minutes; then place it in a solution with a concentration of 5w...

Embodiment 2

[0038] A method of manufacturing an anode foil for an AC motor capacitor:

[0039] Take a corroded foil with penetrating corrosion holes and an average pore diameter of 1.8 μm, and immerse it in an ethylene glycol solution with a concentration of 0.5wt% and a temperature of 90°C for 5 minutes;

[0040] Then the concentration is 0.2wt%, and the temperature is 75 ℃ maleic acid solution treatment time is 2 minutes;

[0041] Take it out and place it in phosphate with a concentration of 0.1wt%, at 75°C, with a current density of 20mA / cm 2 10 minutes under the condition of voltage of 100V;

[0042] Take it out and place it in phosphate with a concentration of 0.05wt% and a temperature of 75°C, with a current density of 20mA / cm 2 10 minutes under the condition of voltage of 200V;

[0043] Take it out and wash it with water for 2 minutes; then place it in a solution with a concentration of 5wt% boric acid and 0.2wt% ammonium pentaborate at a temperature of 75°C and a current densit...

Embodiment 3

[0049] Under the production conditions according to Example 1, the concentration of the water and the ethylene glycol solution in the treatment step was controlled at 1.0 wt%.

[0050] The dielectric properties of the oxide film of the anode foil produced based on this embodiment are good, and the leakage current is 57.3 uA / 5cm 2 ; High hydration resistance, Tr60 is 7S; bending strength is 122 times. From the observation of SEM scanning electron microscope, there is almost no hydrated oxide film on the surface of the oxide film, which can meet the needs of frequent charging and discharging of the motor starting capacitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Leakage current | aaaaa | aaaaa |

| Leakage current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com