Compound demulsifying agent and method of use thereof

A composite demulsification and styrene technology, applied in chemical instruments and methods, dissolution, immiscible liquid separation, etc., can solve the problems of unsatisfactory demulsification effect of high asphaltene heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

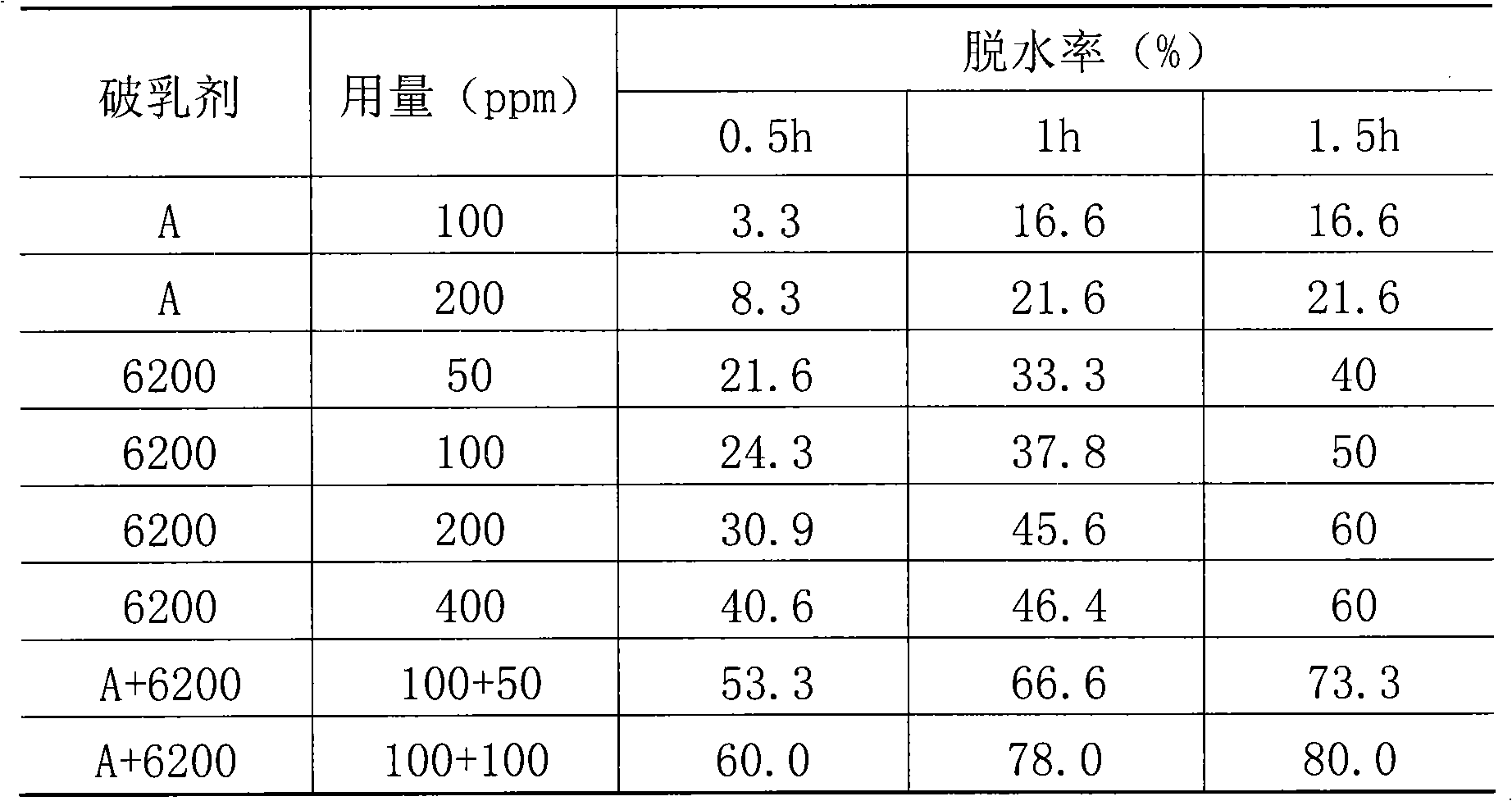

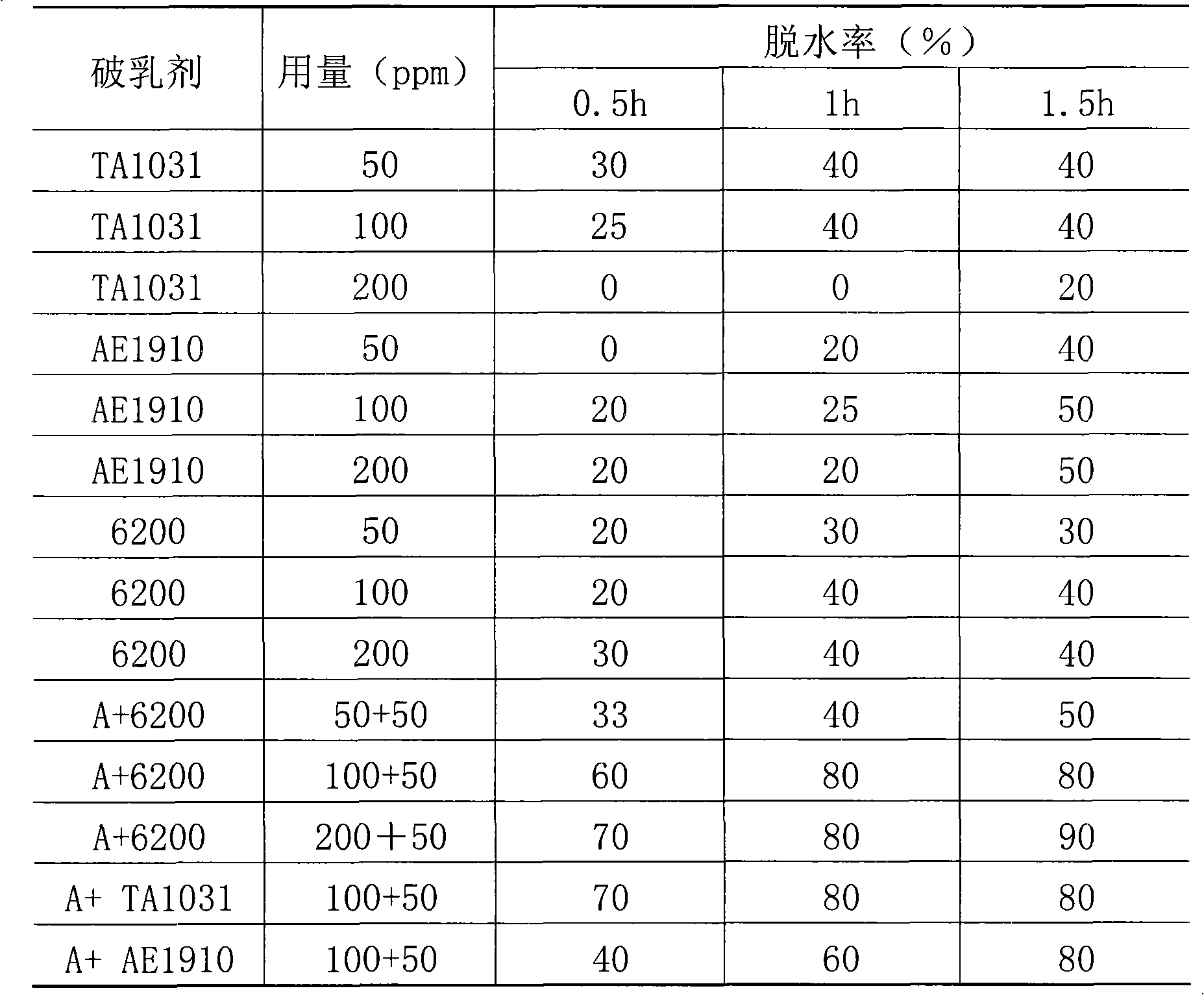

Examples

Embodiment 1

[0023] Add 9.8g of maleic anhydride and 60ml of toluene to the three-necked flask, dissolve it at 60°C, add 10.3g of styrene and 0.2g of dodecyl mercaptan, and add dropwise 0.24g of BPO dissolved in it at 80-90°C 40ml of toluene solution was reacted for 6h and then filtered, and the product was vacuum-dried at 80°C for 4h to obtain styrene-maleic anhydride copolymer (SMA).

[0024] Add 100ml of toluene to the three-necked flask, add 64g (0.032mol) of SMA, 8.6g of stearyl alcohol, and 0.5g of p-toluenesulfonic acid, react under reflux for 1h, install a water separator, reflux and divide water for 6h, and obtain the degree of esterification It is 90% styrene-maleic anhydride copolymer octadecyl ester (A).

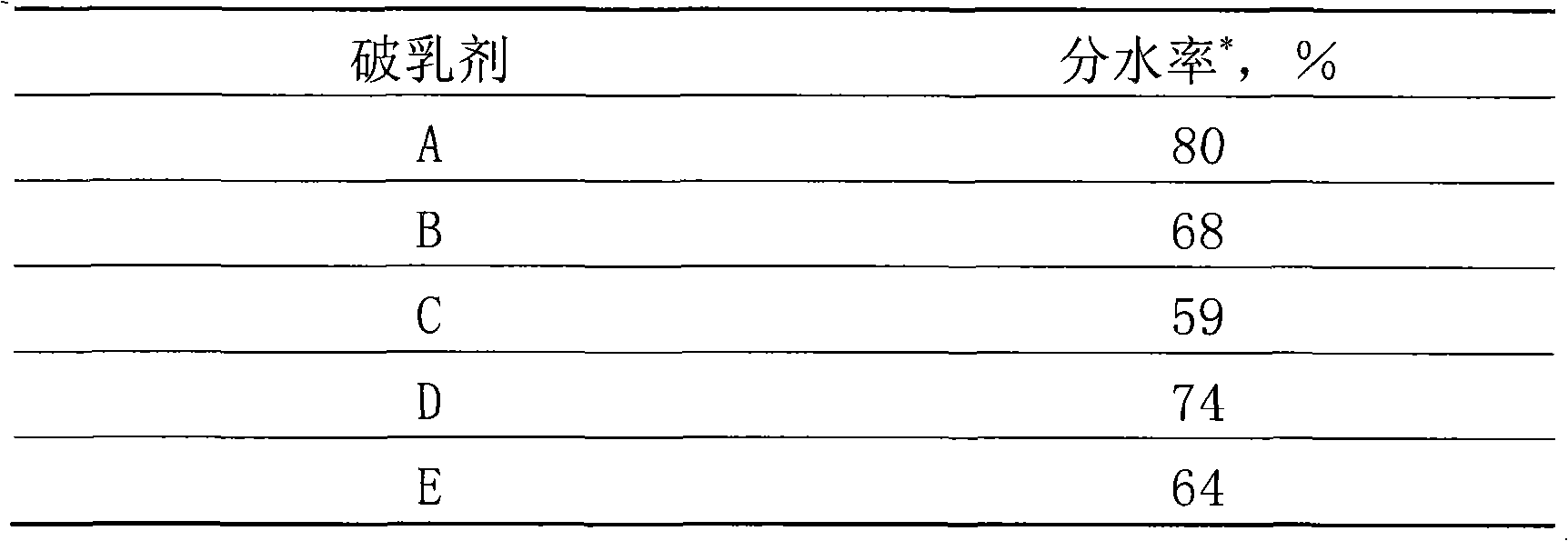

Embodiment 2

[0026] Other conditions were the same as in Example 1, and 7 g of stearyl alcohol was added to obtain a styrene-maleic anhydride copolymer stearyl ester (B) with a degree of esterification of 72%.

Embodiment 3

[0028] Other conditions were the same as in Example 1, and 3.3 g of n-hexanol was added to obtain styrene-maleic anhydride copolymer n-hexyl ester (C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com