High temperature resistant material for cross flow fan of air-conditioning internal machine

A technology of air-conditioning internal unit and cross-flow fan, applied in the field of air-conditioning materials, can solve the problems of increasing noise, affecting the cooling and heating efficiency of air-conditioning, fan deformation, etc., and achieve the effect of alleviating deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

0.4

[0010] The preparation method of embodiment 1-4 is identical, as follows:

[0011] After mixing each raw material in a certain proportion; put it into a high mixer for mixing; then extrude at high temperature with a twin-screw extruder; then cut into materials; the material is injection molded; 24 hours.

[0012] Mixing machine: high speed mixer

[0013] Mixing process: secondary mixing, each mixing time is 6 minutes.

[0014] Production machine: twin-screw extruder

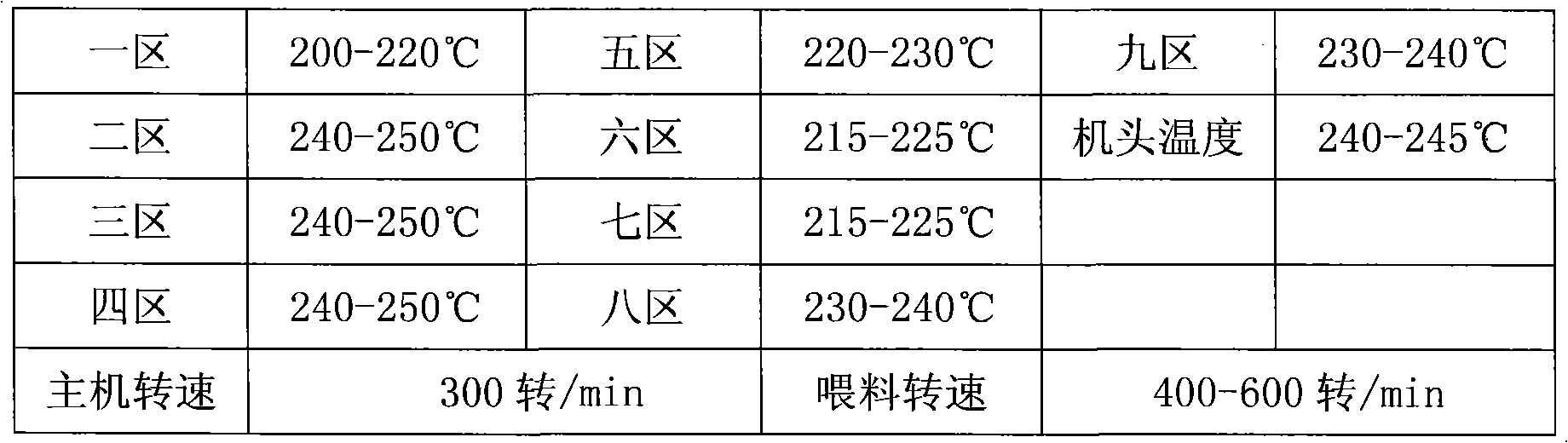

[0015]

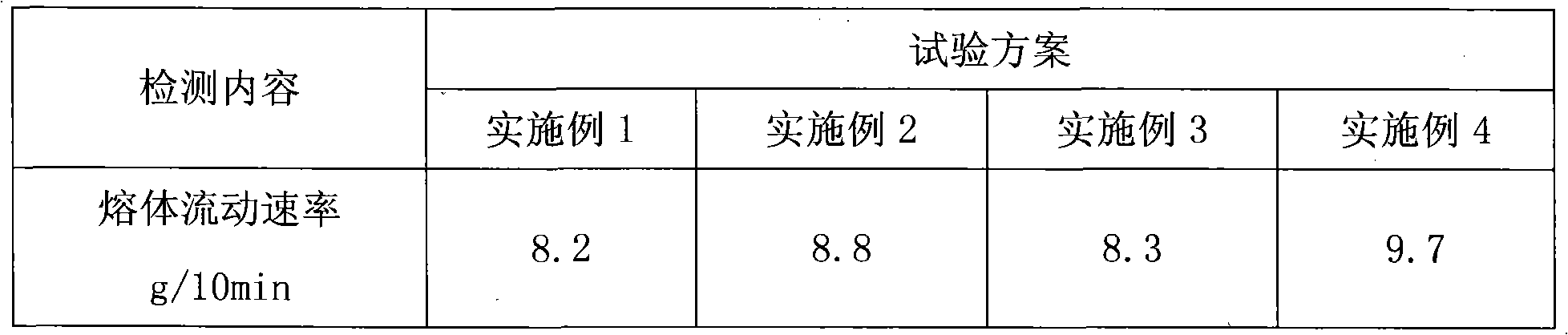

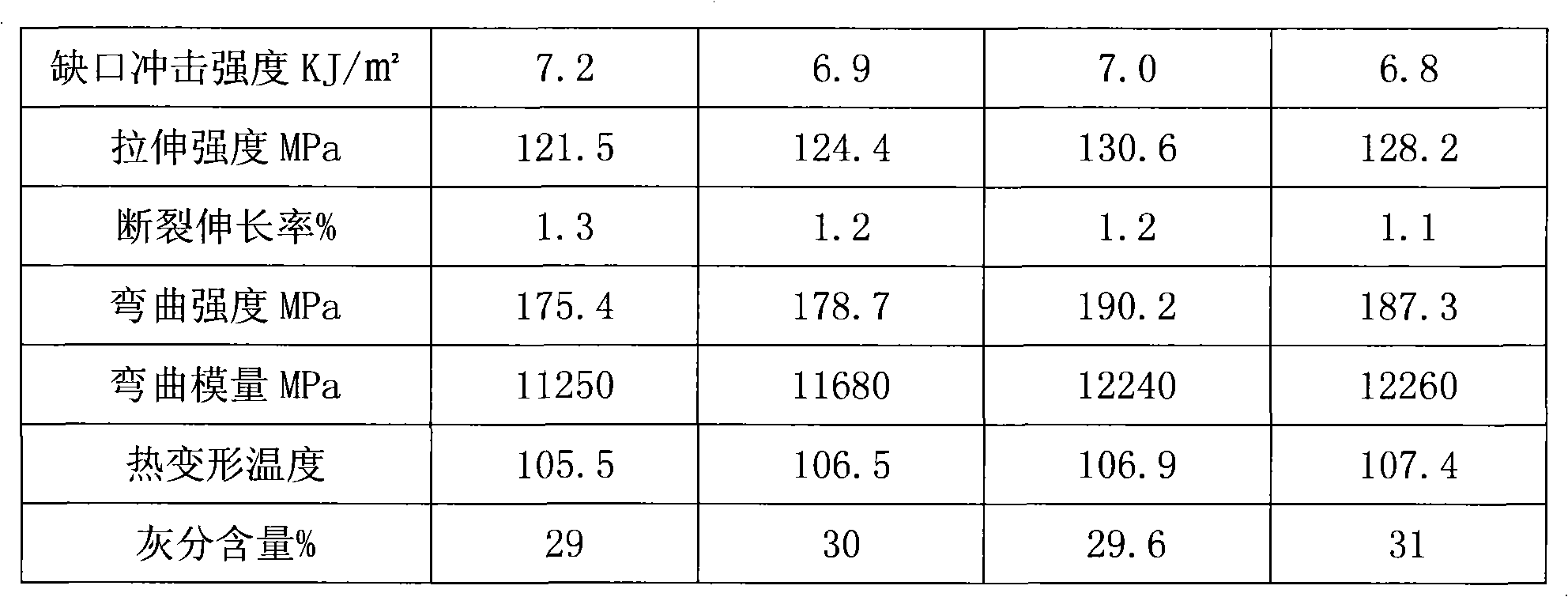

[0016] The performance data of the high temperature-resistant cross-flow fan material of the air conditioner internal unit of embodiment 1-4 are as follows:

[0017]

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com