Suspension type rectangular steel coal bucket bulge reinforcing method

A rectangular steel, hanging technology, used in packaging, transportation and packaging, containers, etc., can solve the problems of conservative design and increased steel consumption in steel coal hoppers, and achieve the effect of relieving the deformation of the bulge, improving the rigidity and improving the rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

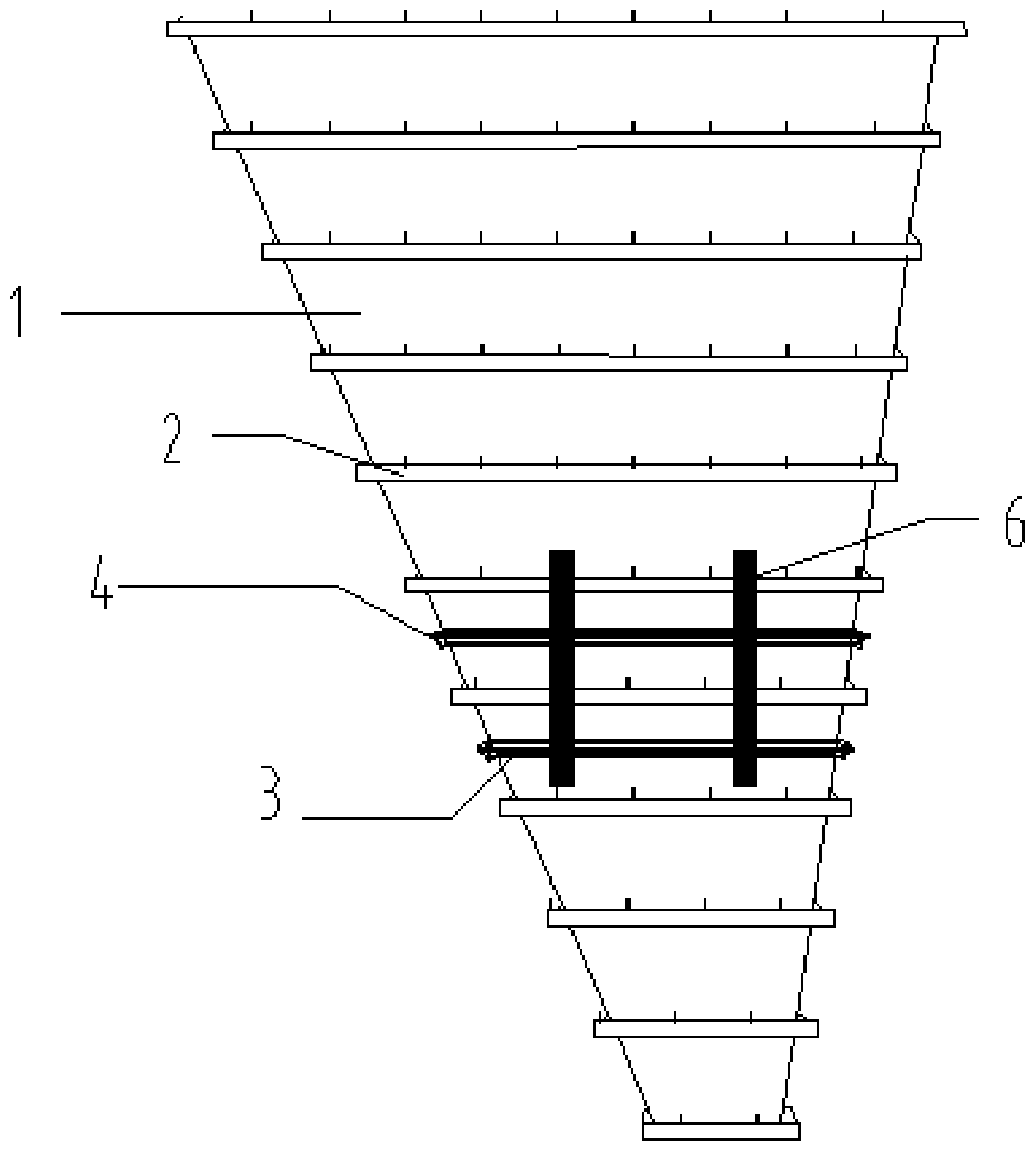

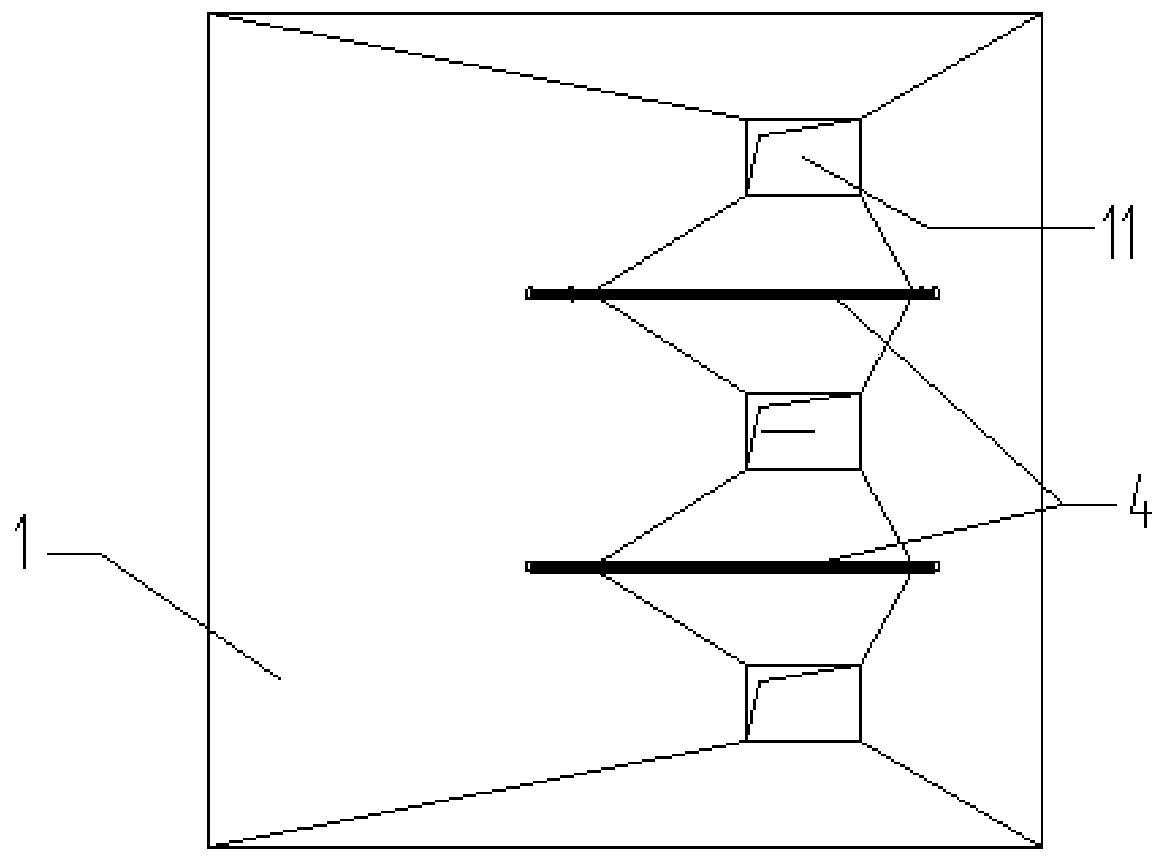

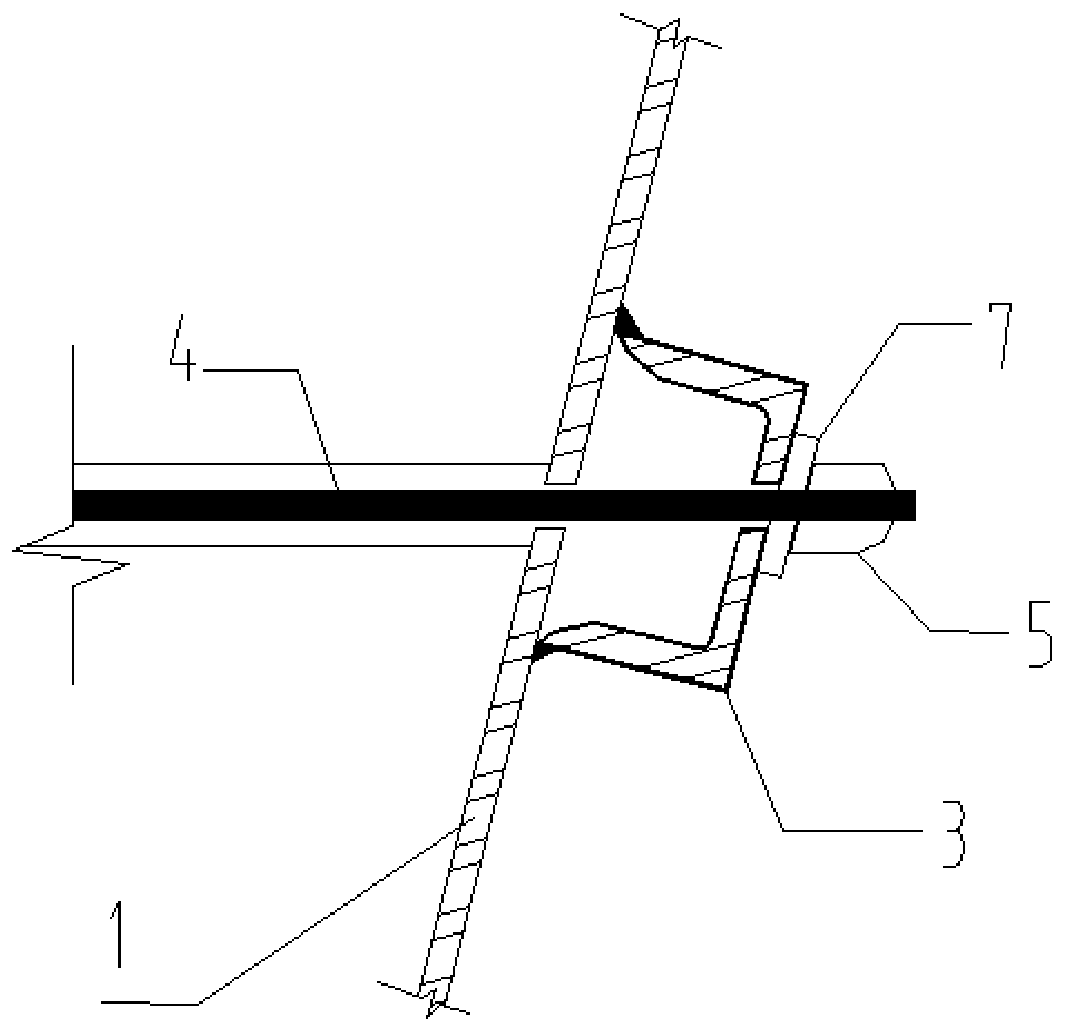

[0038] The invention proposes a method for strengthening the bulge of a suspended rectangular steel coal hopper. In the area where the stress of the conventional suspended rectangular steel coal hopper (that is, welded and fixed with the embedded parts of the upper frame) is the largest, by arranging a reinforcing ring and an inner cable, the shortening is shortened. And change the supporting distance of the steel coal hopper wall in this area, so as to reduce the stress and deformation in this area and achieve the purpose of saving steel.

[0039] A method for strengthening the bulge of a suspended rectangular steel coal hopper, the specific steps are as follows:

[0040]Data collection: On-site investigation, collection of construction drawings, collection of design documents for steel coal scuttles with "bulges", mastering their specific dimensions, materials, and loads, and collecting structural design parameters of steel coal scuttles 1;

[0041] Through on-site investiga...

specific Embodiment example 2

[0065] A method for strengthening the bulge of a suspended rectangular steel coal hopper, the specific steps are as follows:

[0066] Data collection: On-site investigation, collection of construction drawings, collection of design documents for steel coal scuttles with "bulges", mastering their specific dimensions, materials, and loads, and collecting structural design parameters of steel coal scuttles 1;

[0067] Calculation and analysis: According to the data that has been obtained, the finite element structure calculation software is used for modeling analysis to obtain the stress situation and specific location of the "bulge" area of the steel coal hopper;

[0068] Reinforcement scheme design:

[0069] a. First, according to the modeling and analysis results of the finite element structure calculation software, the reinforcement ring 3 is set on the outside of the bucket wall in the height range of the "bulge" area (that is, the area where the stress is concentrated), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com