Method for carrying out graft modification on graphene by virtue of styrene-maleic anhydride copolymer

A technology of maleic anhydride and graft modification is applied in the field of preparation of new carbon materials, which can solve the problems of high reaction temperature, long reaction time, and unclear application direction, and achieve the effect of good dispersion and improved mechanics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

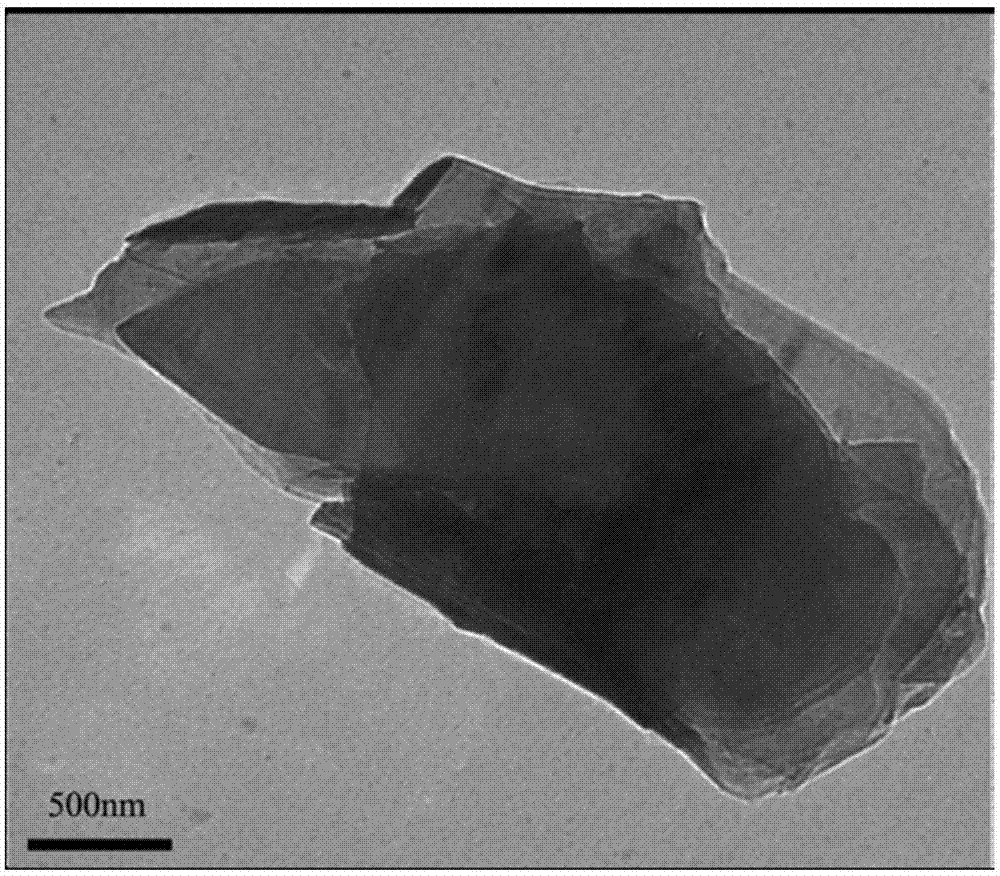

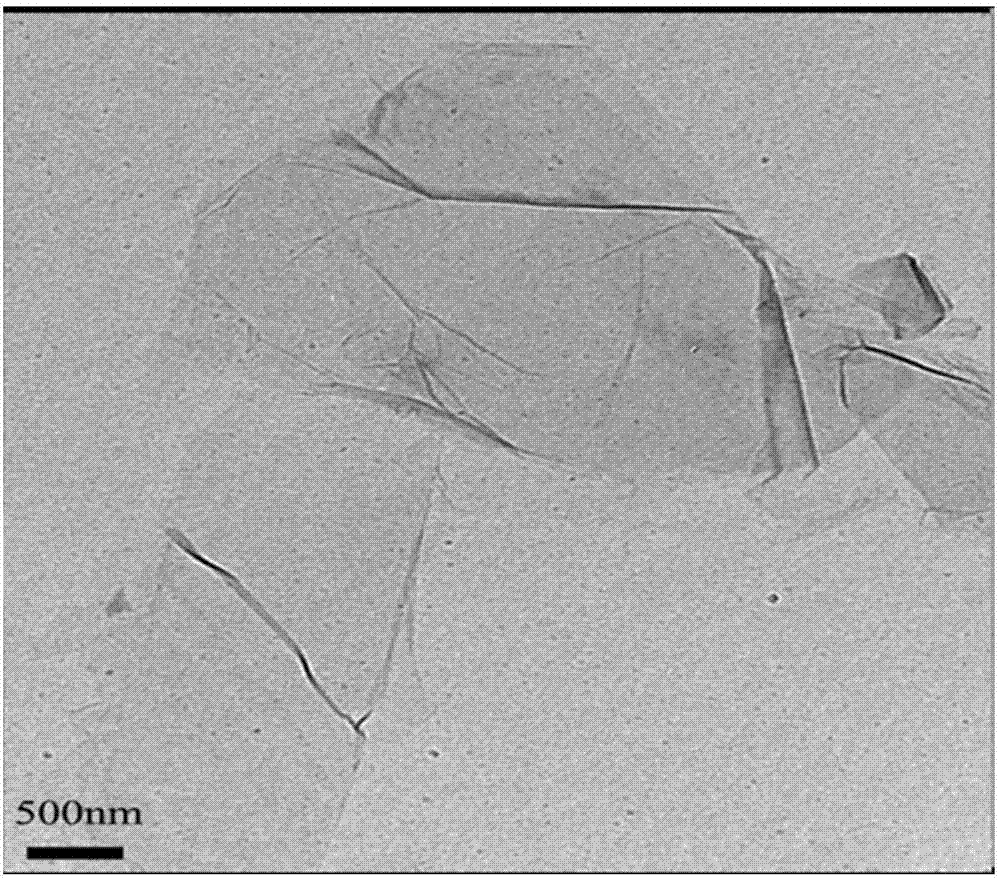

[0021] (1) Preparation of graphene oxide: graphene oxide (GO) prepared by the improved Hummers' method; the main functional groups contained on the surface of graphene oxide are hydroxyl, carboxyl and epoxy groups;

[0022] (2) Preparation of maleic anhydride grafted graphene oxide: the graphene oxide and maleic anhydride obtained in step 1) are dispersed in an organic solvent to make a suspension, and the hydroxyl group on the graphene oxide surface is formed at 35- React with maleic anhydride at 80°C for 3-6 hours, and use monomer grafting to graft maleic anhydride onto graphene oxide; the mass ratio of graphene oxide to maleic anhydride is 1:10-1:30; The organic solvent is at least one of toluene, benzene, N,N-dimethylformamide or N,N-dimethylacetamide;

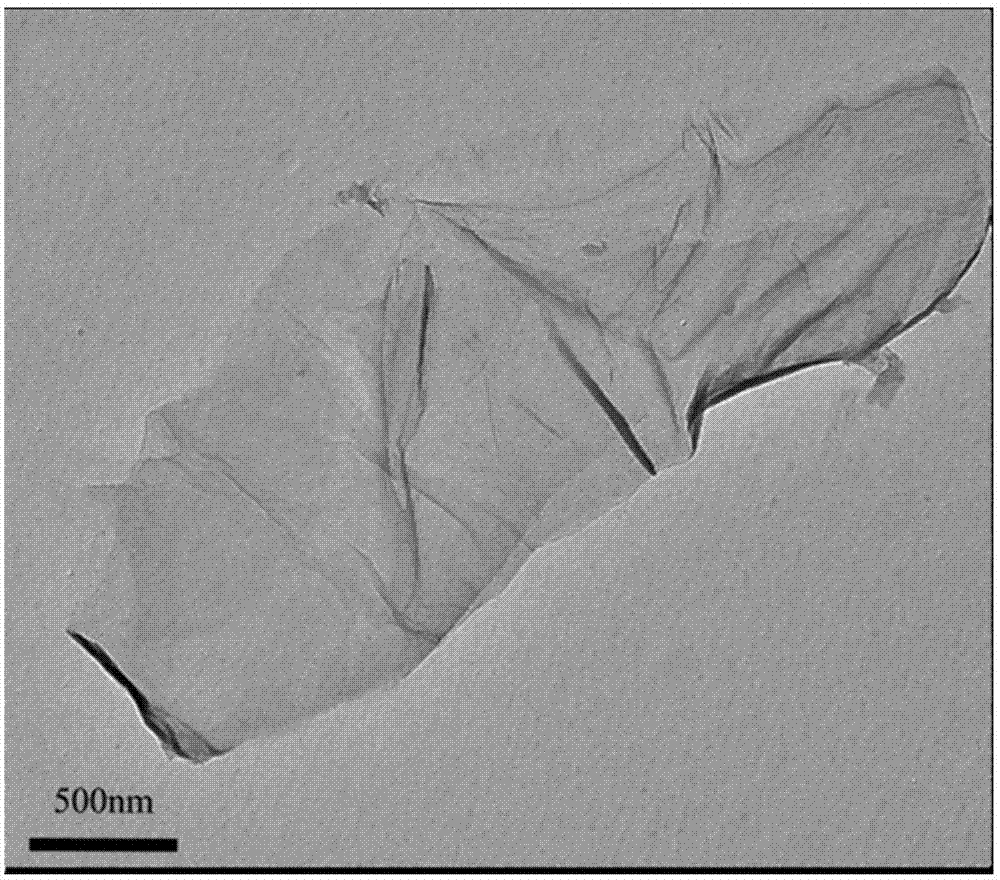

[0023] (3) Preparation of styrene-maleic anhydride copolymer grafted graphene oxide: with the graphene oxide grafted with maleic anhydride obtained in step 2) as raw material, add a free radical initiator, and mix with St...

Embodiment 1

[0043] (1) Preparation of graphene oxide: graphene oxide prepared by improved Hummers' method;

[0044] (2) Preparation of maleic anhydride grafted graphene oxide: disperse 0.2g graphene oxide and 6.0g maleic anhydride in toluene to make a suspension, react at 80°C for 3 hours, and graft maleic anhydride onto graphene oxide;

[0045] (3) Preparation of styrene-maleic anhydride copolymer grafted graphene oxide: 0.2g AIBN, 5g styrene, and 4.8g maleic anhydride were added to maleic anhydride grafted graphene oxide, and reacted at 80°C 1 hour; the reaction product was ultrasonically washed three times with acetone, centrifuged and then vacuum-dried at 80° C. to obtain styrene-maleic anhydride copolymer grafted graphene oxide.

[0046] TGA analysis showed that the effective grafting rate was 23.7%.

Embodiment 2

[0048] (1) Preparation of graphene oxide: graphene oxide prepared by improved Hummers' method;

[0049] (2) Preparation of maleic anhydride grafted graphene oxide: disperse 0.2g graphene oxide and 2.0g maleic anhydride in toluene to make a suspension, react at 60°C for 3 hours, and graft maleic anhydride onto graphene oxide;

[0050] (3) Preparation of styrene-maleic anhydride copolymer grafted graphene oxide: 0.2g BPO, 2g styrene, and 2g maleic anhydride were added to maleic anhydride grafted graphene oxide, and reacted at 70°C for 3 Hours; the reaction product was ultrasonically washed three times with acetone, centrifuged and then vacuum-dried at 80° C. to obtain styrene-maleic anhydride copolymer grafted graphene oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com