Halogen-free high frequency resin composition

A resin composition and high-frequency technology, which is applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of heat resistance limiting the development of HDI, substrate explosion, and low bond energy. Achieve the effects of improving processing stability and reliability, low dielectric constant, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

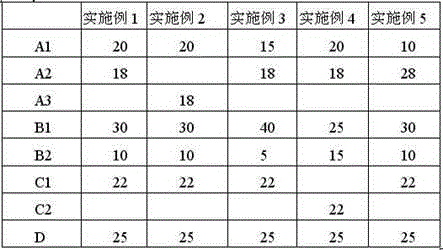

[0027] For the above-mentioned relevant properties, it can be illustrated and described according to the following examples and comparative examples, including the following examples 1-7 and comparative examples 1-3.

[0028] The proportion of related substances is based on 100 parts by weight of organic substances such as A1, A2, A3, B1, B2, C1, C2, and D in the components, and the proportion of other components is the proportion of the total weight of the organic substances.

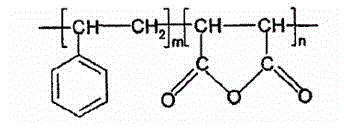

[0029] (A1) Styrene-maleic anhydride copolymer SMA-EF30(m:n=3:1)

[0030] (A2) Phenolphthalein-type benzoxazine

[0031] (A3) Bisphenol A benzoxazine

[0032] (B1) Dicyclopentadiene type (DCPD modified) epoxy resin

[0033] (B2) Trifunctional epoxy resin

[0034] (C1) Phosphorus-containing phenolic resin

[0035] (C2) Phosphate

[0036] (D) Fused Silica Powder

[0037] The structural formula of this trifunctional epoxy resin is as follows:

[0038]

[0039] The laminate base material of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com