Patents

Literature

36results about How to "Low dielectric loss value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin composition as well as prepreg and copper-foil-clad laminated board prepared by using same

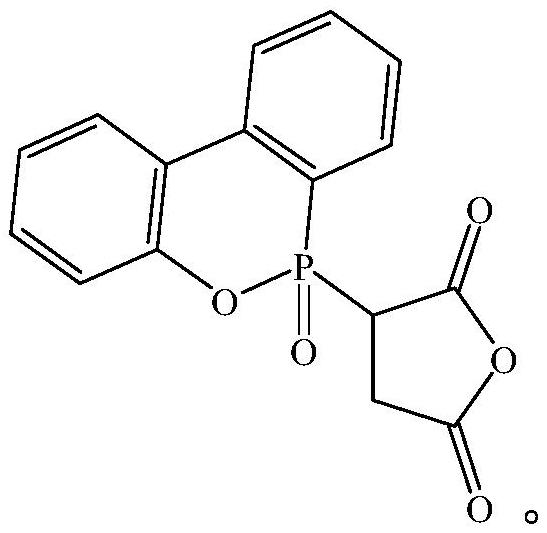

InactiveCN102443138AHigh glass transition temperatureHigh functionalitySynthetic resin layered productsMetal layered productsEpoxyDielectric loss

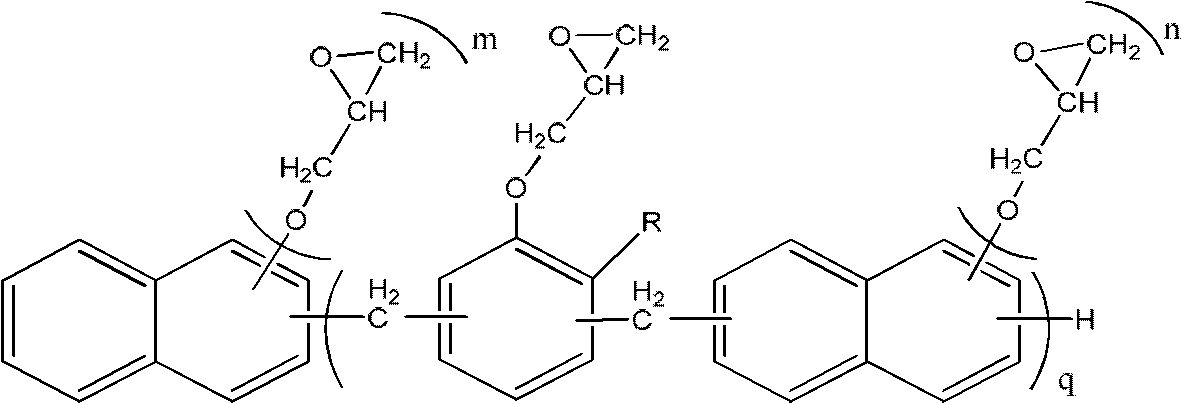

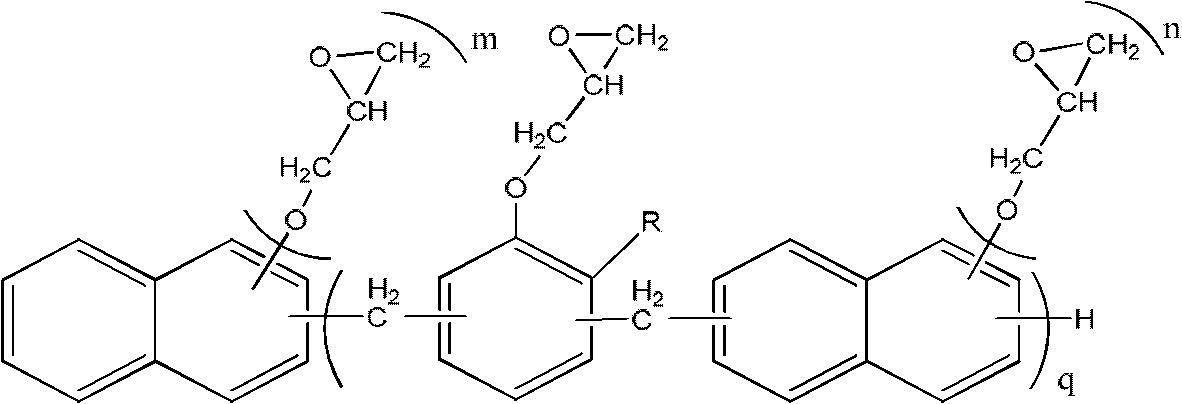

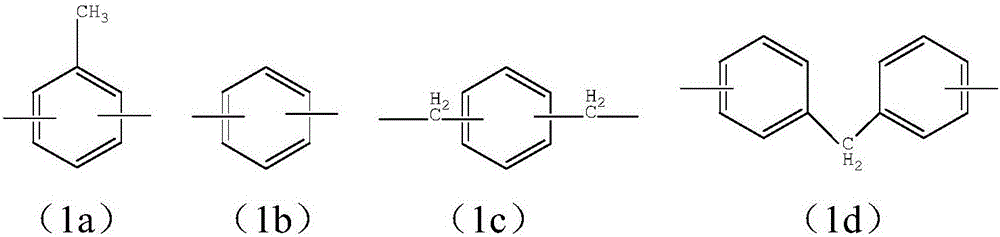

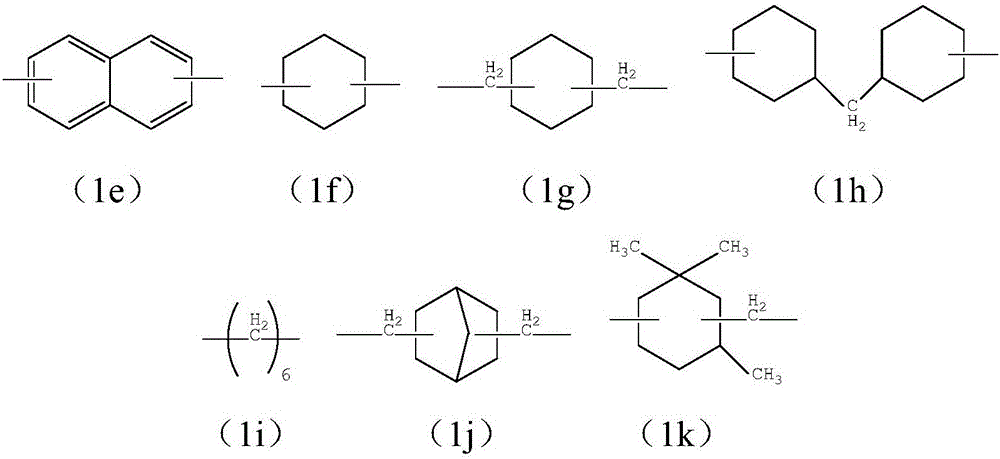

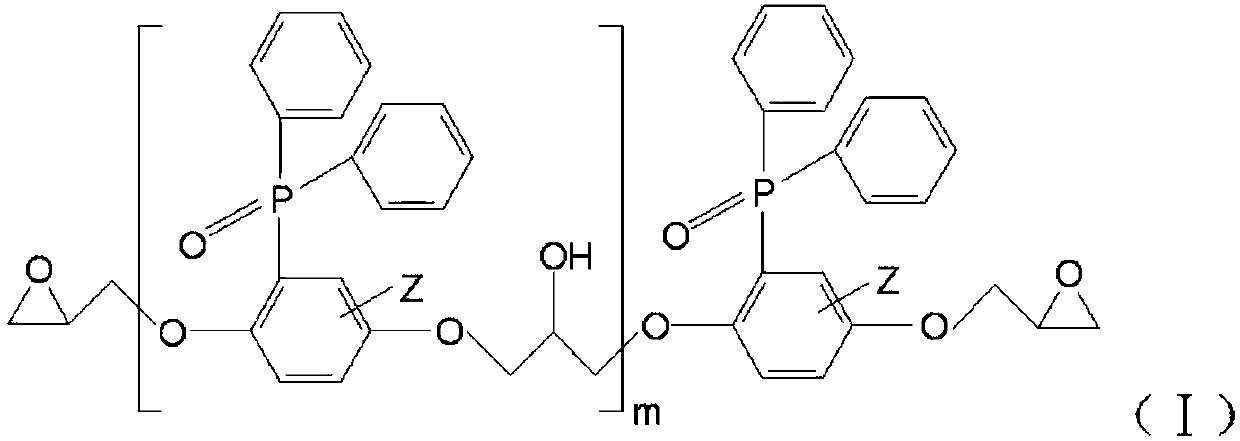

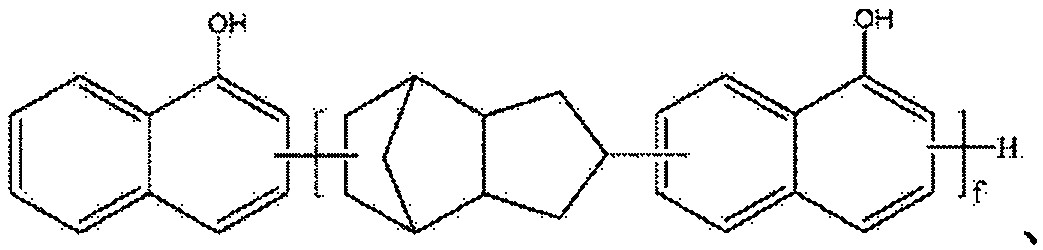

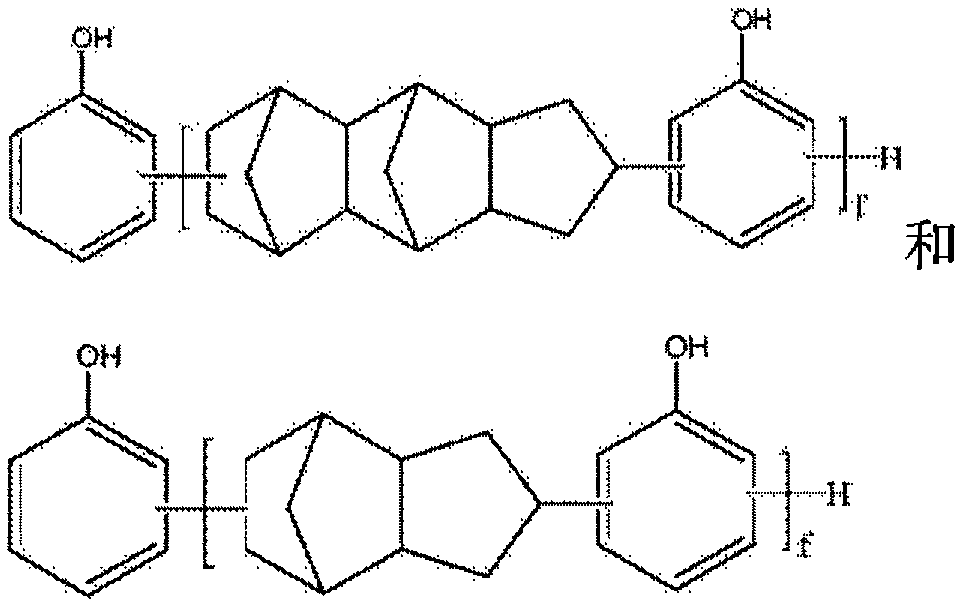

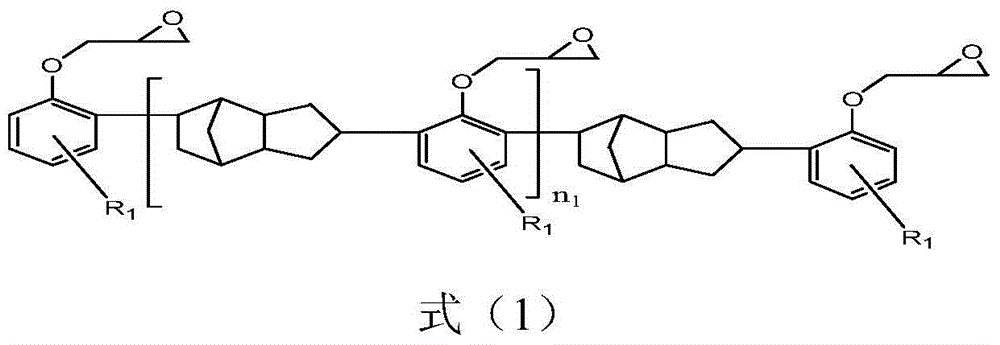

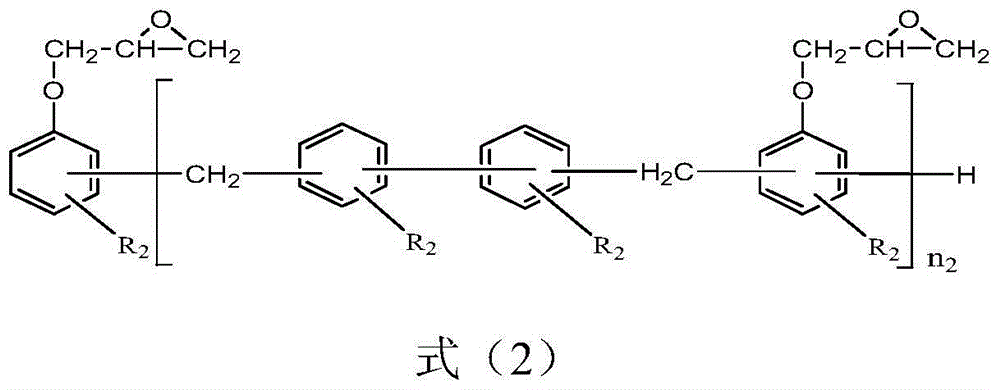

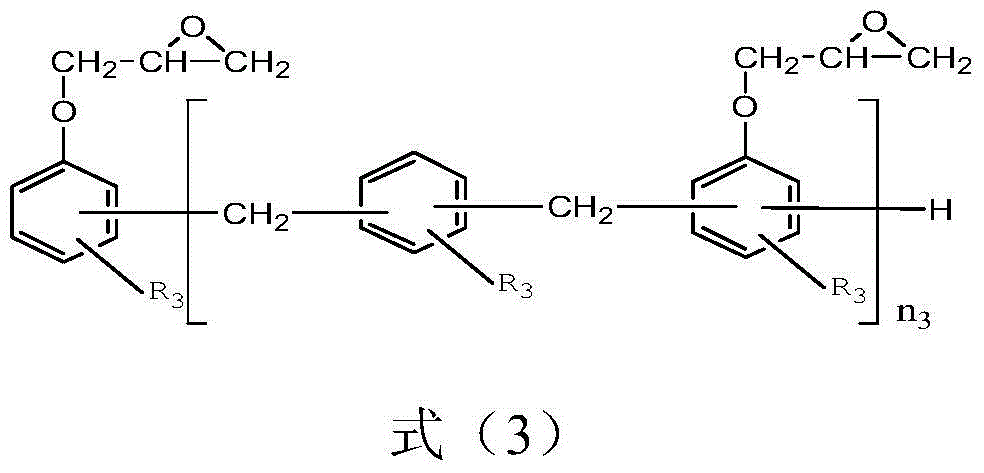

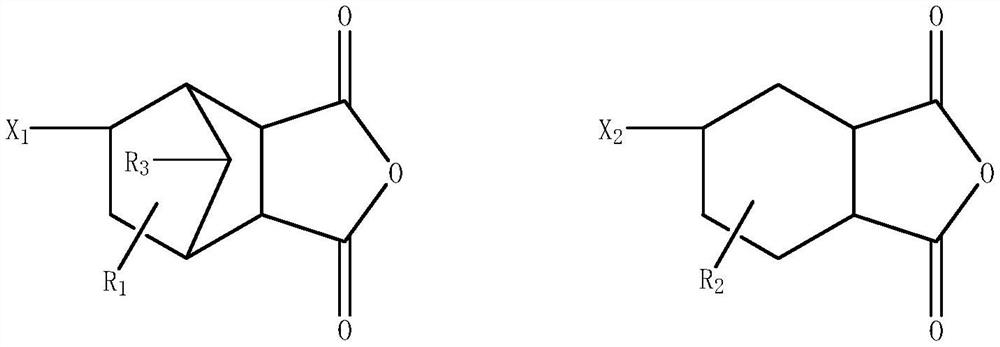

The invention relates to an epoxy resin composition as well as a prepreg and a copper-foil-clad laminated board prepared by using the same. The epoxy resin composition comprises the following essential components: (A) epoxy resin containing a naphthol structure, (B) an active ester serving as a curing agent, and (C) a curing accelerant. Because epoxy resin at least contains the naphthol structure in the molecular structure, the epoxy resin composition provided by the invention has higher functionality degree and high glass transition temperature; at the same time, the naphthol group structure is introduced to the molecular structure, thus the cured product has low water absorptivity and low expansion coefficient; due to the active ester serving as the curing agent, the advantages that the a polar group is not generated during the reaction between the active ester and epoxy, thus the dielectric properties are excellent and moisture and heat resistance are good are fully exerted; and in addition, because of the epoxy resin containing the special naphthol structure, the hydroscopicity of the resin cured product is further reduced and the dielectric loss value of the cured product is lowered. The prepreg and the copper-foil-clad laminated board provided by the invention have excellent dielectric properties, moisture and heat resistance and high glass transition temperature.

Owner:GUANGDONG SHENGYI SCI TECH

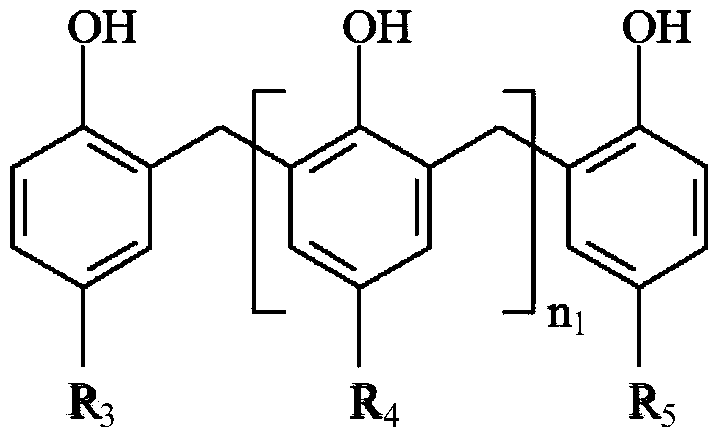

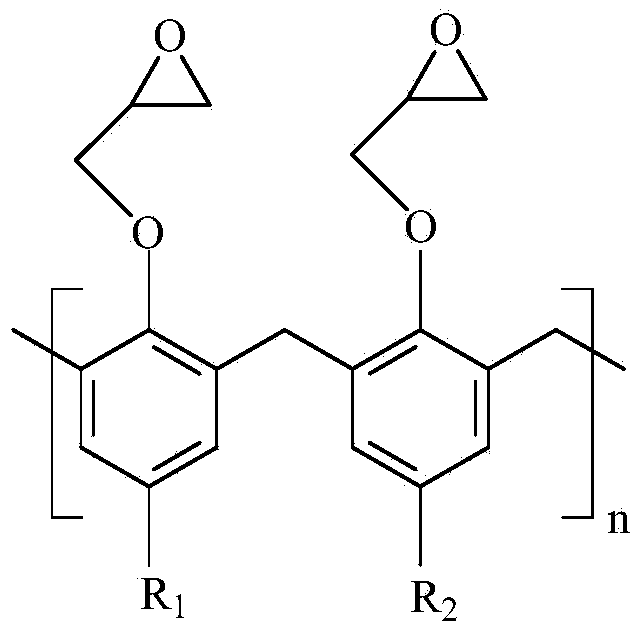

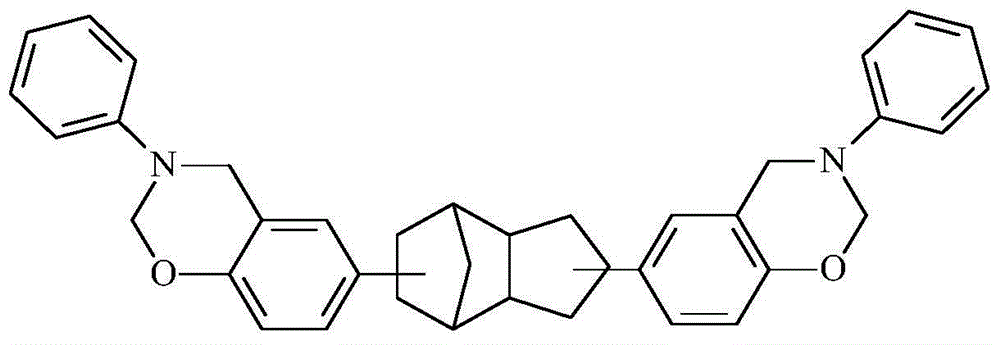

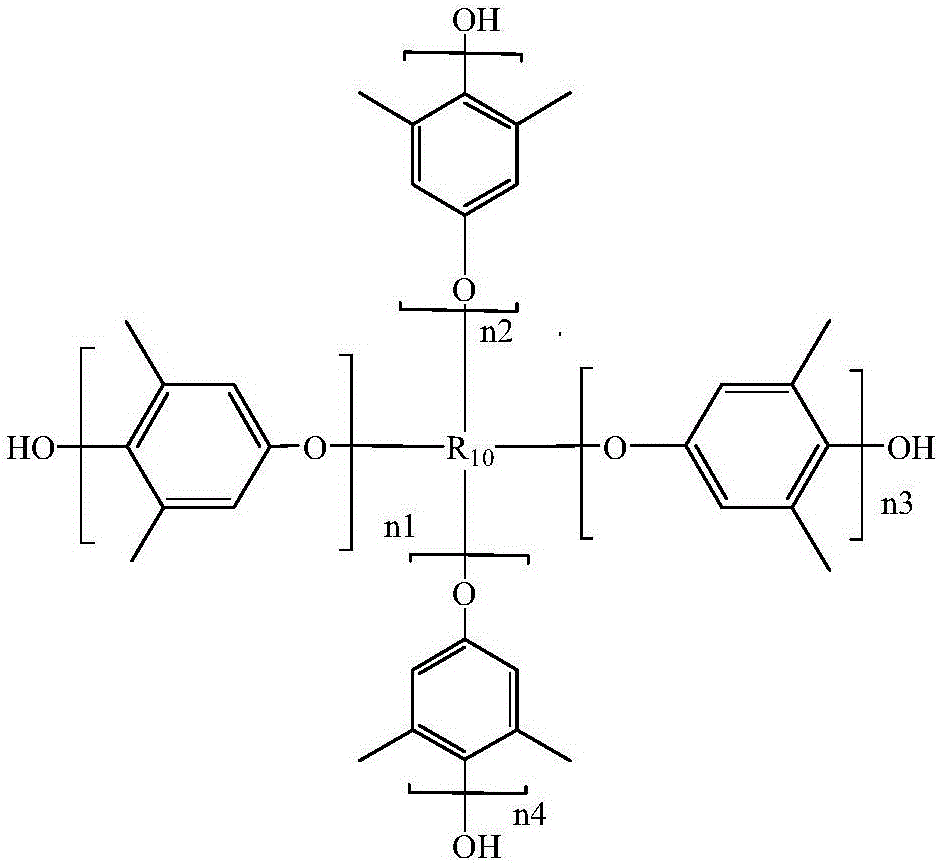

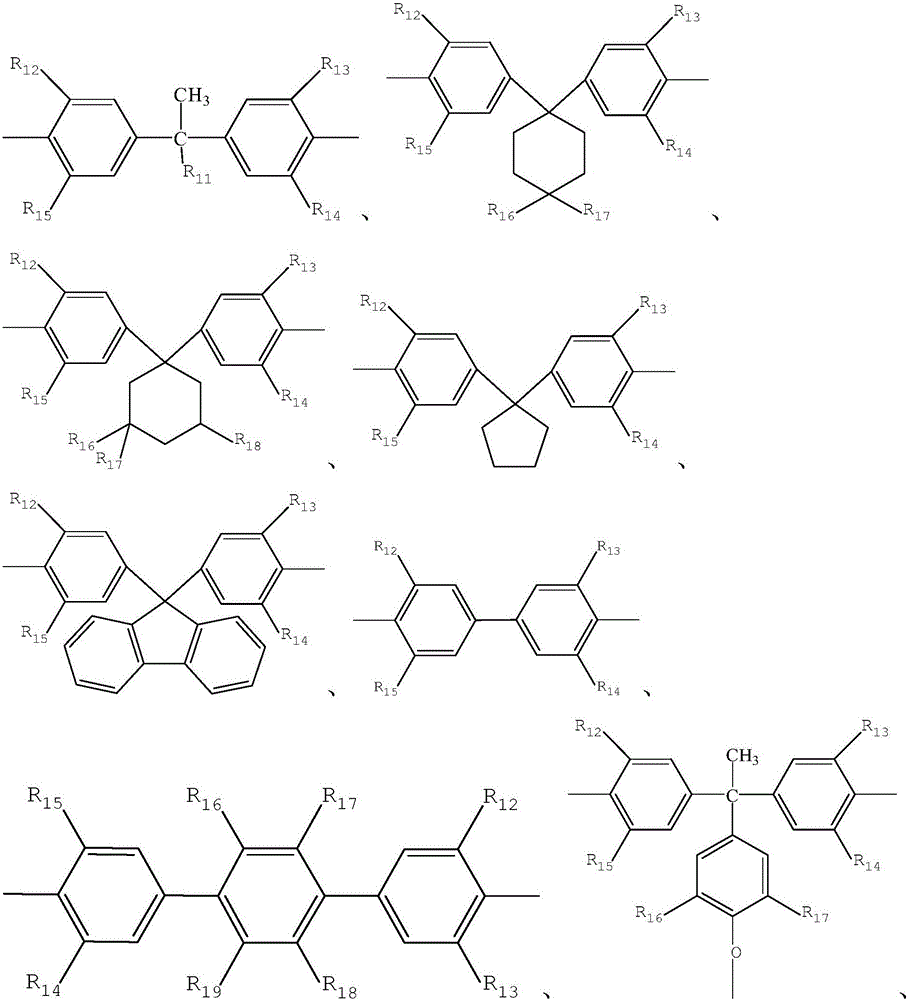

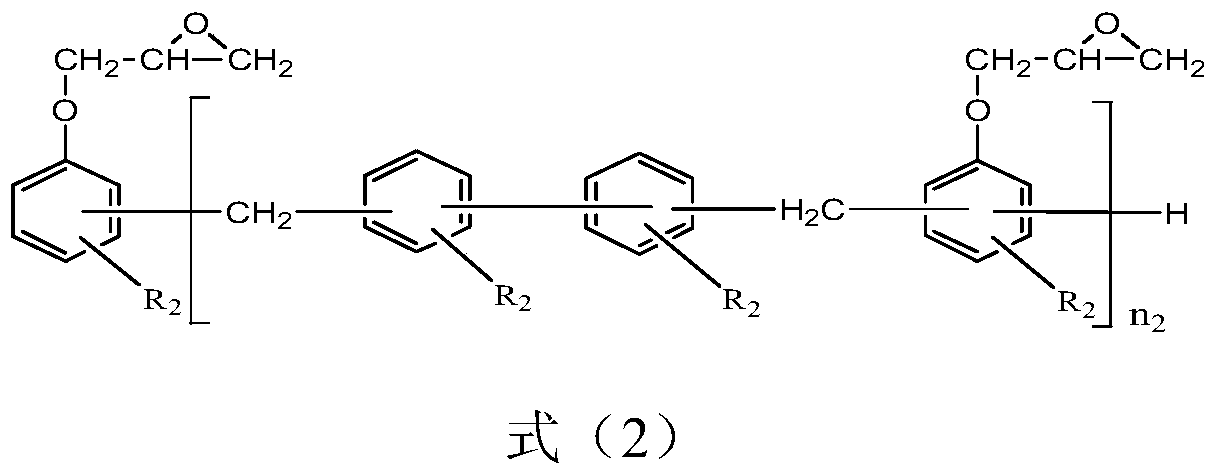

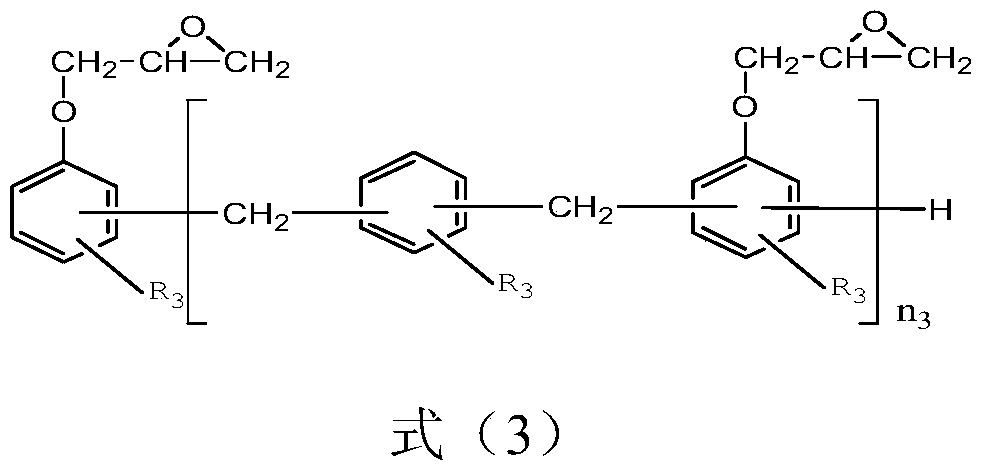

Halogen-free resin composition, prepreg prepared from halogen-free resin composition and laminated board prepared from halogen-free resin composition and used for printed circuit

ActiveCN103992622ALow dielectric constantReduce lossSynthetic resin layered productsCircuit susbtrate materialsAlkylphenolAbsorption rate

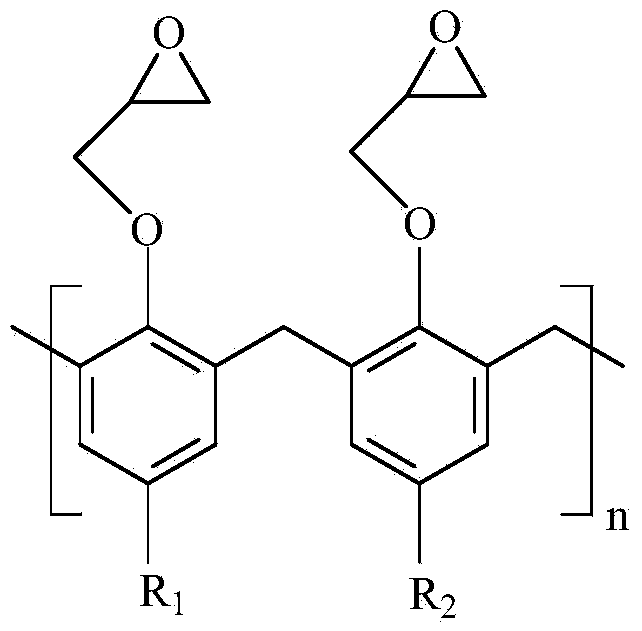

The invention discloses a halogen-free resin composition, a prepreg prepared from the halogen-free resin composition and a laminated board prepared from the halogen-free resin composition and used for a printed circuit. The halogen-free resin composition comprises alkylphenol epoxy resin, benzoxazine resin, an alkylphenol aldehyde curing agent and a phosphorus-contained flame retardant. The molecular structure of alkylphenol epoxy resin adopted in the halogen-free resin composition contains more branched alkyls, so that the halogen-free resin composition is relatively high in glass transition temperature, low in water absorption rate, favorable in heat resistance and excellent in dielectric performance; benzoxazine resin is mixed, so that the dielectric constant, dielectric loss value and water absorption rate of a solid can be further reduced; alkylphenol aldehyde is used as a curing agent, so that the advantages of excellent dielectric performance and low water absorption rate generated by more alkyls in the structure are sufficiently exerted. The prepreg prepared from the halogen-free resin composition and the laminated board prepared from the halogen-free resin composition and used for the printed circuit have the advantages of low dielectric constant, low dielectric loss factor, low water absorption rate, high size stability, high heat resistance, and favorable flame retardance, processability and chemical resistance.

Owner:江西生益科技有限公司

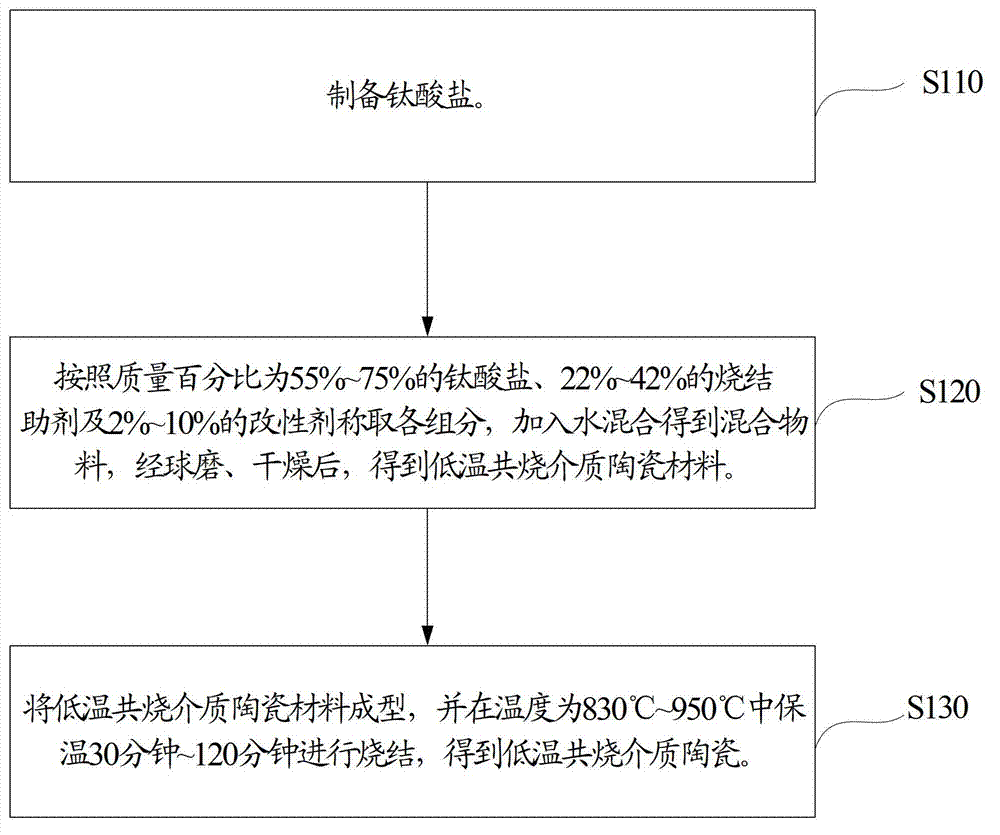

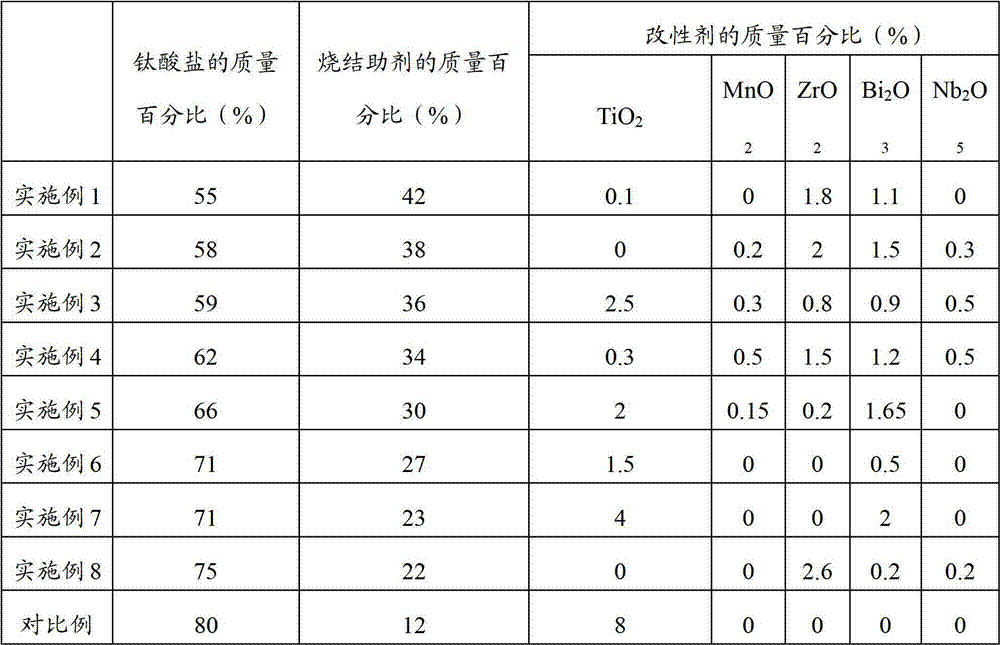

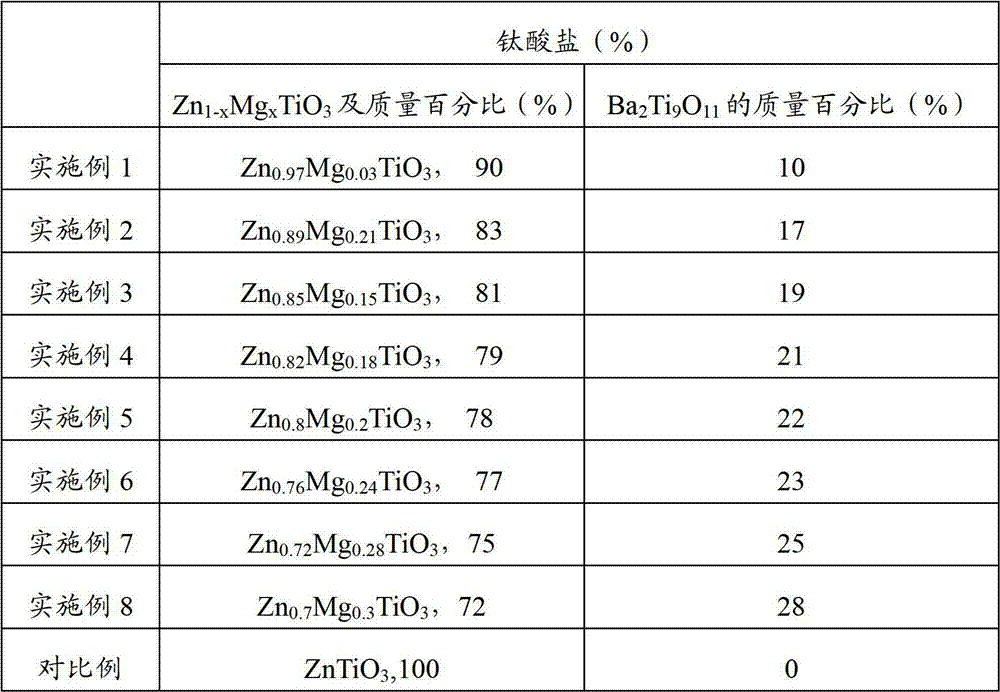

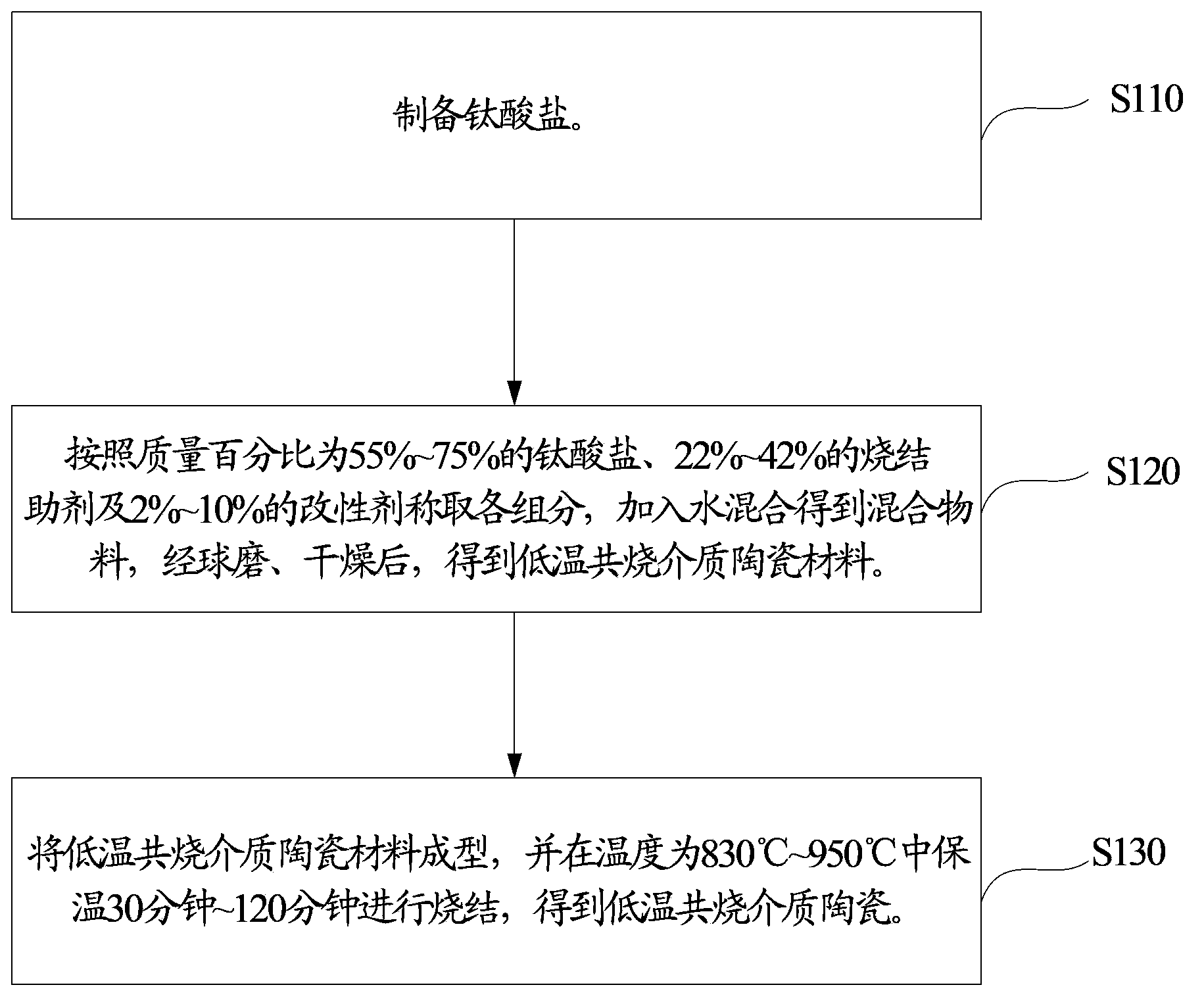

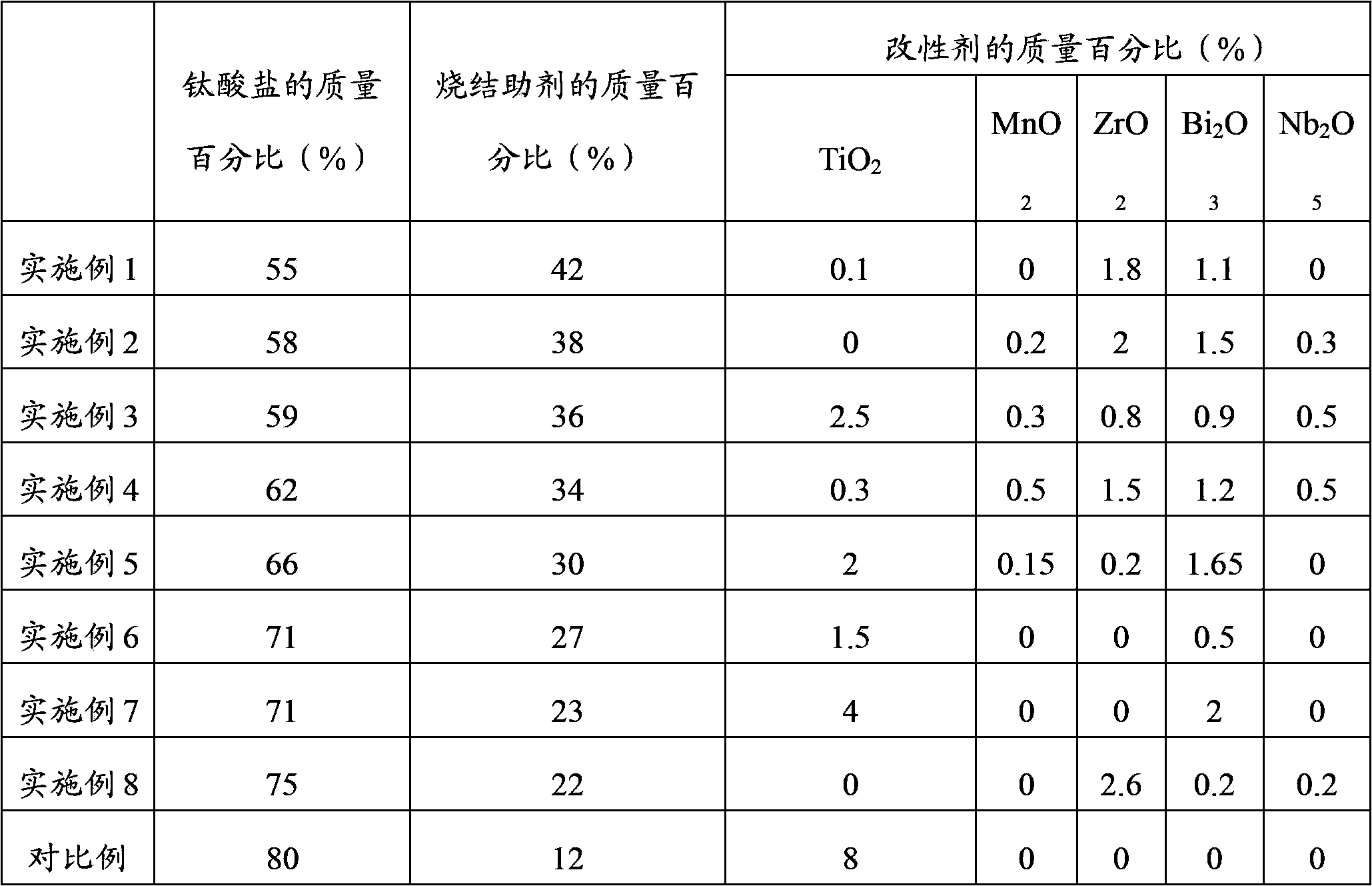

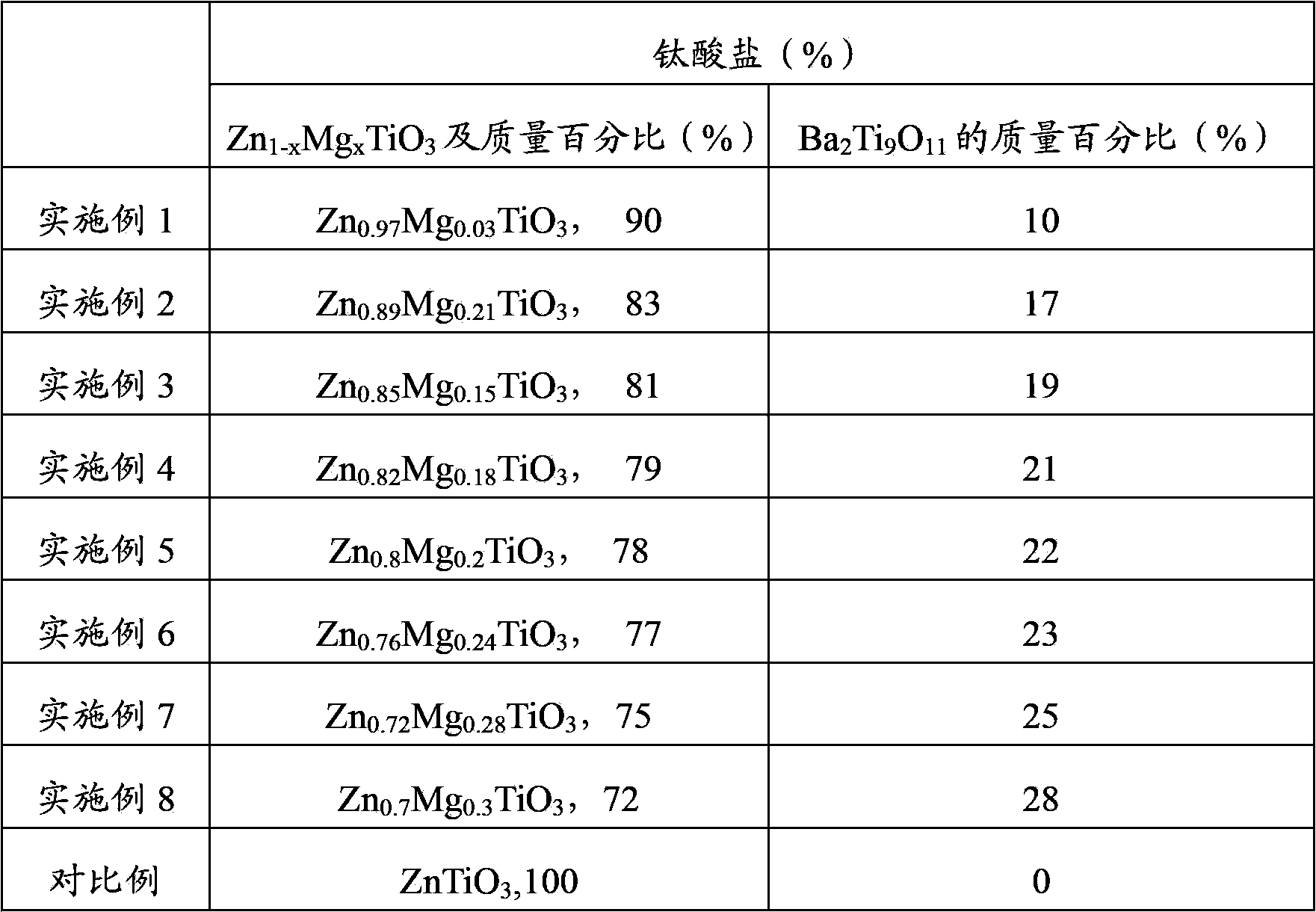

Method for preparing low-temperature cofired dielectric ceramic and material and sintering aid of low-temperature cofired dielectric ceramic

The invention relates to a sintering aid for a low-temperature cofired dielectric ceramic material. The sintering aid comprises the following components in percentage by mass: 40 to 55 percent of silicon dioxide, 5 to 16 percent of boron oxide, 12 to 17 percent of zinc oxide, 5 to 15 percent of aluminum oxide, 3 to 10 percent of lithium oxide, 0 to 5 percent of copper oxide, 0 to 5 percent of cobaltosic oxide and 3 to 8 percent of oxides of which the general formula is R2O3, wherein R may be at least one of lanthanum, neodymium, samarium and dysprosium. By the sintering aid for the low-temperature cofired dielectric ceramic material, the low-temperature cofired dielectric ceramic material can be sintered at temperature of between 830 and 950 DEG C, and the dielectric performance of the low-temperature cofired dielectric ceramic is improved effectively. In addition, the invention also provides the low-temperature cofired dielectric ceramic material and a method for preparing the low-temperature cofired dielectric ceramic.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

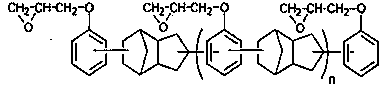

Bimaleimide foam material and preparation thereof

InactiveCN101343413AImprove heat resistanceExcellent dielectric propertiesDiphenylmethanePolymer science

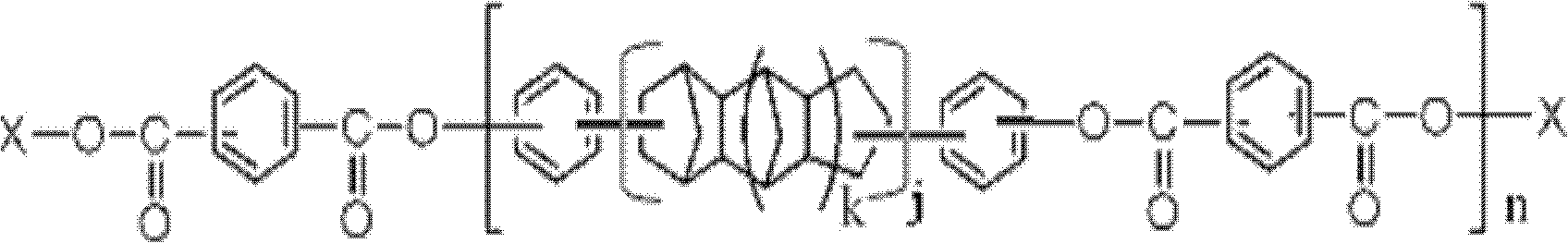

The invention discloses bismaleimide foaming material and the preparation method. The bismaleimide foaming material is composed of 100 parts of N, N`-4, 4`-diphenylmethane bismaleimide / O, O`-diallyl bisphenol A performed polymer and 3 to 12 parts of foaming agent. The preparing method adopts 100 parts of bismaleimide and 43 parts to 103 parts of diallyl bisphenol A resin to be mixed at the temperature of 120 DEG C to 150 DEG C to obtain the performed polymer, 3 to 12 parts of foaming agent are added into the performed polymer per 100 parts of the performed polymer and are evenly mixed, the mixture is positioned into a preheating die, is foamed at 140 DEG C to 180 DEG C for 35 to 10 min, is solidified at the temperature of 140 to 200 DEG C for 4 hours to 8 hours and then is processed at the temperature of 220 DEG C to 240 DEG C for 4 hours to 10 hours, to obtain the bismaleimide foaming material with high performance. The bismaleimide foaming material can be applied to occasions where the requirements for lightness, heat resistance and dielectric properties and mechanical properties of the material are high and also can be served as core material for forming composite material with high performance.

Owner:SUZHOU UNIV

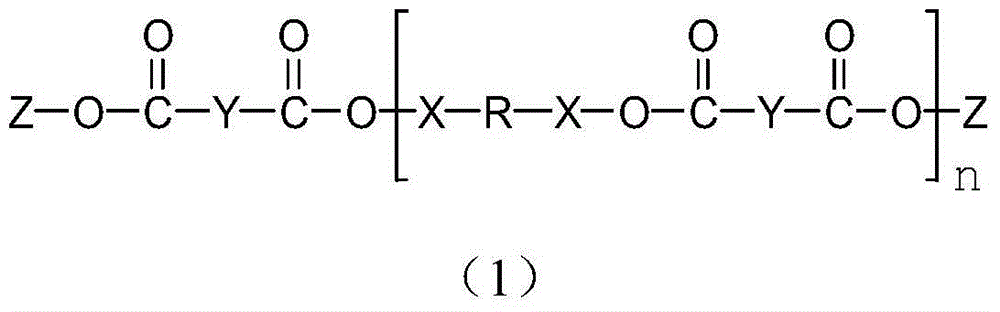

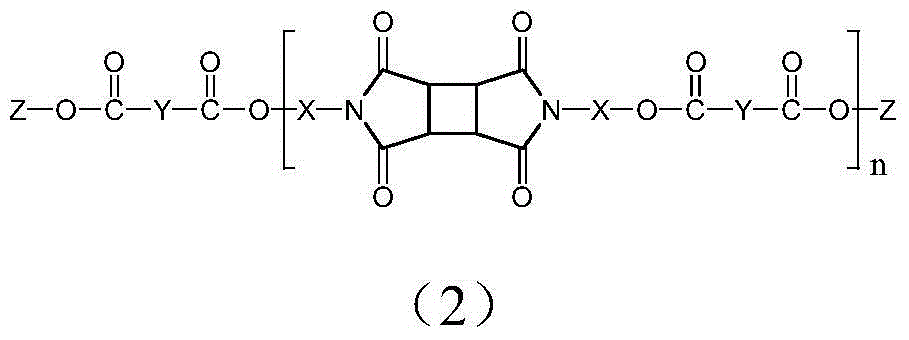

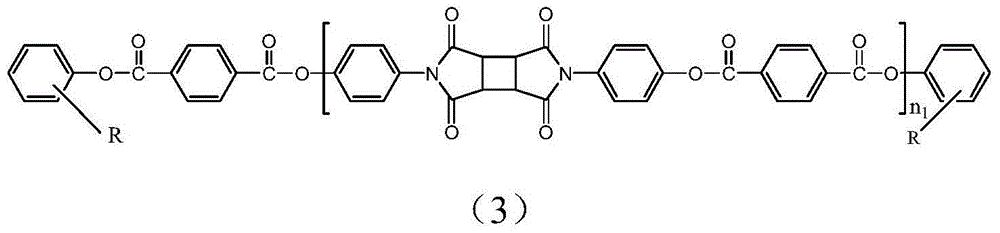

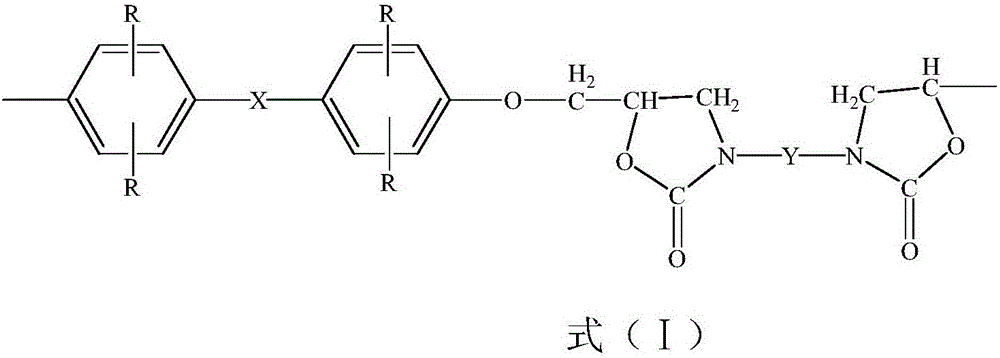

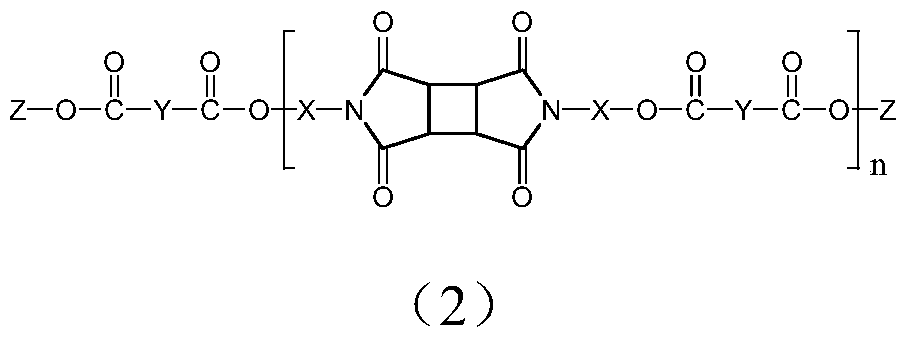

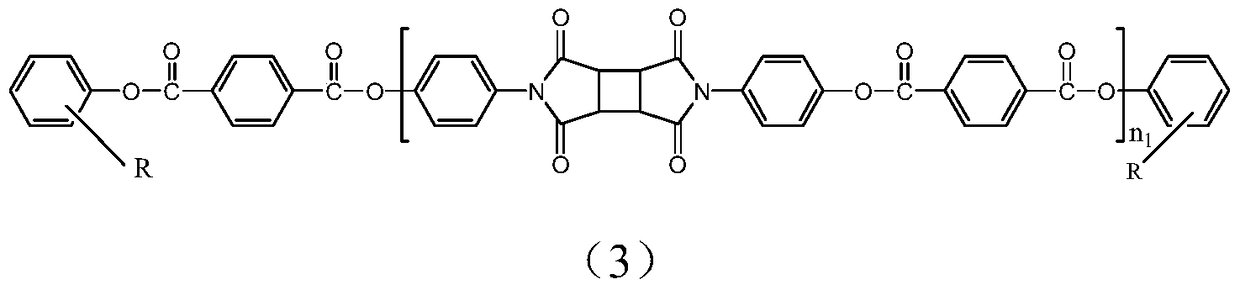

Epoxy resin composition, and prepreg and laminated board with epoxy resin composition

ActiveCN105778430AEasy to processImprove solubilitySynthetic resin layered productsCircuit susbtrate materialsEpoxySolubility

The invention relates to an epoxy resin composition, and a prepreg and a laminated board with the epoxy resin composition. The epoxy resin composition comprises imide-modified active ester and epoxy resin. The imide-modified active ester resin composition has good process workability and solubility. With the composition, the advantages of no secondary hydroxyl generation and intrinsic good dielectric properties of active ester resin cured epoxy resin are maintained. Also, imide group with better heat resistance is introduced into the main chain, such that the heat resistance of existing active ester is improved. The prepreg and laminated board prepared with the composition has the advantages of high glass transition temperature, low dielectric constant, low dielectric loss value and low water absorption.

Owner:GUANGDONG SHENGYI SCI TECH

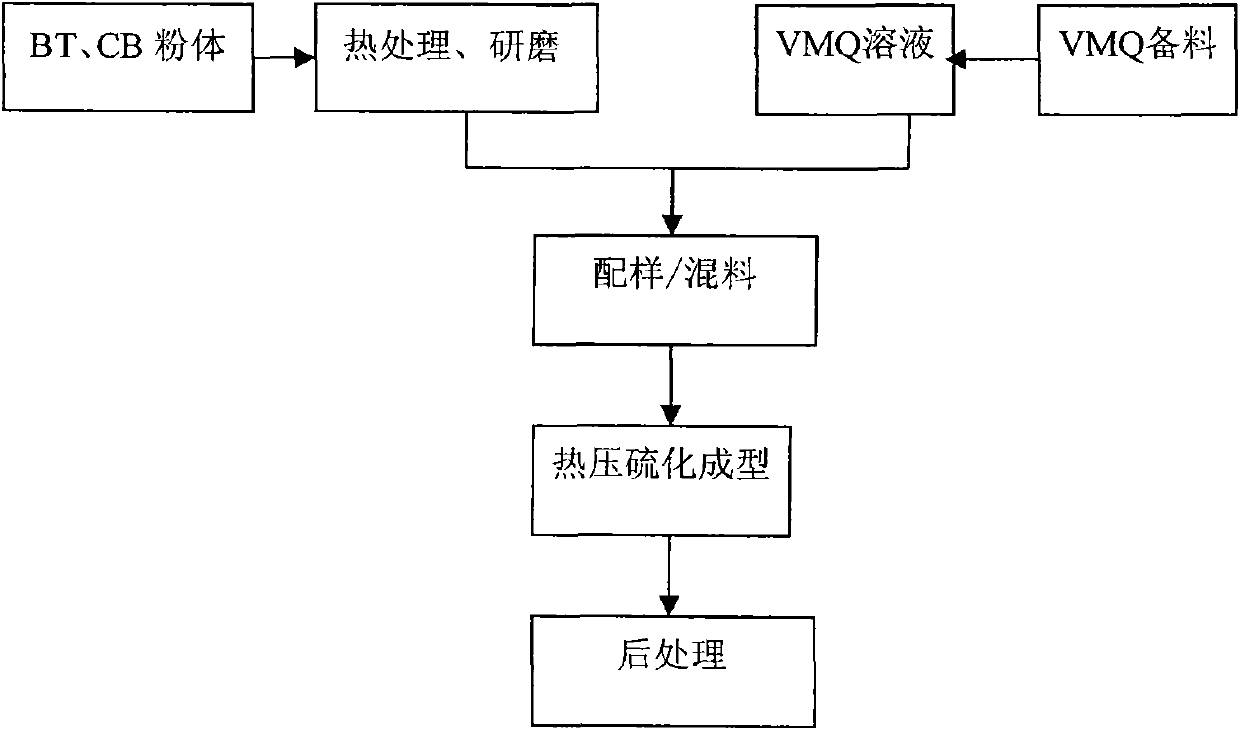

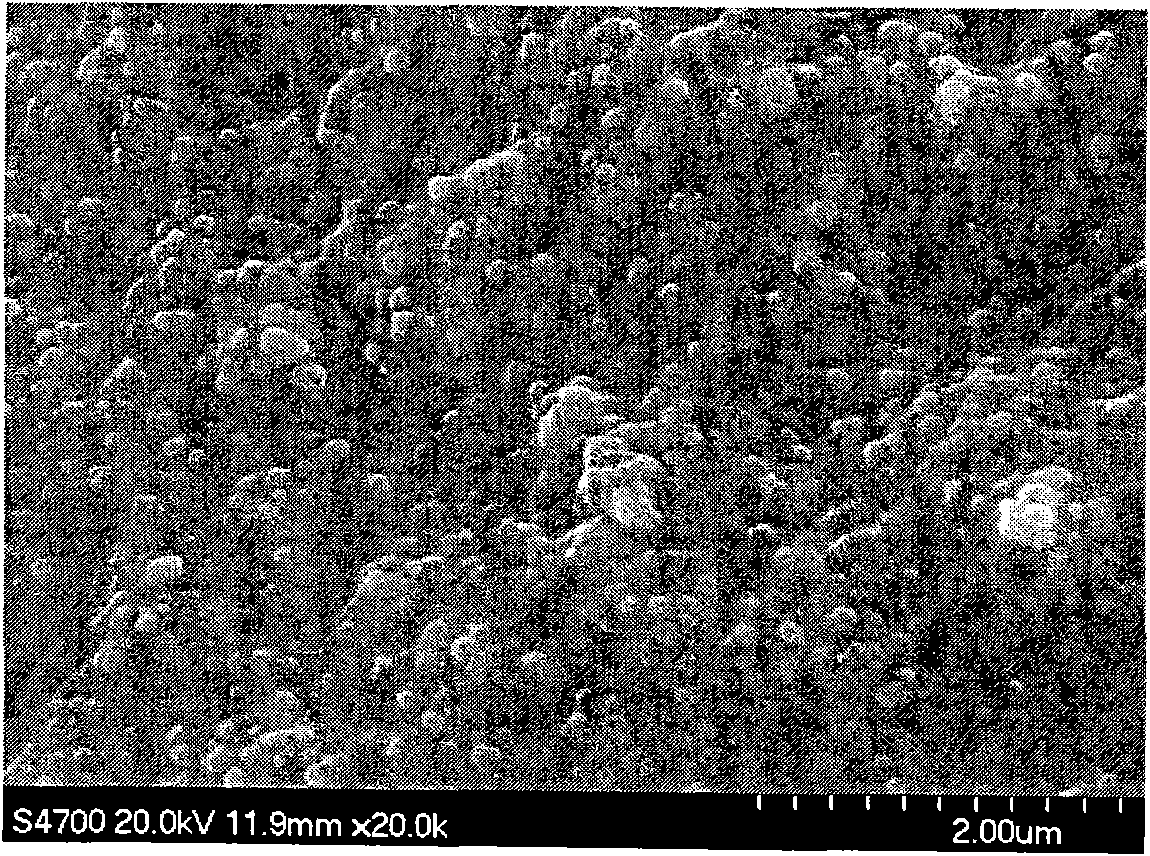

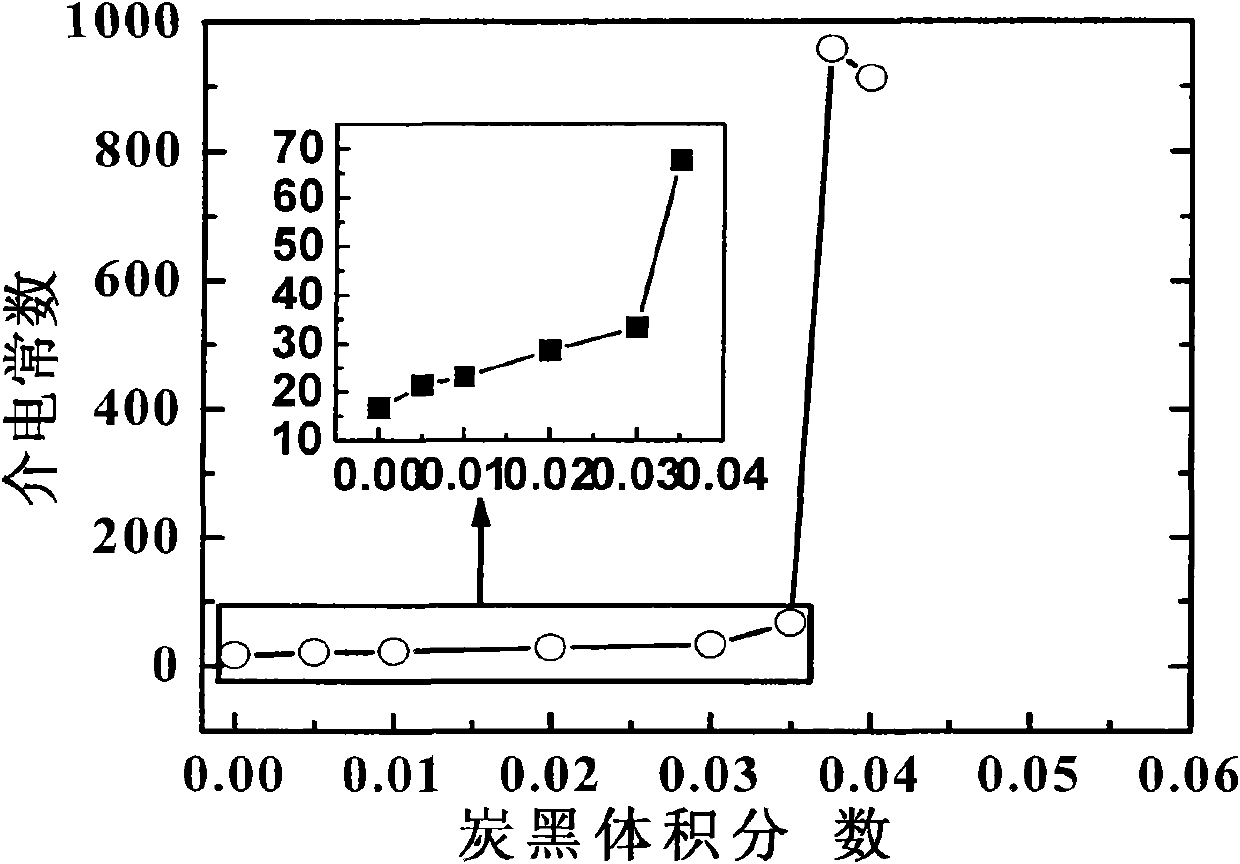

Triphase-body nanometer composite material with high dielectric constant and high elasticity and preparation method thereof

InactiveCN102199356AIncrease elasticityLow dielectric lossRubber insulatorsVulcanizationDielectric loss

The invention discloses a triphase-body nanometer composite material with high dielectric constant and high elasticity and a preparation method thereof, wherein the triphase-body nanometer composite material comprises an inorganic material and an organic material, wherein the inorganic material comprises conductive stuffing carbon black (CB) powder and barium titanate BaTiO3 (BT) and the organic material comprises methylvinylsiloxane rubber (VMQ). The triphase-body nanometer composite material has the formula in a volume ratio: 0.5 to 4% of CB powder body, 40% of barium titanate powder body (BT) and 56 to 59.5% of methylvinylsiloxane rubber (VMQ). The preparation method comprises the steps of: heat-treating the BT powder and the CB powder, grinding and formulating a VMQ solution, carrying out pressure moulding by adopting a solution mixing and low-temperature hot pressing vulcanization method, and carrying out post treatment. The triphase-body (CB / BaTiO3 / VMQ) nanometer composite material disclosed by the invention has the advantages of high dielectric constant, low dielectric loss and high elasticity; and a hot pressing method for reducing forming temperature, shortening preparation time and being convenient for forming is adopted; and the composite material with stable performance and fine tenacity is obtained in a shorter time, therefore time and energy are saved.

Owner:BEIJING UNIV OF CHEM TECH

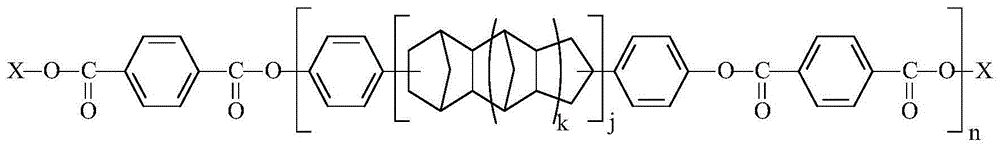

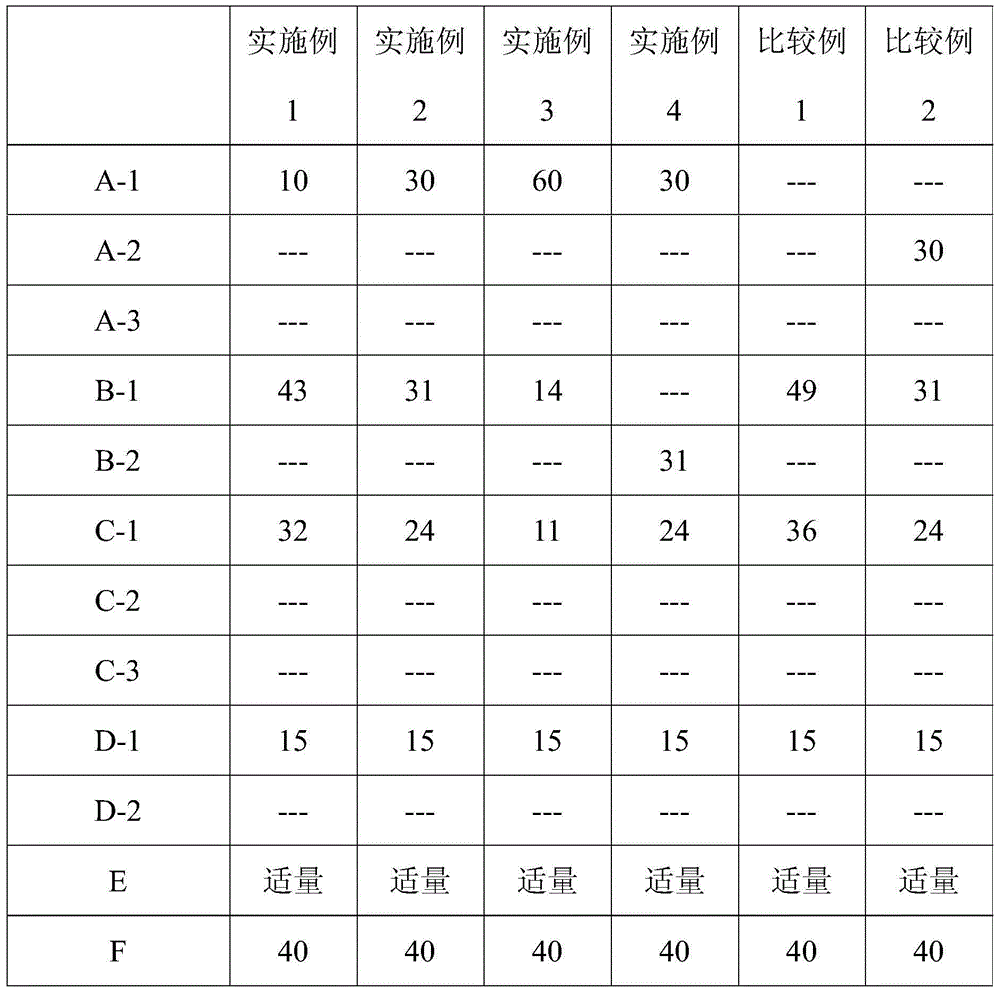

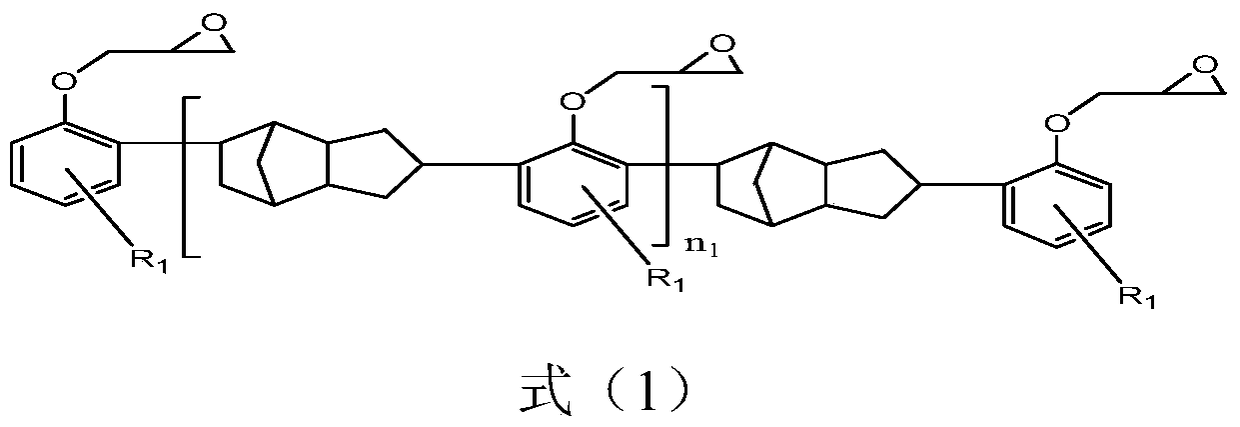

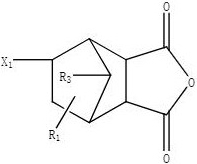

Halogen-free resin composition and application thereof

ActiveCN104974520AImprove water absorptionGood dimensional stabilitySynthetic resin layered productsElectrical equipmentEpoxyDielectric loss

Disclosed is a halogen-free resin composition. The halogen-free resin composition comprises: (A) 10-60 parts by weight of dicyclopentadiene benzoxazine resin; (B) an epoxy resin; (C) an active ester curing agent; and (D) a phosphorus-containing flame retardant, based on 100 parts by weight of the total amount of organic solids of (A), (B), (C) and (D). A prepreg and a laminate that are manufactured from the halogen-free resin composition have low dielectric constant, low dielectric loss, low water absorption rate, high dimensional stability, and excellent heat resistance, fire resistance, processability and chemical resistance.

Owner:GUANGDONG SHENGYI SCI TECH

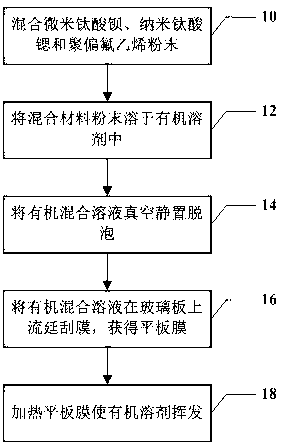

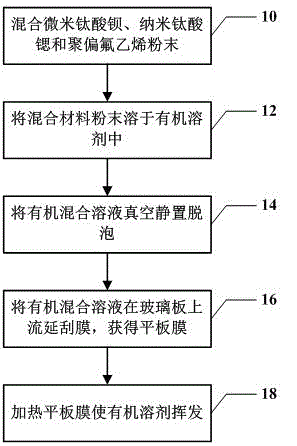

Method for manufacturing high dielectric composite thin film

InactiveCN103319736AHigh dielectric constant valueLow dielectric loss valueStrontium titanateComposite film

The embodiment of the invention discloses a method for manufacturing a high dielectric composite thin film. The method comprises the following steps of: uniformly mixing micron barium titanate, nano strontium titanate and polyvinylidene fluoride powder; dissolving the mixed material powder in an organic solvent; carrying out standing vacuum defoaming on organic mixed solution at the room temperature; carrying out casting knifing on the organic mixed solution on a substrate to form a flat plate film; and heating the flat plate film so that the organic solvent is evaporated to obtain a polyvinylidene fluoride-barium titanate-strontium titanate composite thin film. With the adoption of the method of the embodiment of the invention, strontium titanate particles with nano partical sizes can be filled in gaps among barium titanate particles with micron particle sizes, the barium titanate particles can be stacked more closely, and therefore, a dielectric constant of the obtained composite thin film can be improved greatly and loss can be reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

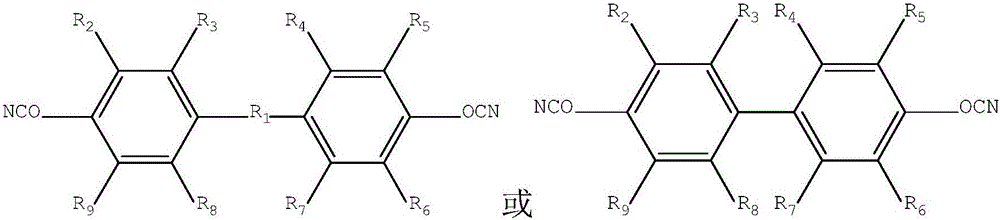

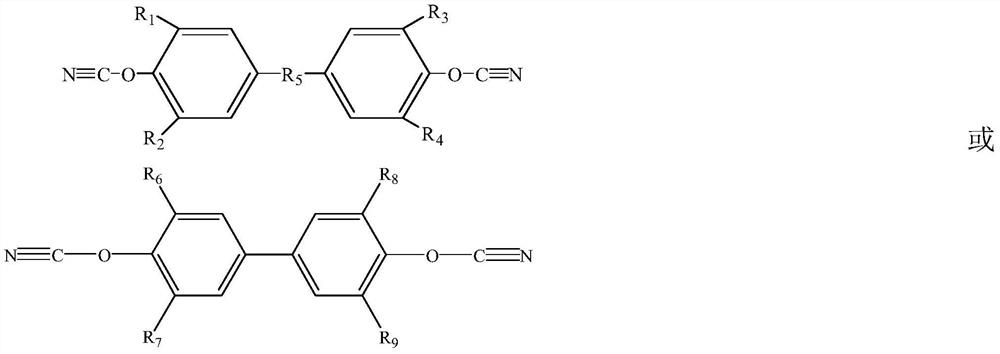

Halogen-free thermosetting resin composition and prepreg and printed circuit laminate employing halogen-free thermosetting resin composition

InactiveCN107177030AHigh TgHigh phosphorus contentSynthetic resin layered productsElectrical equipmentHalogenCyanate compound

The invention relates to a halogen-free thermosetting resin composition and a prepreg and a printed circuit laminate employing the halogen-free thermosetting resin composition. An organic condensate of the halogen-free thermosetting resin composition comprises the ingredients in parts by weight (based on 100 parts): (A) 5-50 parts of cyanate resin; (B) 5-40 parts of polyphenylether resin; (C) 5-30 parts of phosphoric bisphenol polymer; (D) 30-60 parts of halogen-free epoxy resin. The prepreg and the printed circuit laminate made from the halogen-free thermosetting resin composition, provided by the invention, have high glass transition temperature, excellent dielectric properties, low water absorption rate, high heat resistance, high peel strength, excellent humidity resistance and good process processability, can achieve no halogen and flame retardance and reaches UL94 V-0.

Owner:GUANGDONG SHENGYI SCI TECH

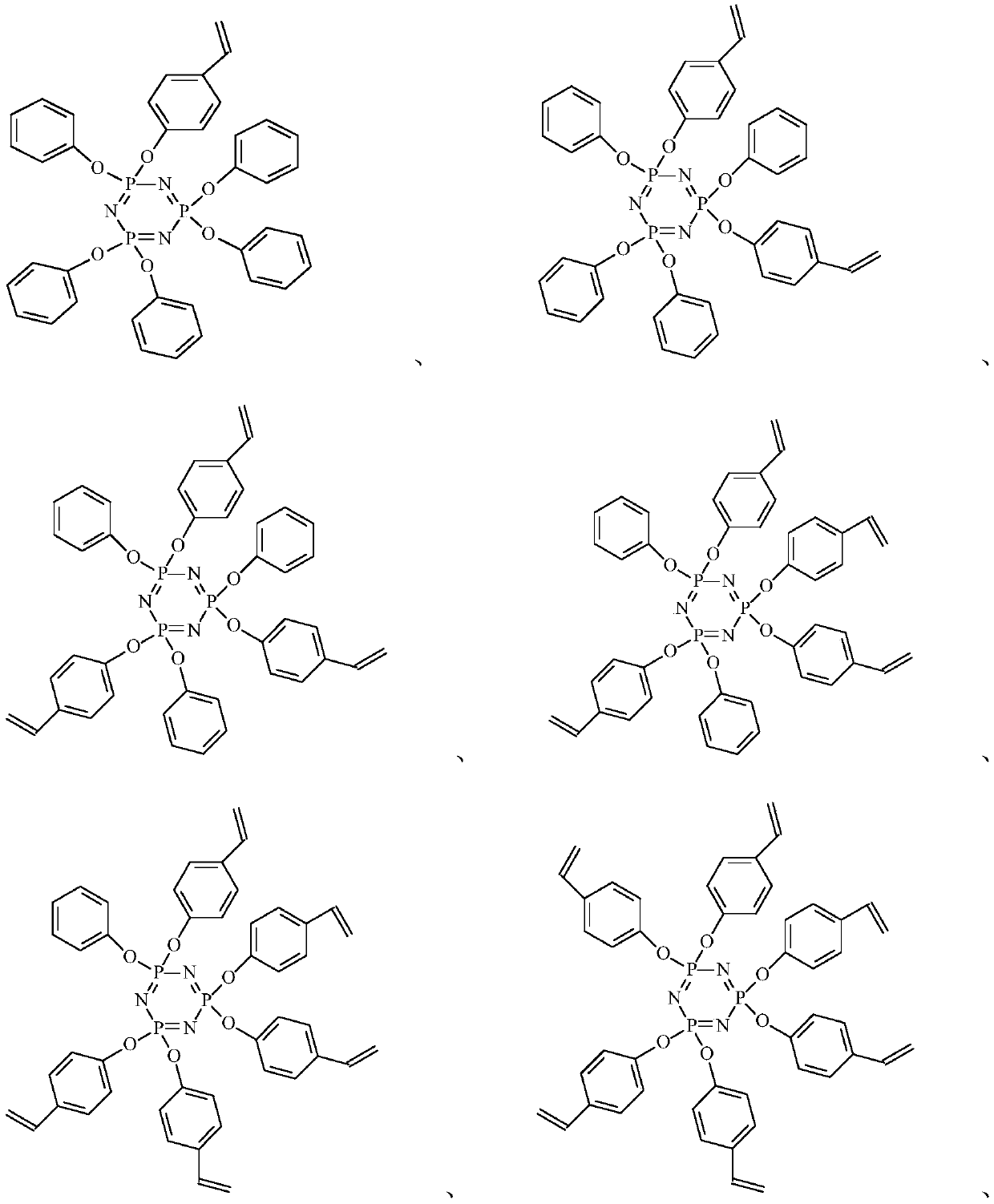

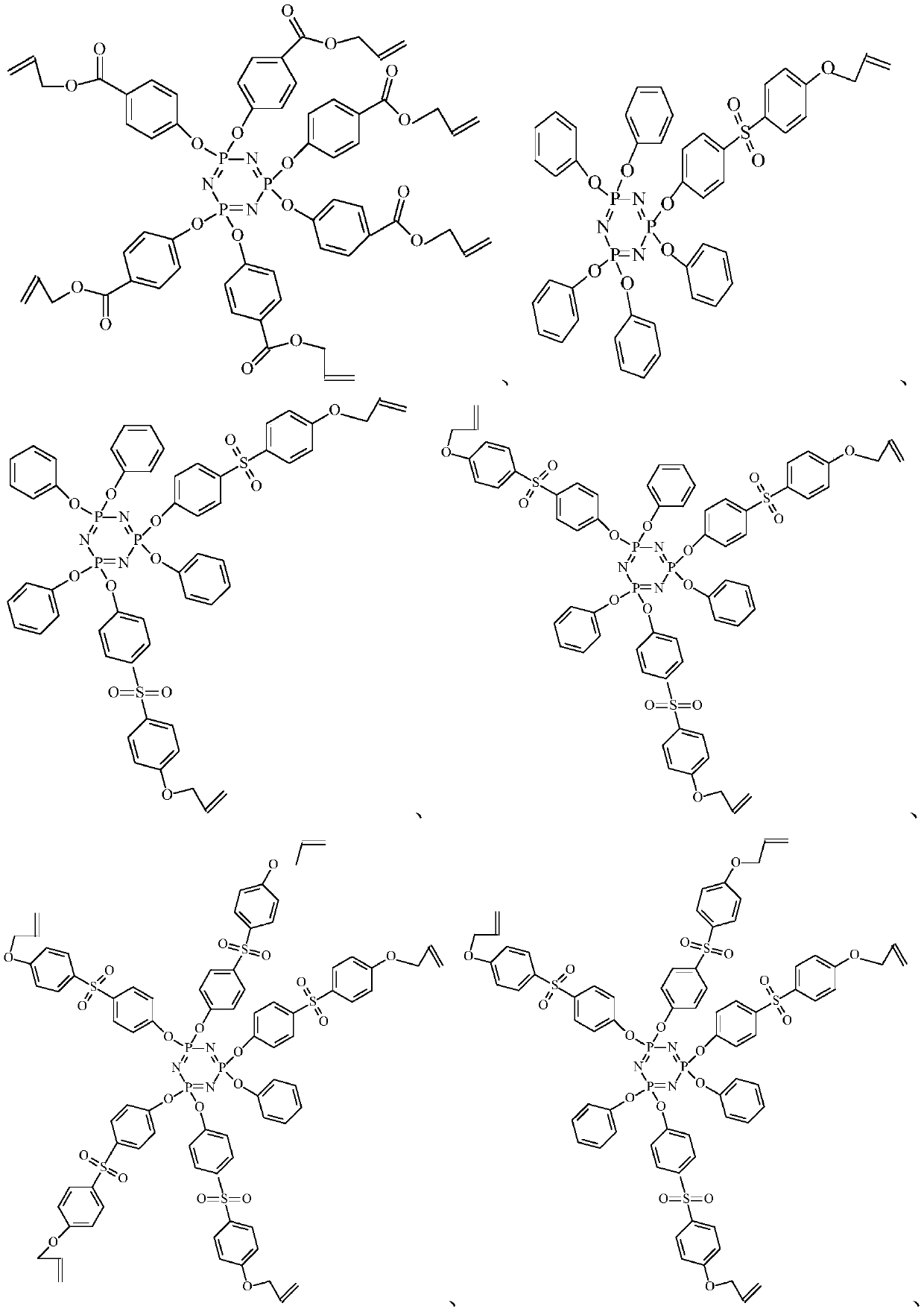

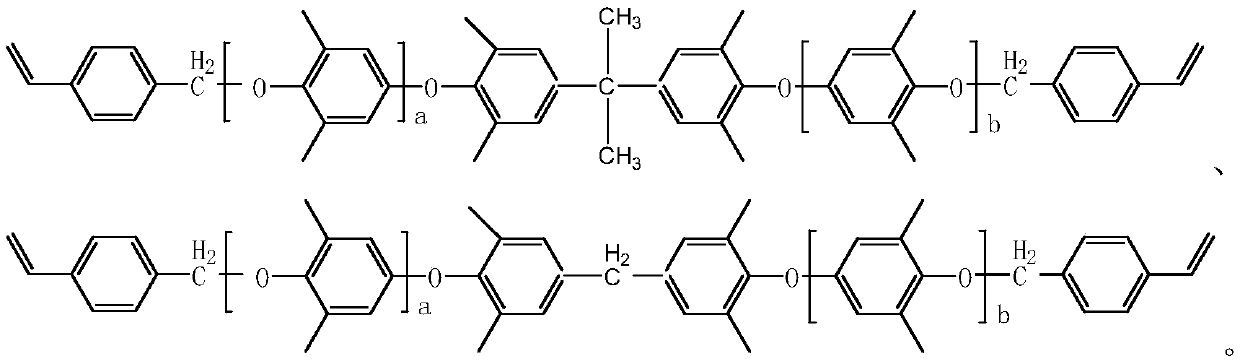

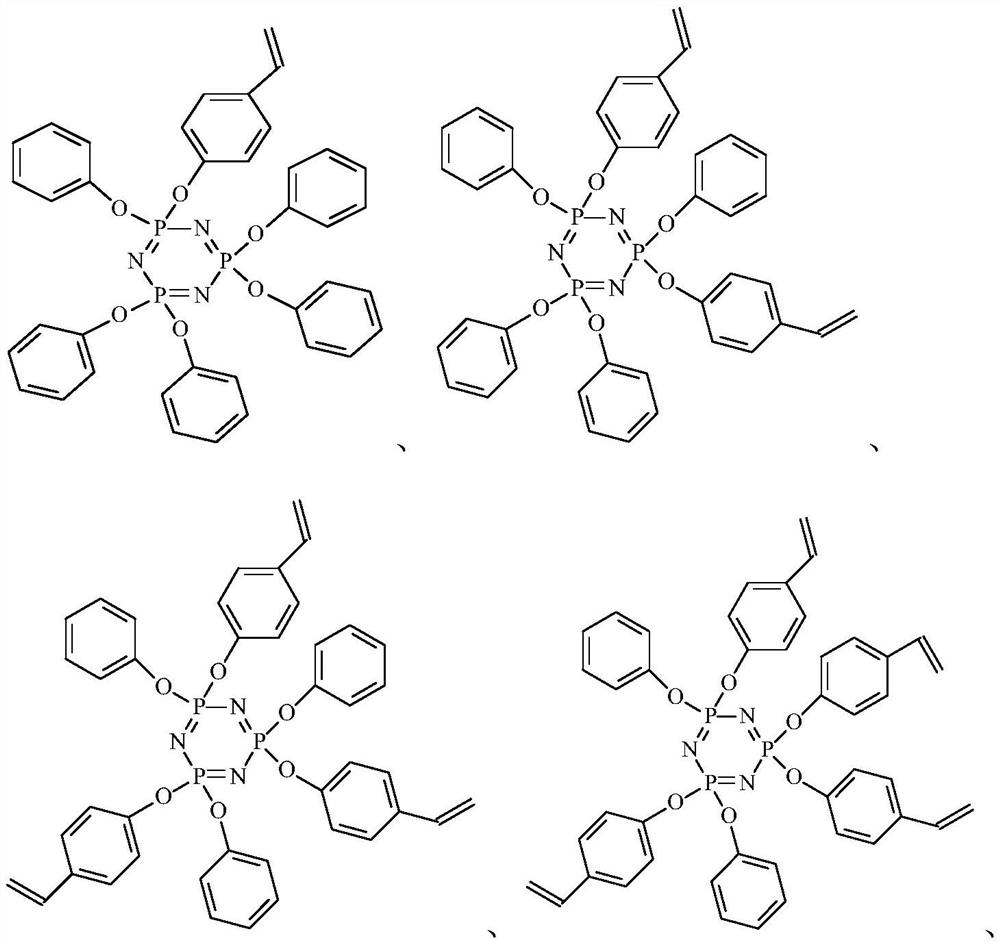

Halogen-free polyphenyl ether resin composition, and prepreg and laminated board prepared from halogen-free polyphenyl ether resin composition

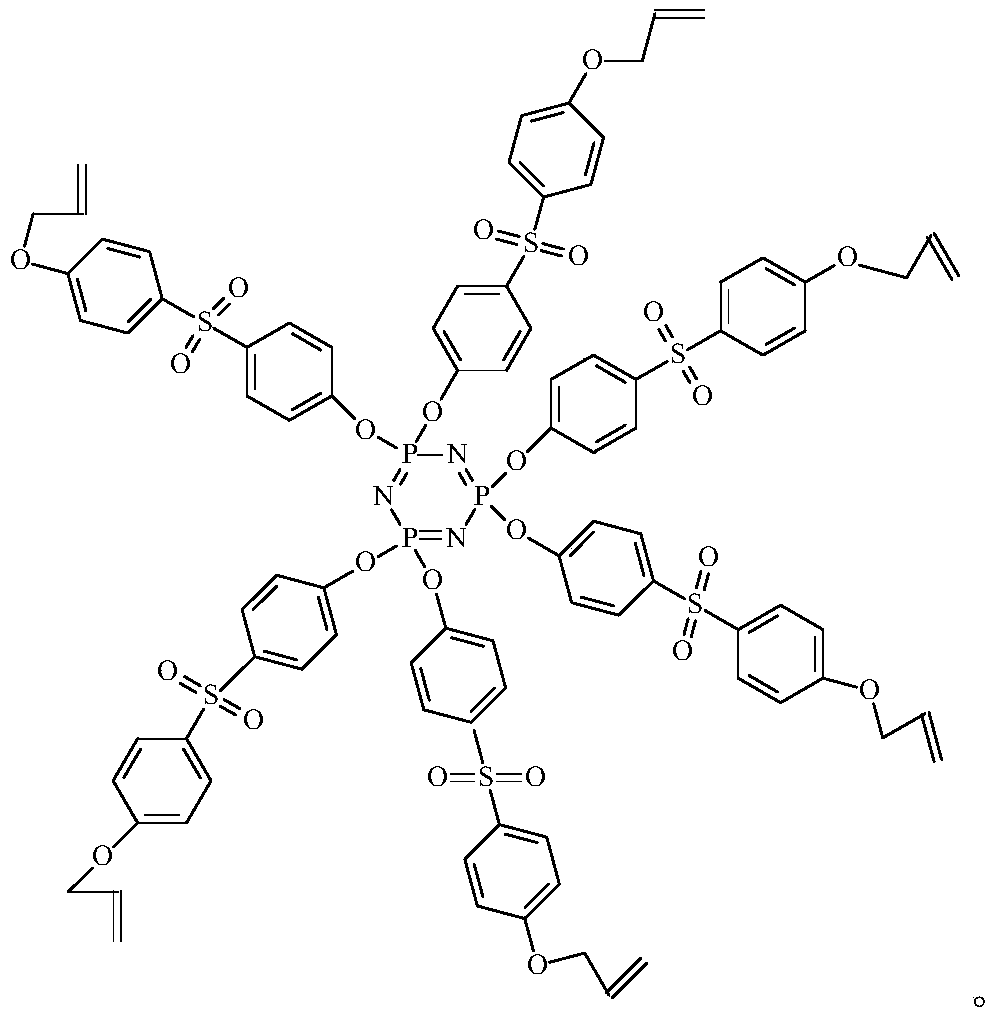

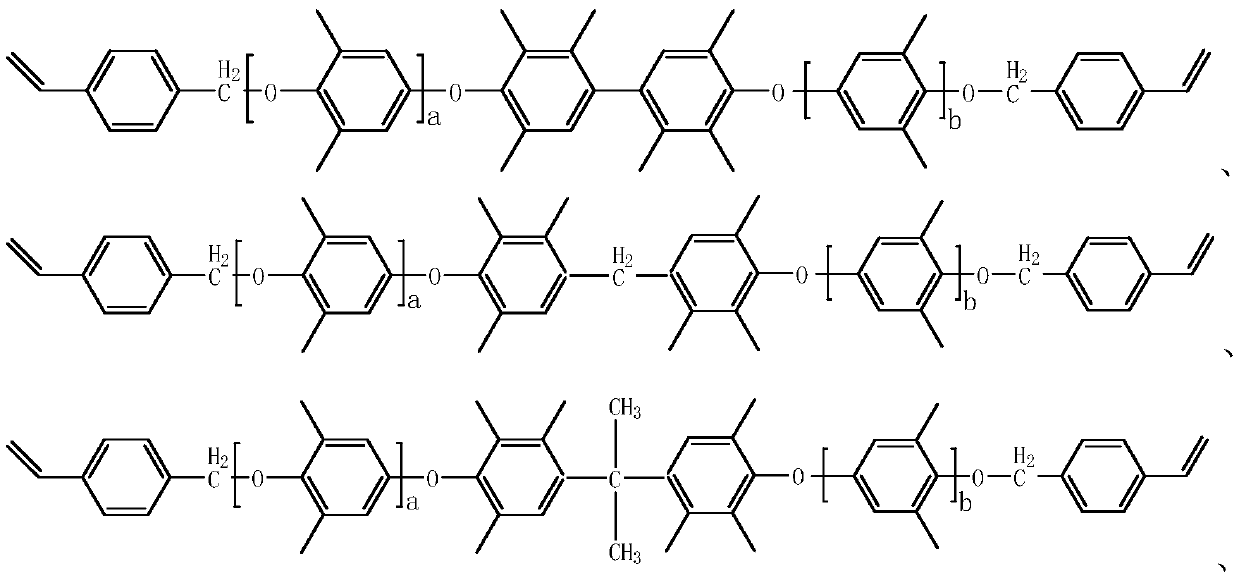

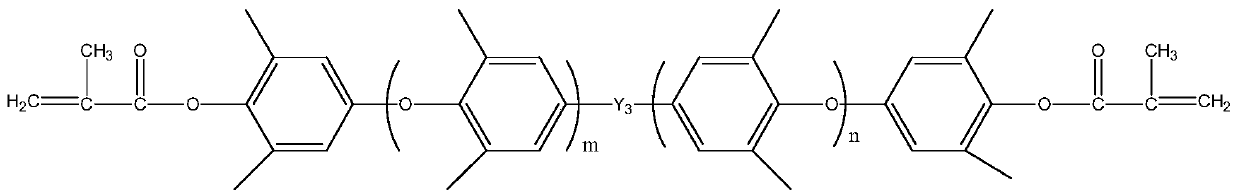

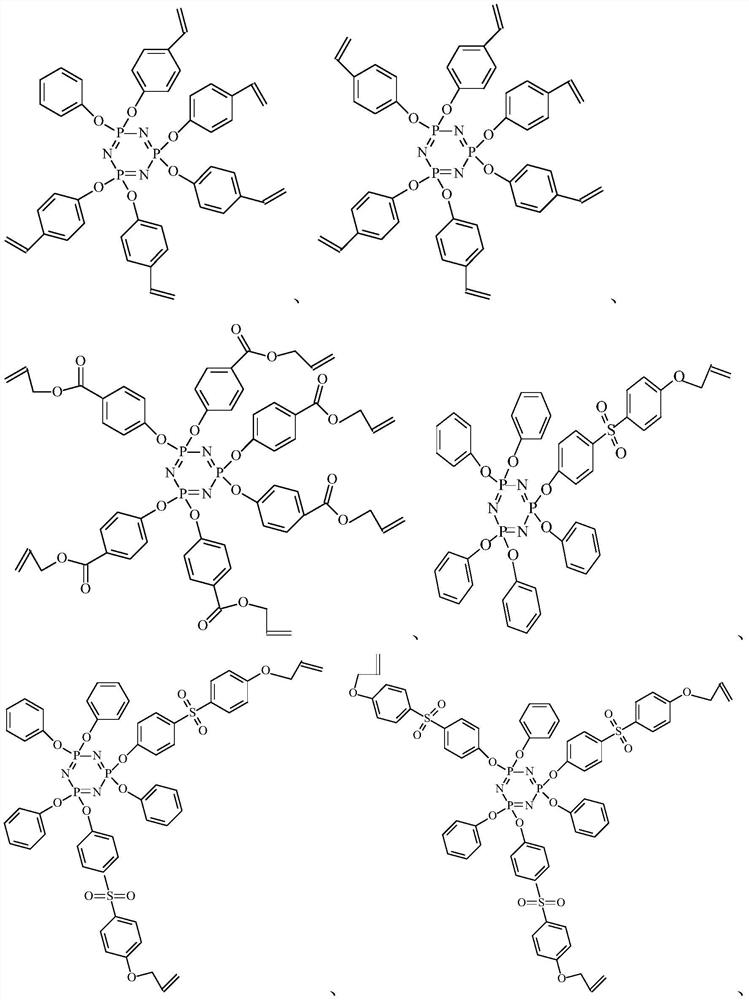

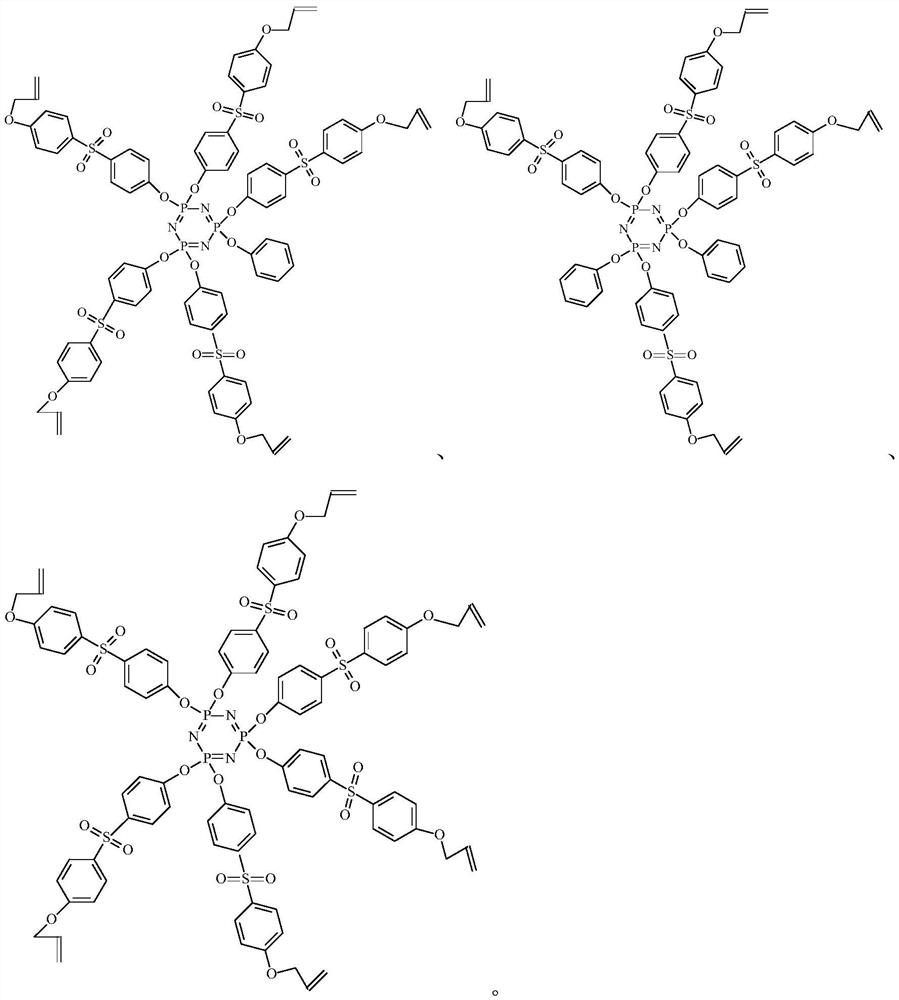

ActiveCN110527037AHomogeneous compatibilityLow dielectric constantSynthetic resin layered productsMetal layered productsCross-linkDielectric loss

The invention discloses a halogen-free polyphenyl ether resin composition. The composition comprises the following components: (a) 100 parts of polyphenyl ether resin containing carbon-carbon unsaturated bonds; (b) 5-60 parts of a phosphorus-containing compound containing carbon-carbon unsaturated bonds; and (c) 0-10 parts of an initiator. According to the invention, the phosphorus-containing compound containing carbon-carbon unsaturated bonds is used as a cross-linking agent for polyphenyl ether and a compound containing carbon-carbon unsaturated bonds, so that the polyphenyl ether and the compound containing carbon-carbon unsaturated bonds can be well and uniformly compounded together, and a lower dielectric constant and a lower dielectric loss value are obtained. Experimental data proves that the resin composition and the laminated board prepared from the resin composition can meet requirements of current 5G products.

Owner:SHENGYI TECH SUZHOU

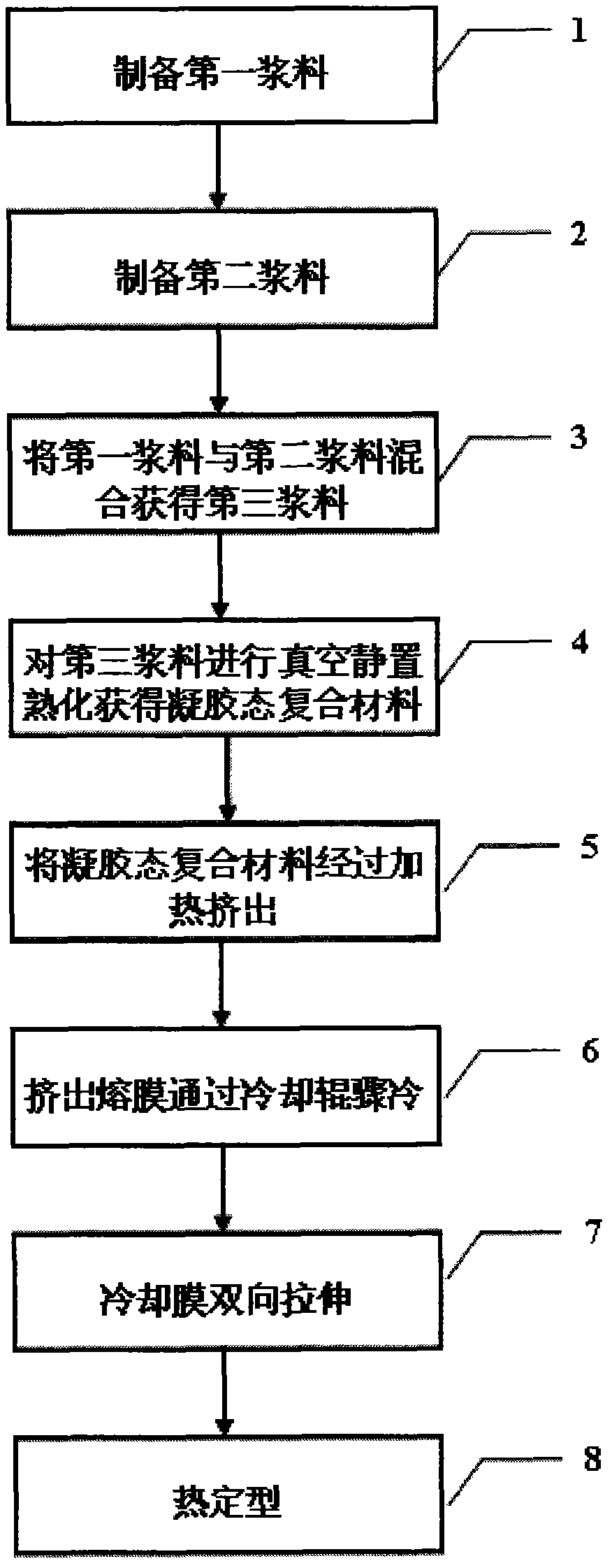

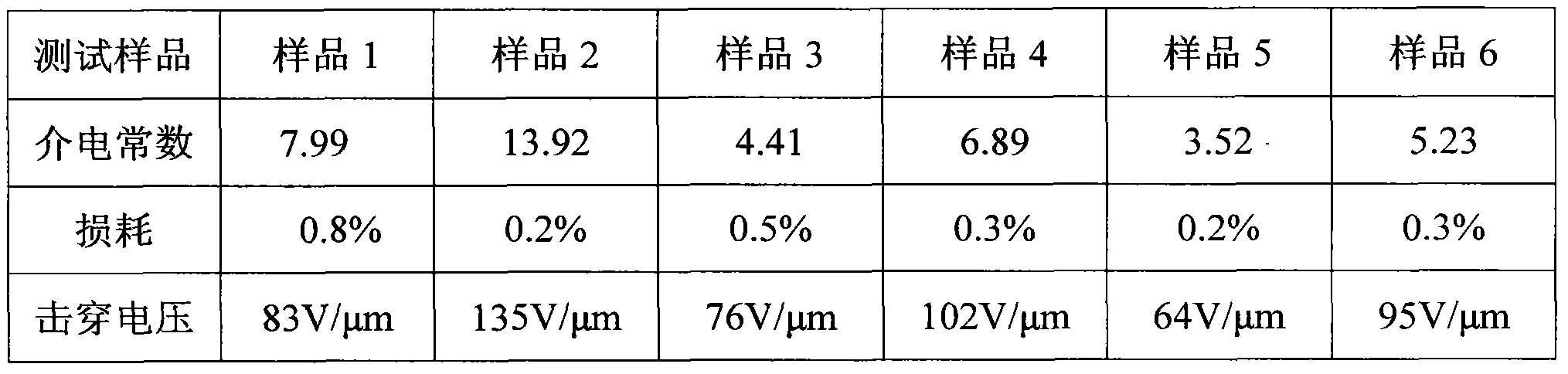

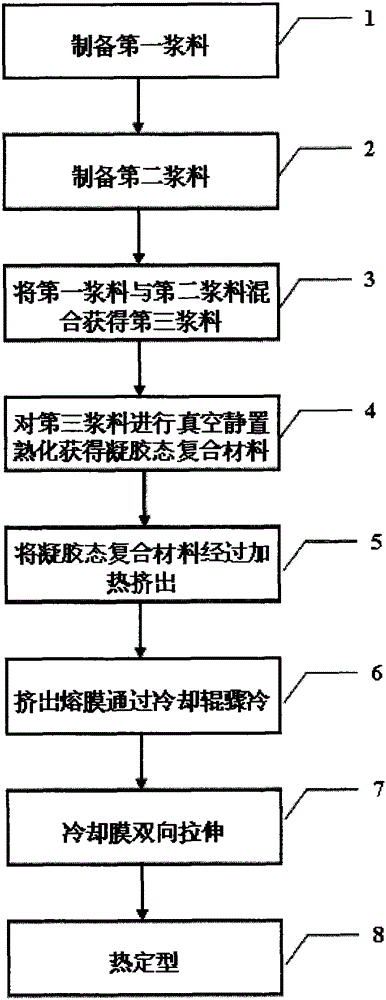

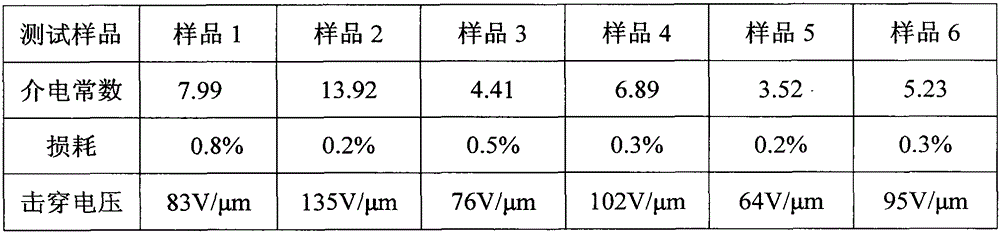

Preparation method of high-dielectric film

The embodiment of the invention discloses a preparation method of a high-dielectric polymer composite film. The preparation method is characterized by comprising the following steps of: sufficiently mixing a main material A and a certain quantity of first solvent to obtain a first slurry; mixing an organic dielectric material B with high dielectric constant and low loss and a certain quantity of second solvent, and dispersing the mixture to obtain a second slurry; sufficiently mixing the first slurry and the second slurry to obtain a third slurry; standing and curing the third slurry in a vacuum container to obtain a uniformly-mixed gel-state high-dielectric organic composite; and adding the gel-state high-dielectric organic composite into an extruding machine for heating and extruding, quenching a molten film through a cooling roller after the molten film is extruded, stretching the extruded cooled film in two ways through a film stretch forming machine, and finally, carrying out heat setting at the temperature of 150 DEG C to obtain the high-dielectric polymer composite film. The film has a high dielectric constant value, a high breakdown voltage value and a low dielectric loss value.

Owner:刘江萍

Halogen-free thermosetting resin composition, prepreg comprising same, laminated board and printed circuit board

InactiveCN106751524AEasy to processReduced processing performanceLaminationLamination apparatusHeat resistanceGlass transition

The invention provides a halogen-free thermosetting resin composition, a prepreg comprising the same, a laminated board and a printed circuit board. The halogen-free thermosetting resin composition comprises the following substances serving as necessary components, in 100 parts of organic solid matters by weight: (A) 35-65 parts of halogen-free epoxy resin; (B) 10-35 parts of poly-phosphonate; (C) 10-30 parts of cyanate ester. The halogen-free thermosetting resin composition, the prepreg comprising the same, the laminated board and the printed circuit board have high glass transition temperature, excellent dielectric property, high peeling strength, high heat resistance, low water absorption and good process machinability, can realize halogen-free flame resistance and reach UL94 V-0.

Owner:GUANGDONG SHENGYI SCI TECH

Halogen-free thermosetting resin composition and prepreg, laminated board, coated metal foil laminated board and printed circuit board using it

ActiveCN108047647AHigh phosphorus contentLow water absorptionFibre treatmentSynthetic resin layered productsMetal foilGlass transition

The invention relates to a halogen-free thermosetting resin composition and a prepreg, a laminated board, a coated metal foil laminated board and a printed circuit board using it. According to 100 parts by weight of organic solid matter, the halogen-free thermosetting resin composition is prepared from, by weight, (A) 25-55 parts of phosphorus containing epoxy resin, (B), 10-40 parts of active ester curing agent, (C), and 20-50 parts of bisphenol fluorine benzoxazine resin. The laminated board prepared by the halogen-free thermosetting resin composition is featured by high glass-transition temperature, low dielectric loss factor, high heat resistance, low water absorption, and good fire resistance, processing performance, and chemical resistance.

Owner:GUANGDONG SHENGYI SCI TECH

Epoxy resin composition and prepreg and laminated board using same

ActiveCN105778412AEasy to detectHigh glass transition temperatureSynthetic resin layered productsRubber layered productsVitrificationDielectric loss

The invention relates to an epoxy resin composition and a prepreg and laminated board using same.The epoxy resin composition is prepared from novolac epoxy resin, core-shell rubber-toughened epoxy resin or / and core-shell rubber, bromized bisphenol A epoxy resin, four-functional-group epoxy resin, active ester and a linear phenolic resin compound curing agent.Adopted novolac epoxy resin has high glass-transition temperature, low water absorption and excellent dielectric property at the same time, core-shell rubber-toughened epoxy resin can improve toughness and technical processablity, bromized bisphenol A epoxy resin provides flame retardance while raising glass-transition temperature, and the active ester and the linear phenolic resin compound curing agent are beneficial for realizing balance among heat resistance, dielectric property and water absorption and reducing cost at the same time.The prepreg and laminated board made of the epoxy resin composition are high in heat resistance, small in dielectric loss value, high in humidity resistance, low in water absorption and good in toughness.

Owner:GUANGDONG SHENGYI SCI TECH

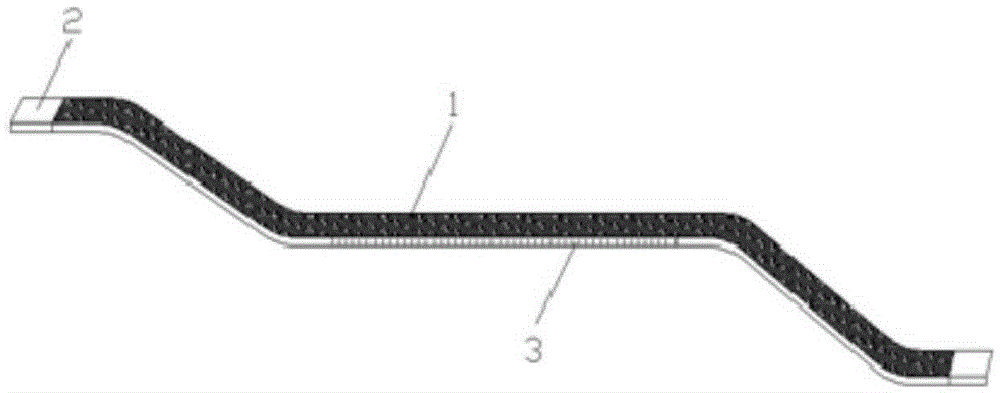

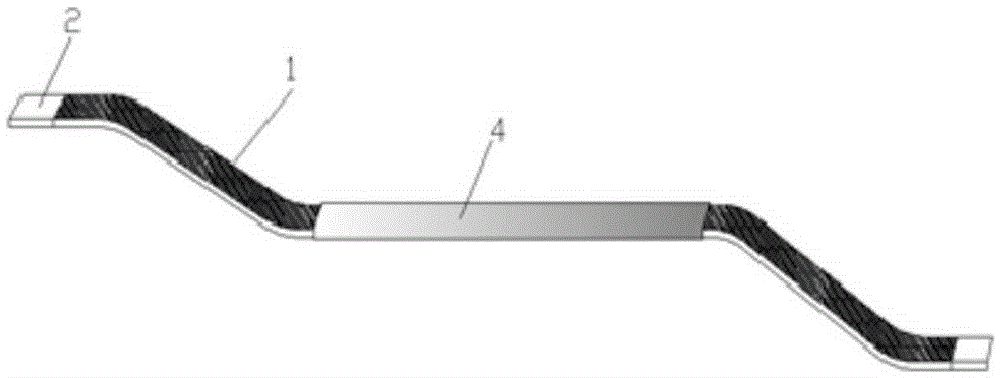

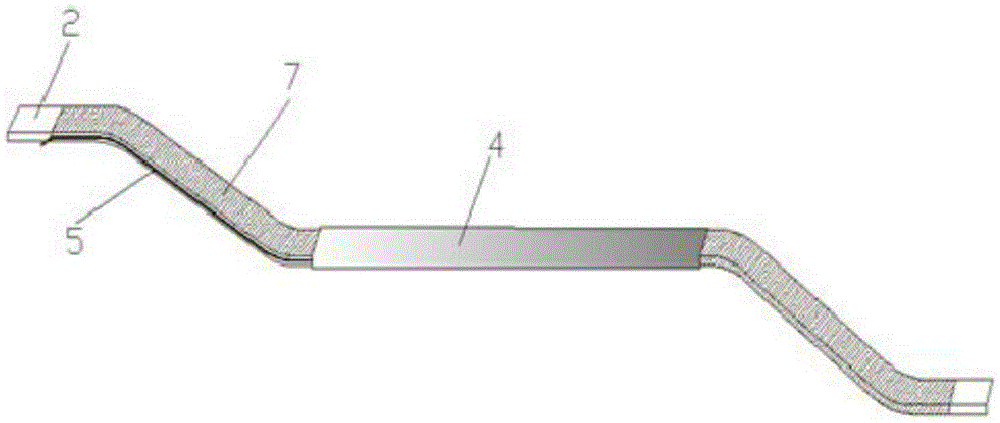

Resistance measurement method for shielding layer of hydrogenerator stator bar

ActiveCN105429375ALow dielectric loss valueSolve the unmeasurableResistance/reactance/impedenceManufacturing dynamo-electric machinesDielectric lossCopper

The invention provides a resistance measurement method for a shielding layer of a large hydrogenerator stator bar. The resistance of the shielding layer of the processed and molded stator bar can be measured by a lead-out copper bar; and the dielectric loss value of the stator bar can be reduced after the lead-out copper bar is connected with a stator bar outgoing line.

Owner:HARBIN ELECTRIC MASCH CO LTD

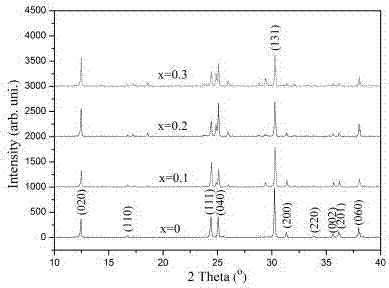

Terahertz waveband medium material, preparation method and method of preparing dielectric medium therefrom

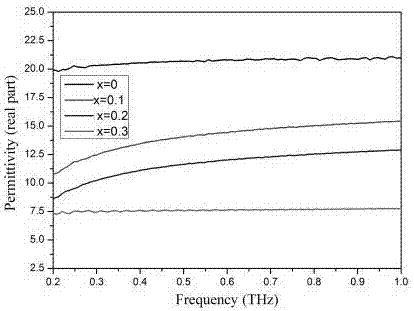

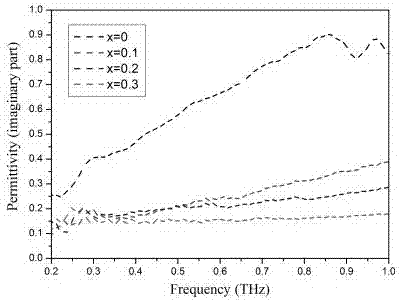

InactiveCN107879738AControl the sintering temperatureRegulate sintered densityDielectric lossNanotechnology

The invention discloses a terahertz waveband medium material, a preparation method and a method of preparing a dielectric medium therefrom. The chemical formula of the medium material is [(Mg<1 x>Al<2 / 3x>)<1 / 3>Nb<2 / 3>]O<2> + y wt% ABSMV, 0<=x<=0.3, and y=1 or 2. The medium material has the advantages of low sintering temperature, low dielectric loss, and moderate dielectric constant.

Owner:LIUPANSHUI NORMAL UNIV

Halogen-free polyphenyl ether resin composition, and prepreg and laminated board prepared therefrom

ActiveCN110615876AHomogeneous compatibilityLow dielectric constantSynthetic resin layered productsElectrical equipmentCross-linkDielectric loss

The invention discloses a halogen-free polyphenyl ether resin composition, which comprises the following components: (a) 100 parts of polyphenyl ether resin containing carbon-carbon unsaturated bonds;(b) 5-60 parts of a phosphorus-containing compound containing carbon-carbon unsaturated bonds; and (c) 0-10 parts of an initiator. According to the invention, the phosphorus-containing compound containing carbon-carbon unsaturated bonds is used as a cross-linking agent for polyphenyl ether and the compound containing carbon-carbon unsaturated bonds; according to the resin composition and the laminated board prepared from the resin composition, polyphenyl ether and a compound containing carbon-carbon unsaturated bonds can be well and uniformly compatible together, a lower dielectric constant and a lower dielectric loss value are obtained, and experimental data prove that the resin composition and the laminated board prepared from the resin composition can meet the requirements of current 5G products.

Owner:SHENGYI TECH SUZHOU

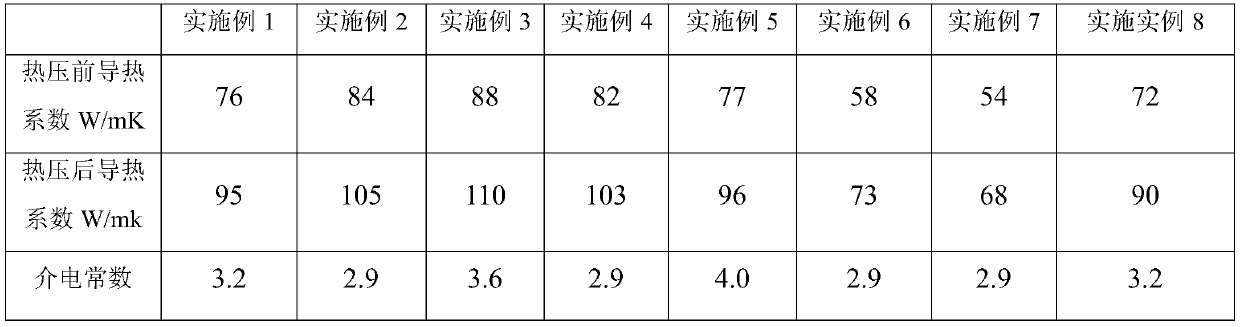

5G antenna flexible insulation cooling fin and preparation process thereof

PendingCN111303626ALow dielectric loss valueHigh dielectric loss valueHeat-exchange elementsDe-icing/drying-out arrangementsDielectric lossEngineering

The invention provides a 5G antenna flexible insulation cooling fin, which comprises 60% of a component A, 39%-39.8% of a component B and 0.2%-1% of a dispersing agent A, wherein the component A comprises the following raw materials: 30%-80% of high-thermal-conductivity insulating powder, 0.2%-1% of a dispersing agent B and 20%-70% of a solvent A, and the component B comprises the following raw materials: 30%-60% of a resin and 40%-70% of a solvent B. According to the invention, the component A, the component B and the dispersing agent A are mixed to prepare the cooling fin, the resin with lowdielectric loss is adopted, the dielectric loss is small, the advantages of being soft and bendable are achieved after resin film forming, and the added high-thermal-conductivity insulating powder can meet the high heat dissipation requirement in 5G antenna application. The invention further provides a preparation process of the 5G antenna flexible insulation cooling fin. According to the invention, the preparation process of the cooling fin is simple and easy to operate, and the prepared cooling fin has the characteristics of low dielectric loss value, softness, excellent heat dissipation performance and the like, and meets the requirements of antenna material products in the 5G electronic industry.

Owner:厦门海洋南方特种光电材料有限公司

An epoxy resin composition and prepregs and laminates using the same

ActiveCN105778430BImprove heat resistance deficiencyExcellent dielectric propertiesSynthetic resin layered productsCircuit susbtrate materialsEpoxyImide

Owner:GUANGDONG SHENGYI SCI TECH

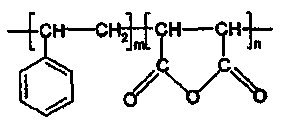

A kind of halogen-free high-frequency resin composition

ActiveCN103554834BImprove heat resistanceEasy to processSynthetic resin layered productsEpoxyCopolymer

The invention discloses a halogen-free high frequency resin composition. The halogen-free high frequency resin composition comprises, by weight, 20-50 parts of a dicyclopentadiene type epoxy resin, 10-40 parts of a styrene-maleic anhydride copolymer, 10-30 parts of a benzooxazine resin, 5-20 parts of a multifunctional epoxy resin and 20-40 parts of at least one phosphorus-containing fire retardant. A copper-clad plate made by using the halogen-free high frequency resin composition has the characteristics of low dielectric constant, low dielectric loss, high heat resistance, low hygroscopic coefficient, low expansion coefficient, good PCB processability and the like.

Owner:ITEQ DONGGUAN

A kind of halogen-free polyphenylene ether resin composition and prepreg and laminate made by using it

ActiveCN110527037BHomogeneous compatibilityLow dielectric constantSynthetic resin layered productsMetal layered productsPolymer scienceEther

The invention discloses a halogen-free polyphenylene ether resin composition, which comprises the following components: (a) polyphenylene ether resin containing carbon-carbon unsaturated bonds: 100 parts; (b) phosphorus-containing resin containing carbon-carbon unsaturated bonds Compound: 5~60 parts; (c) Initiator: 0~10 parts. In the present invention, the phosphorus-containing compound containing carbon-carbon unsaturated bonds acts as a crosslinking agent between polyphenylene ether and carbon-containing unsaturated bond compounds, and can well uniformly polyphenylene ether and carbon-carbon unsaturated bond-containing compounds. Compatible together, a lower dielectric constant and a lower dielectric loss value are obtained. Experimental data proves that the resin composition of the present invention and the laminate prepared therefrom can meet the requirements of current 5G products.

Owner:SHENGYI TECH SUZHOU

A kind of method for preparing high dielectric film

Owner:成都斯托瑞科技有限公司

A kind of halogen-free thermosetting resin composition, prepreg, laminate and printed circuit board using it

ActiveCN110885428BImprove heat resistanceLow dielectric loss valueElectrical equipmentGlass/slag layered productsPolymer sciencePhosphoric acid

The invention provides a halogen-free thermosetting resin composition, a prepreg, a laminate, and a printed circuit board using the same. The halogen-free thermosetting resin composition includes a halogen-free epoxy resin and a curing agent, and the curing agent includes The cyanate resin and the phosphoric anhydride-containing resin have the following components: 5-50 parts of cyanate resin, 30-60 parts of halogen-free epoxy resin and 15-40 parts of phosphoric anhydride-containing resin. In the present invention, cyanate ester and phosphoric anhydride are jointly used as the curing agent of halogen-free epoxy resin, and the two act synergistically to enhance the high heat resistance of the composition and have low dielectric loss value, and the three resins are mixed and cured, and the common The effect also brings the system to have excellent anti-peel strength and interlayer adhesion as well as excellent flame retardancy.

Owner:GUANGDONG SHENGYI SCI TECH

An epoxy resin composition and prepregs and laminates using the same

ActiveCN105778412BHigh glass transition temperatureLow water absorptionSynthetic resin layered productsRubber layered productsHeat resistanceDielectric loss

Provided are an epoxy resin composition as well as a prepreg and a laminated plate using same. The epoxy resin composition comprises: phenol formaldehyde epoxy resin; core-shell rubber toughened epoxy resin and / or core-shell rubber; bromide bisphenol A-type epoxy resin: tetrafunctional epoxy resin: active ester and linear phenol formaldehyde resin composite curing agent. The prepreg and the laminated plate formed by using the epoxy resin composition have good thermal resistance, low dielectric loss, good humidity resistance, low water absorption and good toughness.

Owner:GUANGDONG SHENGYI SCI TECH

Bimaleimide foam material and preparation thereof

InactiveCN101343413BImprove heat resistanceExcellent dielectric propertiesDiphenylmethanePolymer science

The invention discloses bismaleimide foaming material and the preparation method. The bismaleimide foaming material is composed of 100 parts of N, N`-4, 4`-diphenylmethane bismaleimide / O, O`-diallyl bisphenol A performed polymer and 3 to 12 parts of foaming agent. The preparing method adopts 100 parts of bismaleimide and 43 parts to 103 parts of diallyl bisphenol A resin to be mixed at the temperature of 120 DEG C to 150 DEG C to obtain the performed polymer, 3 to 12 parts of foaming agent are added into the performed polymer per 100 parts of the performed polymer and are evenly mixed, the mixture is positioned into a preheating die, is foamed at 140 DEG C to 180 DEG C for 35 to 10 min, is solidified at the temperature of 140 to 200 DEG C for 4 hours to 8 hours and then is processed at the temperature of 220 DEG C to 240 DEG C for 4 hours to 10 hours, to obtain the bismaleimide foaming material with high performance. The bismaleimide foaming material can be applied to occasions where the requirements for lightness, heat resistance and dielectric properties and mechanical properties of the material are high and also can be served as core material for forming composite material withhigh performance.

Owner:SUZHOU UNIV

Method for manufacturing high dielectric composite thin film

InactiveCN103319736BHigh dielectric constant valueLow dielectric loss valueStrontium titanateComposite film

The embodiment of the invention discloses a method for manufacturing a high dielectric composite thin film. The method comprises the following steps of: uniformly mixing micron barium titanate, nano strontium titanate and polyvinylidene fluoride powder; dissolving the mixed material powder in an organic solvent; carrying out standing vacuum defoaming on organic mixed solution at the room temperature; carrying out casting knifing on the organic mixed solution on a substrate to form a flat plate film; and heating the flat plate film so that the organic solvent is evaporated to obtain a polyvinylidene fluoride-barium titanate-strontium titanate composite thin film. With the adoption of the method of the embodiment of the invention, strontium titanate particles with nano partical sizes can be filled in gaps among barium titanate particles with micron particle sizes, the barium titanate particles can be stacked more closely, and therefore, a dielectric constant of the obtained composite thin film can be improved greatly and loss can be reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

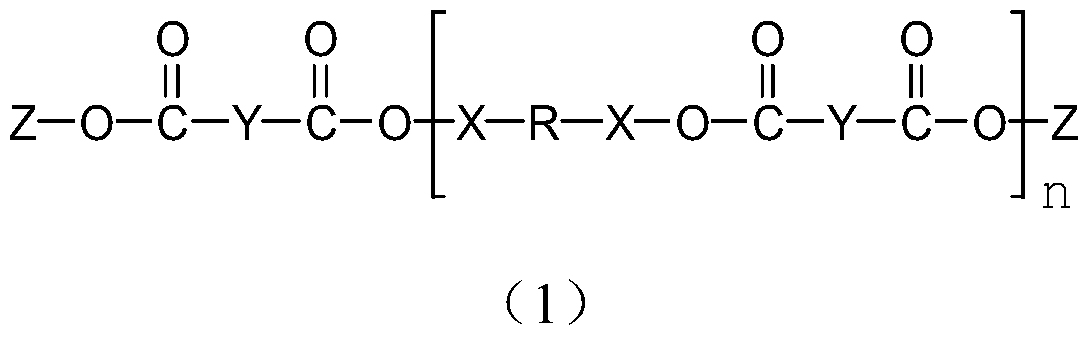

Resin composition and prepreg, laminated board, printed wiring board having same

ActiveCN110643131BLow dielectric constantLow dielectric loss valuePrinted circuit aspectsElectrical equipmentPolymer scienceDielectric loss

The invention provides a resin composition and its prepreg, laminated board and printed circuit board. The resin composition includes: a hydrocarbon resin, a crosslinking aid, and a flame retardant; the hydrocarbon resin contains at least an epoxy-modified hydrocarbon resin; the flame retardant contains at least a phosphorus-containing compound (I) , the phosphorus-containing compound (I) is a phosphoric anhydride-containing compound. The resin composition of the present invention, through the reaction of phosphoric anhydride-containing compounds and epoxy-modified hydrocarbon resins, phosphorus atoms are well introduced into the curing cross-linking system of hydrocarbon resins, so as to meet the requirements of both halogen-free flame retardancy and Substrate material with low dielectric constant and low dielectric loss value.

Owner:常熟生益科技有限公司

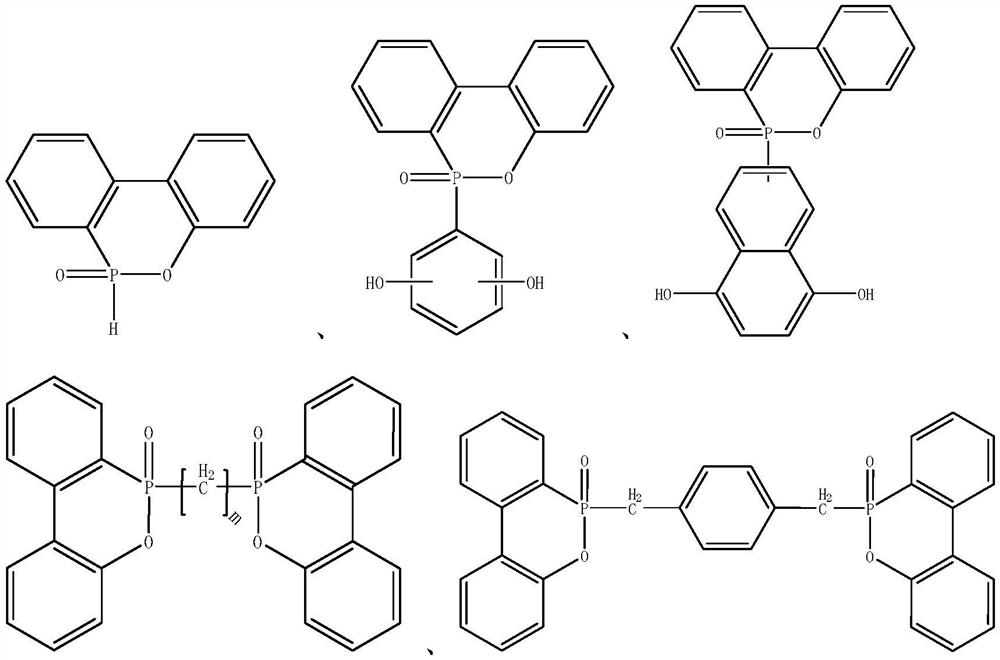

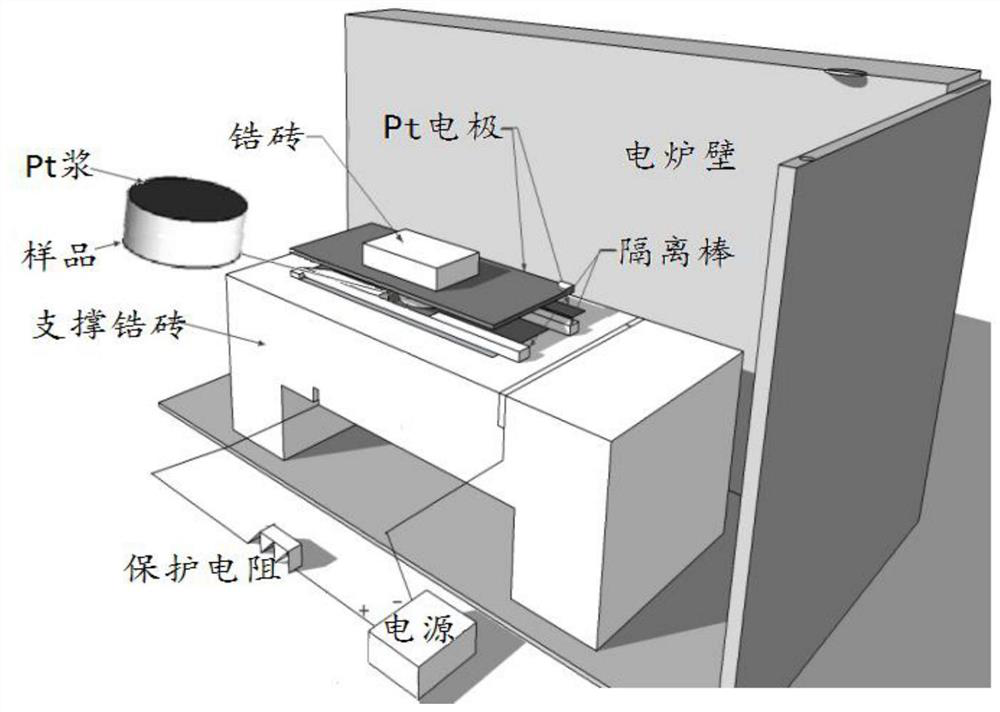

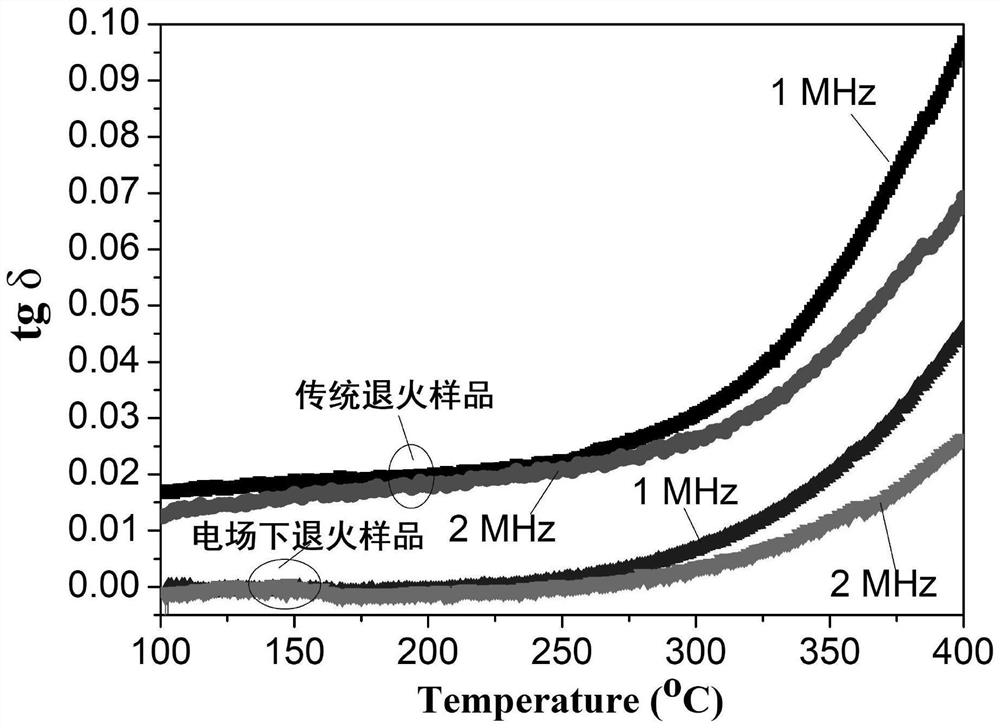

An Electric Field-Induced Method for Ordered Domain Structures in Complex Perovskites

ActiveCN109180222BImprove Q valueLong-range ordered domain structure optimizationGalvano-magnetic material selectionTitaniumAlternating current

The invention discloses a method for inducing an ordered domain structure in a complex perovskite by an electric field. Carry out according to the following steps: a. prepare composite perovskite ceramics according to the conventional process; b. anneal the composite perovskite ceramics prepared in step a, specifically as follows: coat Put Pt slurry on both sides of the composite perovskite ceramics and put Pt wire electrodes on both sides and press them with zircon bricks. After supporting the above composite perovskite ceramics with zircon bricks, lead the Pt wire electrodes out of the electric furnace and connect them to AC power Positive and negative electrodes, then apply an alternating electric field through an AC power supply, and at the same time, anneal the composite perovskite ceramics at a temperature of 700°C to 900°C for 100 to 180 minutes. After the annealing is completed, the desired finished product is obtained. The invention has the advantages of low annealing temperature, short annealing time and obvious improvement of the Q value of ceramics.

Owner:GUIZHOU MINZU UNIV

Zirconium and molybdenum-doped bismuth layer-shaped leadless piezoelectric ceramic material and preparation method thereof

ActiveCN102010195BLow dielectric constantLow dielectric loss valuePiezoelectric/electrostrictive/magnetostrictive devicesElectromechanical coupling coefficientPiezoelectric sensor

The invention relates to a zirconium and molybdenum-doped bismuth layer-shaped leadless piezoelectric ceramic material and a preparation method thereof, belonging to the field of piezoelectric ceramic materials. The novel piezoelectric ceramic material can be prepared by doping Zr and Mo at Ta position in a certain mol ratio according to a preparation method of a solid-phase process, with a SrBi2Ta2O9 system leadless piezoelectric ceramic material as a matrix. The formula of the leadless piezoelectric ceramic material is SrBi2(Zr0.5Mo0.5)xTa2-xO9, wherein x is not less than 0 and not more than 2. On the basis of SrBi2Ta2O9, the material improves the piezoelectric constant and reduces the dielectric constant. Meanwhile, the layer-shaped leadless piezoelectric ceramic material has the advantages of low electromechanical coupling coefficient, high mechanical quality factor and the like, can be used for preparing various piezoelectric ceramic elements, can be assembled into various piezoelectric sensors and has excellent performance.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method for preparing low-temperature cofired dielectric ceramic and material and sintering aid of low-temperature cofired dielectric ceramic

The invention relates to a sintering aid for a low-temperature cofired dielectric ceramic material. The sintering aid comprises the following components in percentage by mass: 40 to 55 percent of silicon dioxide, 5 to 16 percent of boron oxide, 12 to 17 percent of zinc oxide, 5 to 15 percent of aluminum oxide, 3 to 10 percent of lithium oxide, 0 to 5 percent of copper oxide, 0 to 5 percent of cobaltosic oxide and 3 to 8 percent of oxides of which the general formula is R2O3, wherein R may be at least one of lanthanum, neodymium, samarium and dysprosium. By the sintering aid for the low-temperature cofired dielectric ceramic material, the low-temperature cofired dielectric ceramic material can be sintered at temperature of between 830 and 950 DEG C, and the dielectric performance of the low-temperature cofired dielectric ceramic is improved effectively. In addition, the invention also provides the low-temperature cofired dielectric ceramic material and a method for preparing the low-temperature cofired dielectric ceramic.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com