Halogen-free resin composition, prepreg prepared from halogen-free resin composition and laminated board prepared from halogen-free resin composition and used for printed circuit

A resin composition and resin technology, applied in the direction of circuit substrate materials, printed circuit parts, synthetic resin layered products, etc., can solve the problems of ordinary dielectric properties, easy moisture absorption and explosion, and difficulty in meeting the high-speed requirements of printed circuit copper clad laminates. To meet the requirements of globalization development and other issues, to achieve the effects of excellent dielectric properties, lower dielectric constant, and high glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below through specific embodiments.

[0049] The glass transition temperature, dielectric constant, dielectric loss factor, bending strength, water absorption, heat resistance, flame retardancy and other properties of the printed circuit laminate (10 pieces of prepreg) made above were tested, The following examples are further detailed and described.

[0050] The embodiments of the present invention are described in detail as follows, but the present invention is not limited to the scope of the embodiments. There is no special description below, the parts represent parts by weight, and the % represents "% by weight".

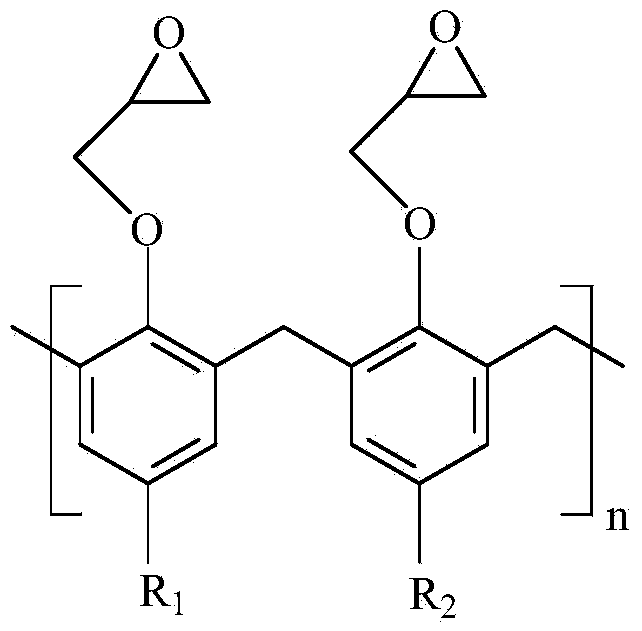

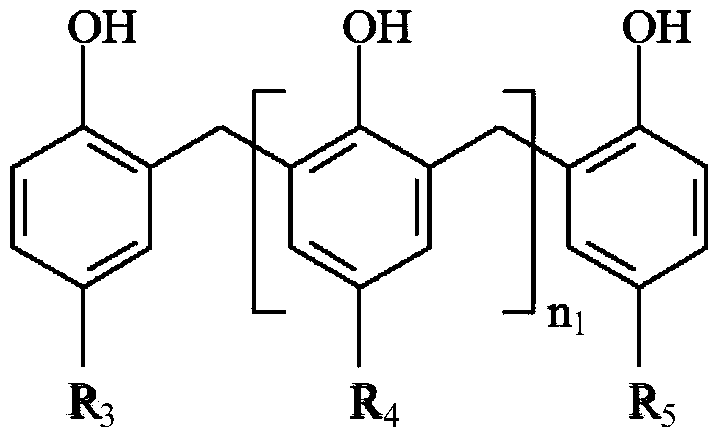

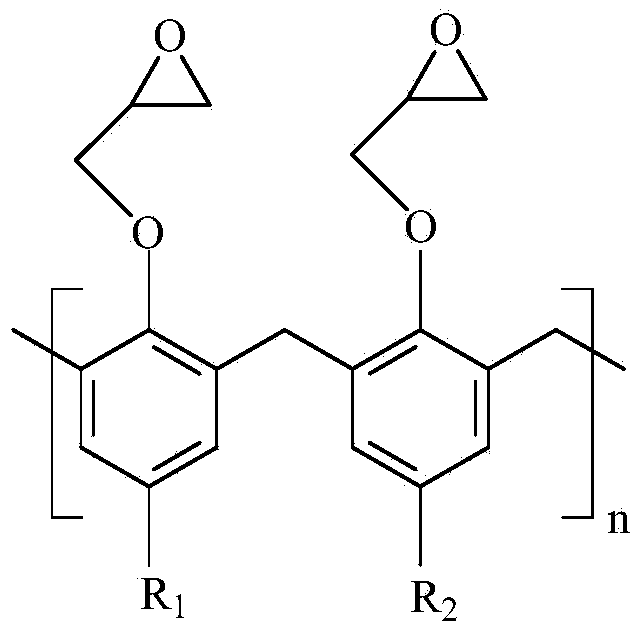

[0051] (A) epoxy resin

[0052] (A-1) Alkylphenol epoxy resin

[0053] KES-7595 (Korea KOLON product name)

[0054] (A-2) Bisphenol A Novolak Epoxy Resin

[0055] EPR627MEK80 (trade name of Hexion in the United States)

[0056] (B) Benzoxazine resin

[0057] LZ8290H62 (HUNTS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com