Triphase-body nanometer composite material with high dielectric constant and high elasticity and preparation method thereof

A nanocomposite, high dielectric constant technology, applied in rubber insulators, organic insulators, etc., can solve the problems of difficult to obtain flexibility, loss of mechanical properties, increase in dielectric loss, etc., to shorten the preparation time, save time and Energy, effect of lowering molding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

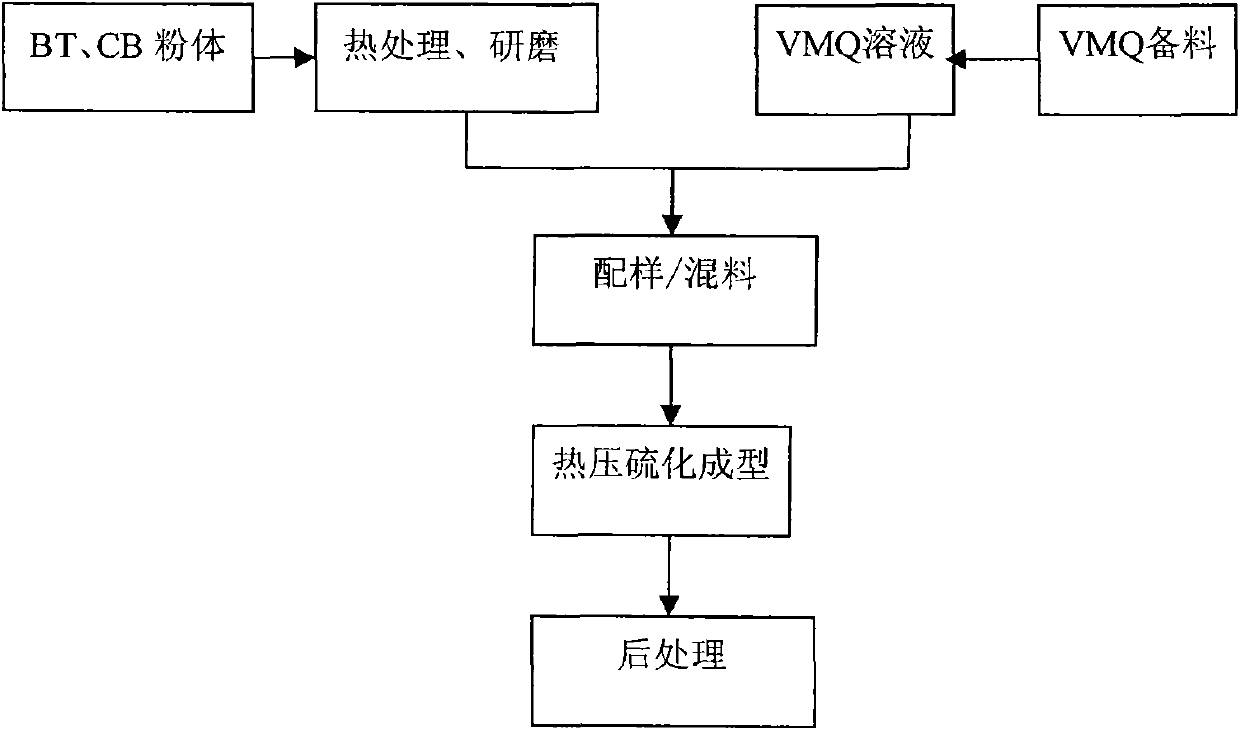

[0031] According to the A1 label formula in table 1, adopt the above-mentioned preparation method to make 13.054g of BaTiO 3 , 3.5569g of VMQ, 0.05673g of CB three materials are fully mixed evenly, after being hot-pressed and vulcanized at 170°C on a hot press (pressure of 15MPa, time of 15min), the second stage is carried out in an oven at 190°C for 3 hours Vulcanization, process such as figure 1 The second half shown. The dielectric constant of its three-phase composite material (CB / BT / VMQ) corresponds to Figure 4 In 2, the dielectric loss corresponds to Figure 5 2 of

Embodiment 2A2-A6

[0033] With CB powder and VMQ by A2-A6 label proportioning and above-mentioned preparation method in table 1, with the BaTiO of 13.054g 3 Mix thoroughly and evenly. After hot press vulcanization at 170°C (pressure 15MPa, time 15min) on a hot press, perform two-stage vulcanization in an oven at 190°C for 3 hours. The process flow is as follows: figure 1 shown. A series of samples can be prepared by using this method, and the dielectric constant of the three-phase composite material whose sample ratio is A2-A6 varies with frequency corresponding to Figure 4 In 3-7, the dielectric loss of the three-phase composite material whose sample ratio is A2-A5 changes with frequency Figure 5 In 3-6, the relationship between the dielectric constant of the three-phase composite material with the sample ratio of A5 and the temperature and frequency corresponds to Image 6 . The elastic moduli of the three-phase composites with sample ratios of A4 and A5 correspond to Figure 7 2 and 3 i...

Embodiment 3A7

[0035] CB powder and VMQ are pressed the A7 proportioning in table 1 with the BaTiO of 13.054g 3 Mix thoroughly and evenly. After hot press vulcanization at 170°C (pressure 15MPa, time 15min) on a hot press, perform two-stage vulcanization in an oven at 190°C for 3 hours. The process flow is as follows:figure 1 shown. The frequency-dependent dielectric properties of the sample correspond to Figure 4 8 of them.

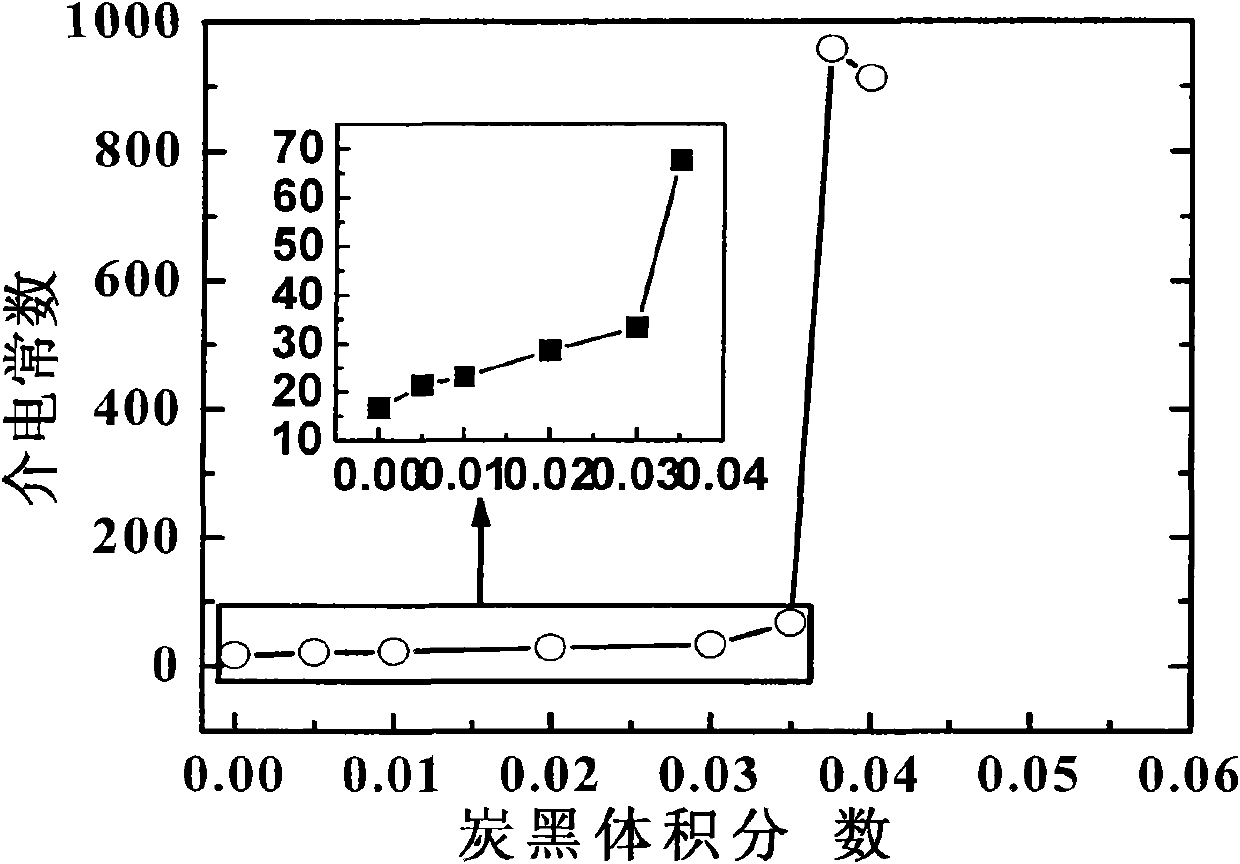

[0036] From attached image 3 It can be seen that the percolation threshold of the three-phase composite composed of carbon black, barium titanate and silicone rubber occurs when the volume fraction of carbon black is 3.5%. When the volume content of carbon black is 3.5%, the three-phase composite has a high dielectric constant ( image 3 Known), low dielectric loss ( Figure 5 6 in) and higher elasticity ( Figure 7 3 in it can be known).

[0037] Table 1

[0038]

[0039] Description: Each composite contains 40vol% BaTiO 3 , with a mass of 13.054g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com