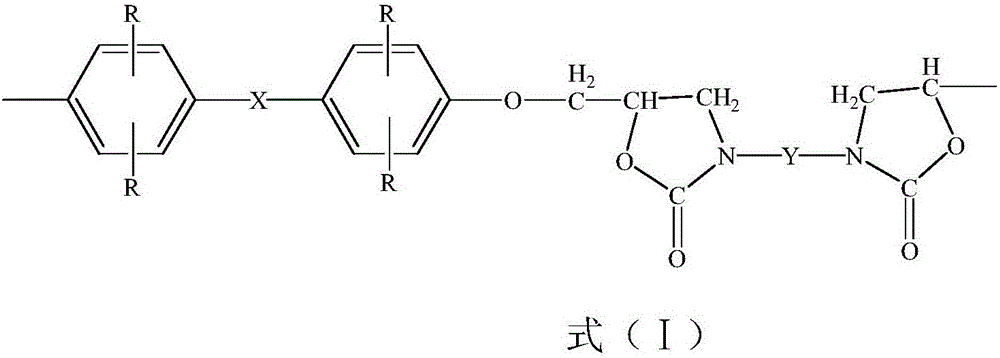

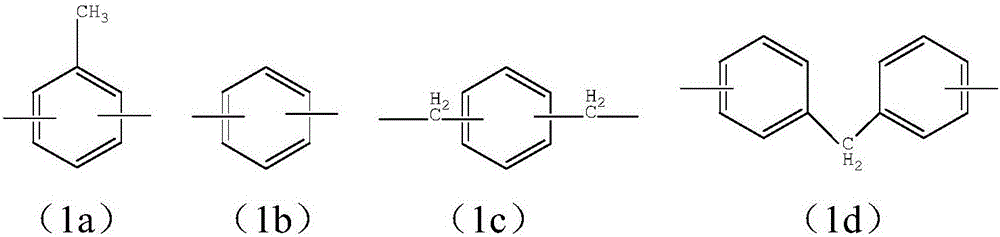

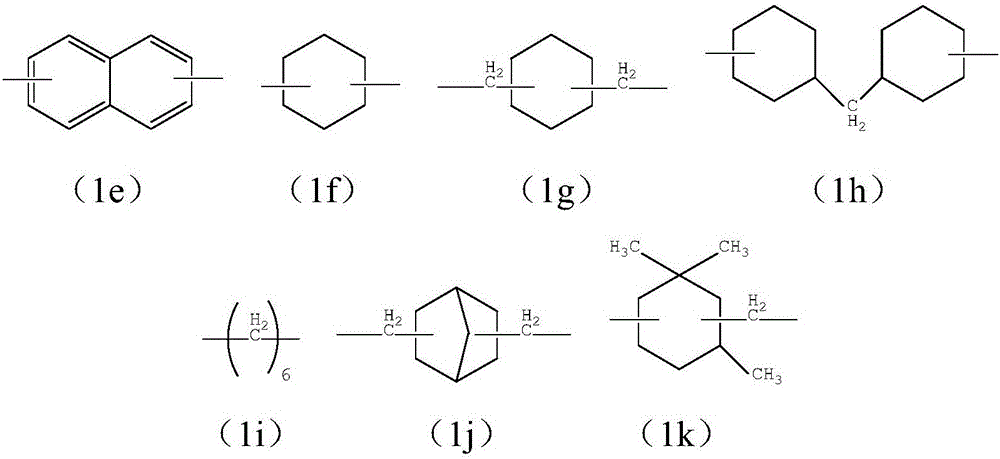

Halogen-free thermosetting resin composition, prepreg comprising same, laminated board and printed circuit board

A resin composition and thermosetting technology, applied in the fields of halogen-free thermosetting resin composition and prepreg containing it, laminates and printed circuit boards, can solve the problems of general dielectric constant and dielectric loss of resin composition, etc., Achieve the effect of increasing the glass transition temperature, reducing the probability of moisture absorption and explosion, and reducing the value of dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to facilitate understanding of the present invention, the present invention enumerates the following examples. It should be clear to those skilled in the art that the embodiments are only for helping to understand the present invention, and should not be regarded as specific limitations on the present invention.

[0072] Test the glass transition temperature, dielectric constant, dielectric loss factor, peel strength, heat resistance, water absorption, flame retardancy and other properties of the printed circuit laminate (4 pieces of prepreg), as follows The examples are further detailed and described.

[0073] The preparation method of the copper-clad laminate adopted in the present invention is:

[0074] Mix halogen-free epoxy resin, polyphosphonate, cyanate, phosphorus-containing flame retardant, curing accelerator, and filler in a solvent in a certain proportion, control the solid content of the glue to 65%, and use 2116 glass fiber cloth Immerse the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com