Method for manufacturing high dielectric composite thin film

A composite film and flat film technology, applied in the field of electronic functional materials, can solve the problems of low dielectric constant and limited application, and achieve the effect of high dielectric constant value, low raw material cost, and high dielectric performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

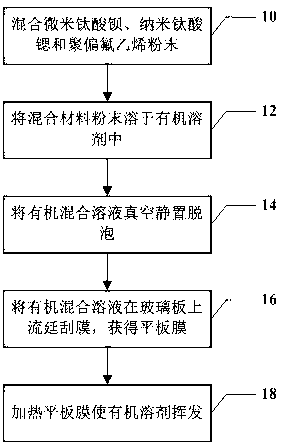

[0057] (1) Weigh 2 g of micro-barium titanate and 0.5 g of nano-strontium titanate, and mix them by ball milling for 2 hours to obtain nano-mixed powder A1;

[0058] (2) Weigh 2.5g of polyvinylidene fluoride powder, and ball mill and mix with the above-mentioned 2.5g of nano-mixed powder A1 for 2 hours to obtain mixed material powder B1;

[0059] (3) Add the mixed material powder B1 into 15ml of N,N-dimethylformamide (DMF), and stir thoroughly under ultrasonic for 3 hours until the polyvinylidene fluoride powder is completely dissolved to obtain a viscous organic mixed solution C1;

[0060] (4) Put the organic mixed solution C1 at room temperature for 3 hours under vacuum for degassing to obtain a bubble-free mixed solution D1;

[0061] (5) Cast and scrape the bubble-free mixed solution D1 on a glass plate to make a flat film E1 with a thickness of about 150 μm;

[0062] (6) Remove the solvent from the flat film E1 at 60°C for 8 hours in a vacuum, and after the film falls off...

example 2

[0065] (1) Weigh 2 g of micro-barium titanate and 0.5 g of nano-strontium titanate, and mix them by ball milling for 2 hours to obtain nano-mixed powder A2;

[0066] (2) Weigh 12.5g of polyvinylidene fluoride powder, and ball mill and mix with the above-mentioned 2.5g of nano-mixed powder A2 for 3 hours to obtain mixed material powder B2;

[0067] (3) Add the mixed material powder B2 to 75ml of N,N-dimethylformamide (DMF), and stir thoroughly under ultrasonic for 4 hours until the polyvinylidene fluoride powder is completely dissolved, and a viscous organic mixed solution C2 is obtained;

[0068] (4) Put the organic mixed solution C2 at room temperature in vacuum for 5 hours for degassing to obtain a bubble-free mixed solution D2;

[0069] (5) Cast and scratch the bubble-free mixed solution D2 on a glass plate to make a flat film E2 with a thickness of about 150 μm;

[0070] (6) Remove the solvent from the flat film E2 at 60°C for 8 hours in a vacuum. After the film falls off...

example 3

[0073] (1) Weigh 5 g of micro-barium titanate and 0.5 g of nano-strontium titanate, and mix them by ball milling for 2 hours to obtain nano-mixed powder A3;

[0074] (2) Weigh 5.5g of polyvinylidene fluoride powder, and ball mill and mix with the above-mentioned 5.5g of nano-mixed powder A3 for 4 hours to obtain mixed material powder B3;

[0075] (3) Add the mixed material powder B3 into 33ml of N,N-dimethylformamide (DMF), and stir thoroughly under ultrasonic for 3 hours until the polyvinylidene fluoride powder is completely dissolved, and a viscous organic mixed solution C3 is obtained;

[0076] (4) Put the organic mixed solution C3 at room temperature for 3 hours in vacuum to defoam, and obtain the mixed solution D,3 without bubbles;

[0077] (5) Cast and scrape the bubble-free mixed solution D3 on a glass plate to make a flat film E3 with a thickness of about 150 μm;

[0078] (6) Remove the solvent from the flat film E3 in vacuum at 60°C for 24 hours. After the film falls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com