A low-temperature sinterable high dielectric constant zinc-niobium-titanium microwave dielectric ceramic and its preparation method

A technology of microwave dielectric ceramics and high dielectric constant, applied in the direction of ceramics, inorganic insulators, etc., can solve the problems of high energy consumption, high production cost, expensive raw materials, etc., and achieve the effect of reducing production cost and being easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

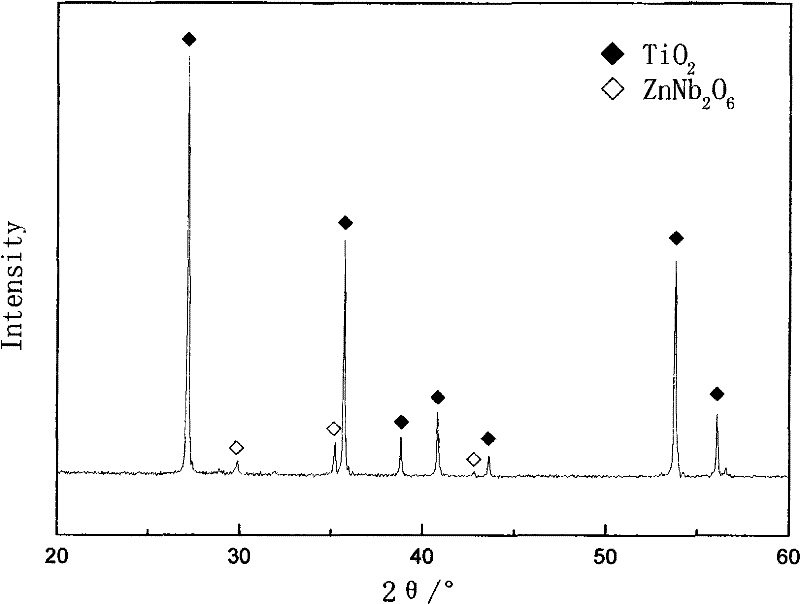

Embodiment 1

[0026] In this example, nano-TiO 2 and analytically pure ZnO, Nb 2 o 5 、 Bi 2 o 3 , V 2 o 5 and CuO, by 0.1ZnNb 2 o 6 -0.9TiO 2 +aCuO+bBi 2 o 3 +cV 2 o 5 The stoichiometric ratio ingredients, where a=5wt%, b=1wt%, c=1wt%, a, b, c are 0.1ZnNb 2 o 6 -0.9TiO 2 total weight percent.

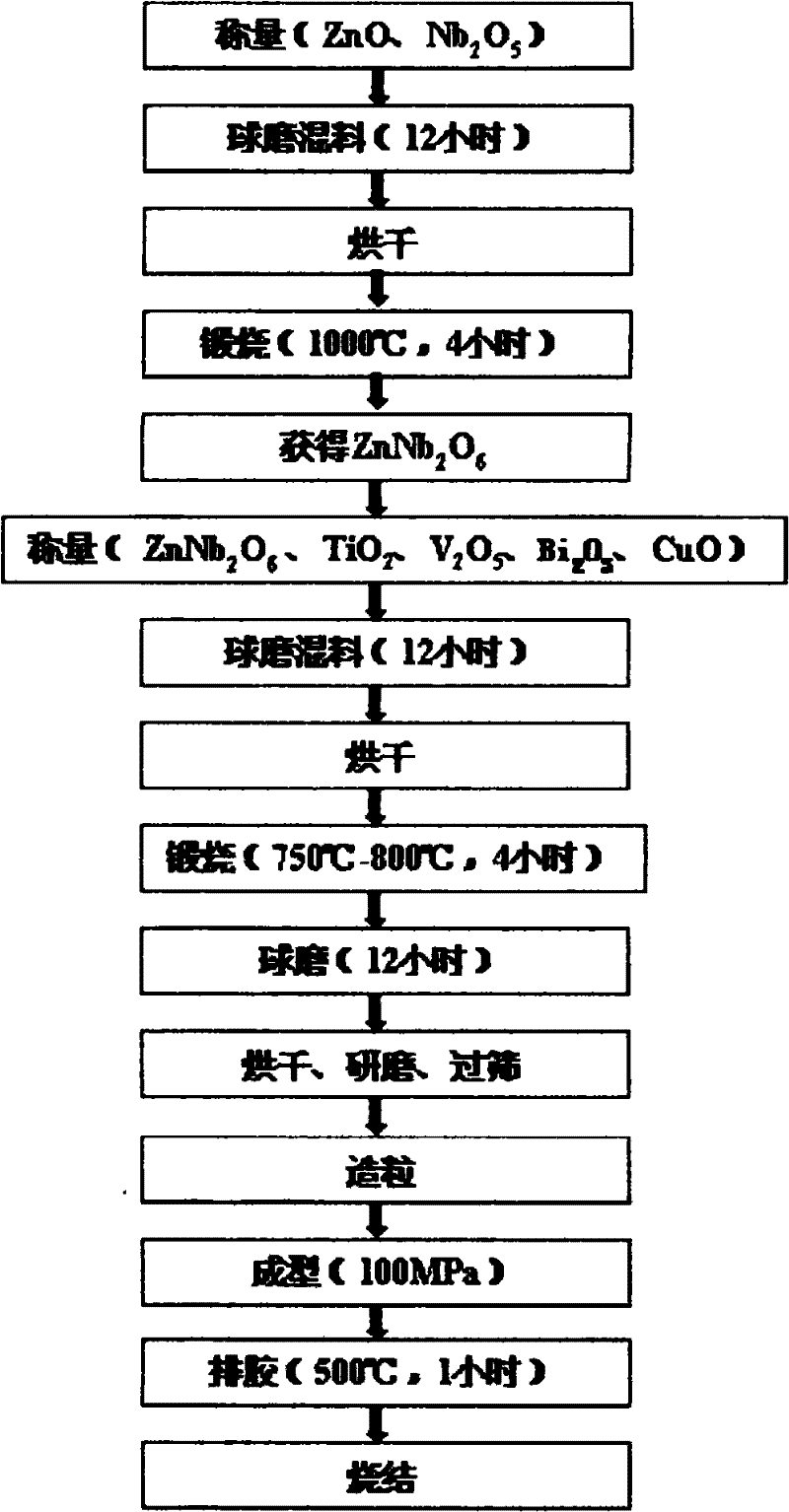

[0027] The preparation steps are:

[0028] (1) will analyze pure ZnO and Nb 2 o 5 According to the molar ratio of 1:1, mix and ball mill for 12 hours, dry it, put it into an alumina crucible, and calcinate at 1000°C for 4 hours to prepare ZnNb 2 o 6 .

[0029] (2) ZnNb 2 o 6 Add nano-TiO to the powder according to the material ratio 2 、 Bi 2 o 3 , V 2 o 5 And CuO ball milled for 12 hours and dried, the powder was put into an alumina crucible, calcined at 800°C, and the holding time was 4 hours.

[0030] (3) The calcined powder was ball-milled again for 12 hours, dried and passed through a 100-mesh sieve.

[0031] (4) The above-mentioned sieved powder was added into an aqu...

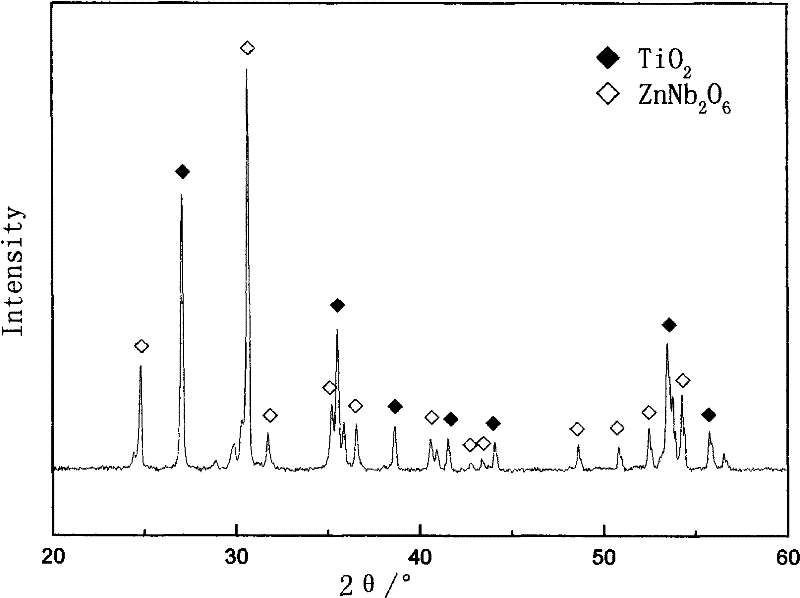

Embodiment 2

[0036] In this example, nano-TiO 2 and analytically pure ZnO, Nb 2 o 5 、 Bi 2 o 3 , V 2 o 5 and CuO, by 0.28ZnNb 2 o 6 -0.72TiO 2 +aCuO+bBi 2 o 3 +cV 2 o 5 The stoichiometric ratio ingredients, where a=5wt%, b=1wt%, c=1wt%, a, b, c are 0.28ZnNb 2 o 6 -0.72TiO 2 total weight percent.

[0037] The preparation steps are:

[0038] (1) will analyze pure ZnO and Nb 2 o 5 According to the molar ratio of 1:1, mix and ball mill for 12 hours, dry it, put it into an alumina crucible, and calcinate at 1000°C for 4 hours to prepare ZnNb 2 o 6 .

[0039] (2) ZnNb 2 o 6 Add nano-TiO to the powder according to the material ratio 2 、 Bi 2 o 3 , V 2 o 5 And CuO ball milled for 12 hours and dried, the powder was put into an alumina crucible, calcined at 750°C, and the holding time was 4 hours.

[0040] (3) The calcined powder was ball-milled again for 12 hours, dried and passed through a 100-mesh sieve.

[0041] (4) The above-mentioned sieved powder was added into an...

Embodiment 3

[0046] In this example, nano-TiO 2 and analytically pure ZnO, Nb 2 o 5 , V 2 o 5 and CuO, by 0.26ZnNb 2 o 6 -0.74TiO 2 +aCuO+cV 2 o 5 The stoichiometric ratio ingredients, where a=2.5wt%, c=1wt%, a, c account for 0.26ZnNb 2 o 6 -0.74TiO 2 total weight percent.

[0047] The preparation steps are:

[0048] (1) will analyze pure ZnO and Nb 2 o 5 According to the molar ratio of 1:1, mix and ball mill for 12 hours, dry it, put it into an alumina crucible, and calcinate at 1000°C for 4 hours to prepare ZnNb 2 o 6 .

[0049] (2) ZnNb 2 o 6 Add nano-TiO to the powder according to the material ratio 2 , V 2 o 5 And CuO ball milled for 12 hours and dried, the powder was put into an alumina crucible, calcined at 800°C, and the holding time was 4 hours.

[0050] (3) The calcined powder was ball-milled again for 12 hours, dried and passed through a 100-mesh sieve.

[0051] (4) The above-mentioned sieved powder was added into an aqueous solution of polyvinyl alcohol b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com