Ni-Zn soft magnetic ferrite material and preparation method thereof

A technology of soft ferrite and raw materials, applied in the field of Ni-Zn soft ferrite material and its preparation, can solve the problems that high-frequency, ultra-low loss Ni-Zn soft ferrite material cannot meet the demand, and achieve high saturation Effects of magnetic flux density, high resistivity, and low magnetic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

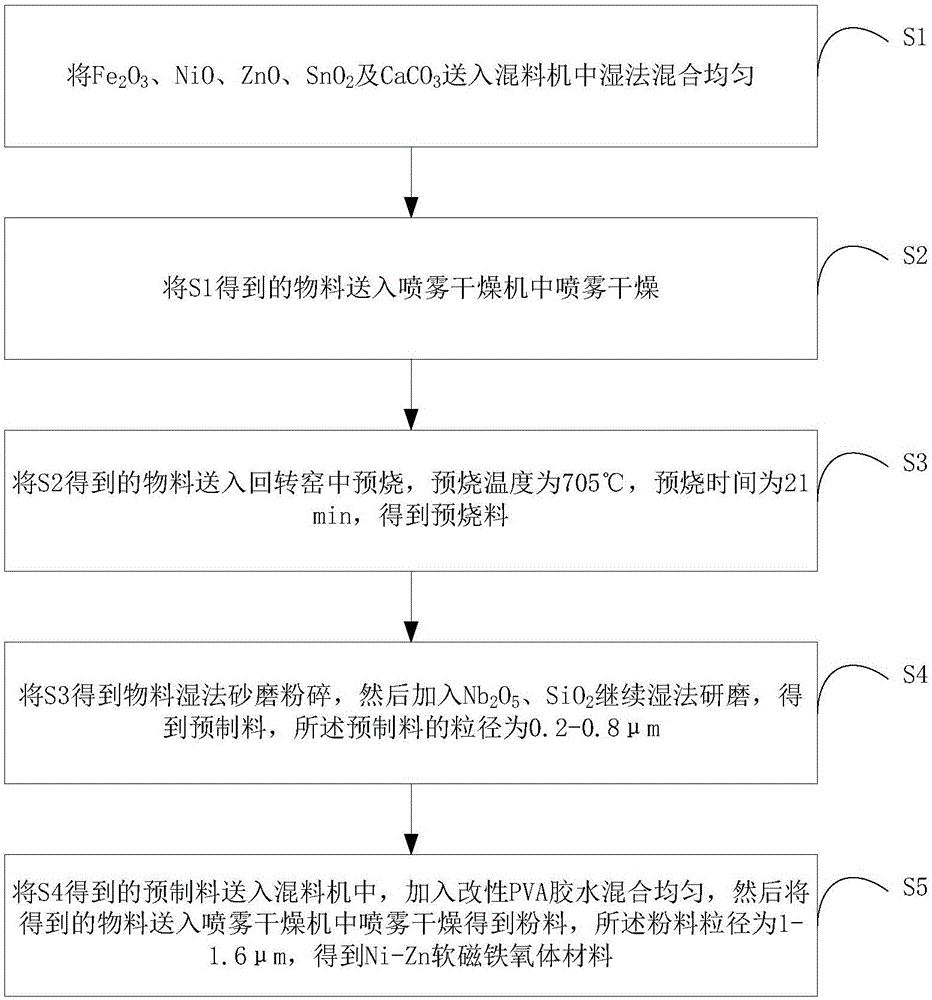

Method used

Image

Examples

Embodiment 1

[0027] A kind of Ni-Zn soft magnetic ferrite material, its raw material comprises by mole:

[0028] Fe 2 o 3 52 parts; NiO42 parts; ZnO5 parts; SnO 2 0.0001 parts; CaCO 3 0.0006 parts; Nb2O50.0001 parts; SiO20.0002 parts;

[0029] Modified PVA solution, the content of the modified PVA solution accounts for 10wt% of the total amount of raw materials.

Embodiment 2

[0031] A kind of Ni-Zn soft magnetic ferrite material, its raw material comprises by mole:

[0032] Fe 2 o 3 55 parts; NiO39 parts; ZnO8 parts; SnO 2 0.0006 parts; CaCO 3 0.0001 copies; Nb 2 o 5 0.0002 parts; SiO 2 0.0001 copies;

[0033] Modified PVA solution, the content of the modified PVA solution accounts for 5wt% of the total amount of raw materials.

Embodiment 3

[0035] A kind of Ni-Zn soft magnetic ferrite material, its raw material comprises by mole:

[0036] Fe 2 o 3 53 parts; NiO40 parts; ZnO5.2 parts; SnO 2 0.00012 parts; CaCO 3 0.00013 copies; Nb 2 o 5 0.00012 parts; SiO 2 0.00012 copies;

[0037] Modified PVA solution, the content of the modified PVA solution accounts for 6wt% of the total amount of raw materials.

[0038] The raw material of described modified PVA solution comprises by weight: 21 parts of PVA, 43 parts of water, 1.2 parts of modifier neopentyl glycol, 1.1 parts of modifier methylpropanediol, 1.2 parts of preservative salicylic acid, 0.6 parts Emulsifier, 2.1 parts of polycarbosilane, 2.5 parts of triethanolamine, 1.2 parts of glycerol.

[0039] During the preparation of the modified PVA solution, mix PVA, water, triethanolamine and glycerin evenly, heat up from room temperature to 62°C and continue to stir for 32min, then cool down to 46°C, add neopentyl glycol, methyl propylene glycol, Emulsifier, pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com