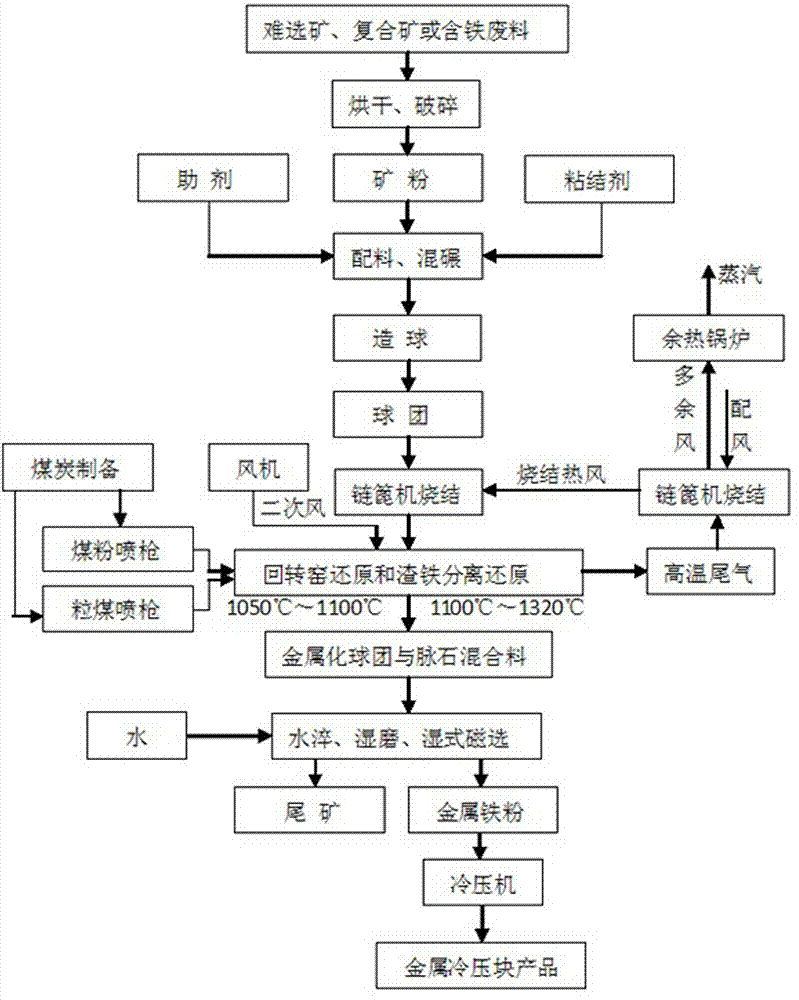

Equipment and method for carrying out slag-iron separation and iron reduction on refractory ore, complex ore and chemical industry ferruginous waste

A technology of compound ore and refractory ore, which is applied in the field of metallurgy, can solve the problems of long reduction time, low product quality, waste of resources, etc., and achieve the effect of uniform reduction atmosphere and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

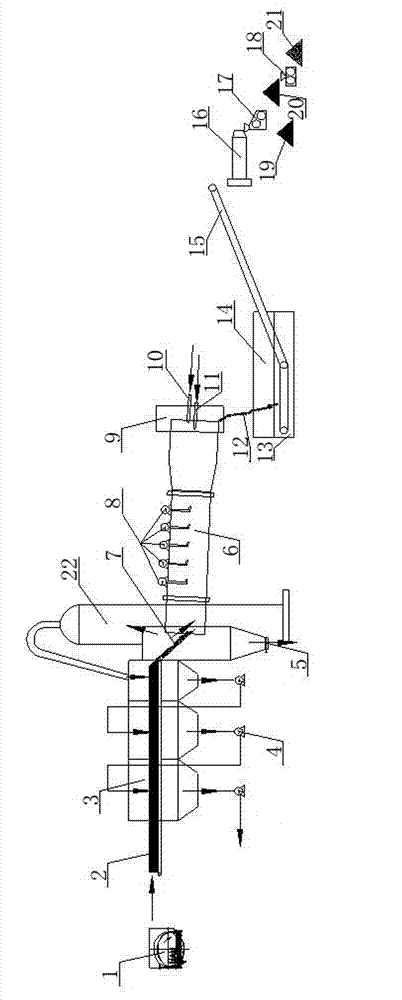

Method used

Image

Examples

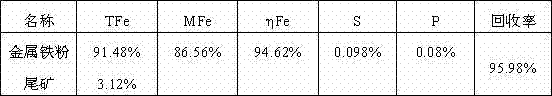

Embodiment 1

[0037] (1) Crush and grind Inner Mongolia sulfuric acid slag into a powder with -200 mesh particles accounting for more than 85% of the mass fraction. The sulfuric acid slag contains TFe: 55% to 58%, and 6.0% of the powder mass is added with calcium carbonate additives and 0.4 % binder, uniformly mixed and milled, sprayed with water to make pellets, and pellets with a diameter of 8.0-16mm were obtained, and the pellets were sent to the chain grate machine for cloth and sintering, and the reheating fan was used to supply hot air, at 1050°C Sinter for 40 minutes to make sintered pellets with a strength of 300~400N / ball. The sintered pellets enter the rotary kiln through a closed flow sieve. discharge;

[0038] (2) The sintered pellets enter the rotary kiln under airtight conditions, and the air pressure of the secondary fan on the kiln shell of the rotary kiln is controlled to be 850Pa, the air volume is 3500m3 / h, and the particle size of the granular coal spray gun at the outle...

Embodiment 2

[0044] (1) Hunan oolitic hematite is crushed and ground into a powder with -200 mesh particles accounting for more than 85% of the mass fraction. Hunan oolitic hematite contains TFe45.45%, and calcium oxide additives with a powder mass of 8.0% are added and 1.0% binder, uniformly mixed and milled, and sprayed with water to make pellets to obtain pellets with a diameter of 8.0-16mm. Sinter at 1180°C for 20 minutes to make sintered pellets with a strength of 300-400N / ball. The sintered pellets enter the rotary kiln through a closed flow sieve. Discharge from the bottom of the warehouse;

[0045] (2) The sintered pellets enter the rotary kiln under airtight conditions, and the air pressure of the secondary fan on the kiln shell of the rotary kiln is controlled to be 900Pa and the air volume is 3800m 3 / h, the granular coal spray gun at the outlet of the rotary kiln sprays reduced granular coal with a particle size of 5~25mm, the spray gun adopts the air jet conveying method to s...

Embodiment 3

[0051] (1) Crushing and grinding the Indonesian laterite nickel ore into a powder with -200 mesh particles accounting for more than 85% of the mass fraction. The Indonesian laterite nickel ore contains TFe18.58%, Ni1.8%, and calcium fluoride with a powder mass of 10.0% Auxiliary and 2.0% binder, uniformly mixed and milled, sprayed with water to make pellets to obtain pellets with a diameter of 8.0-16mm, sent the pellets to the chain grate machine for cloth and sintering, and returned to the hot air blower to supply hot air , and sintered at 1100°C for 30 minutes to make sintered pellets with a strength of 300-400N / ball. The sintered pellets enter the rotary kiln through a closed flow sieve, and the flow sieve screens out fine powder and small particles with a particle size below 5mm. The bottom of the fine powder bin is discharged;

[0052] (2) The sintered pellets enter the rotary kiln under airtight conditions, and the air pressure of the secondary fan on the kiln shell of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com