Microwave-fired muck brick and preparation method thereof

A muck brick and microwave technology, applied in the field of building materials, can solve the problems of polluting the ecological environment, waste of resources, and high energy consumption, and achieve the effects of eliminating emissions, improving production efficiency, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

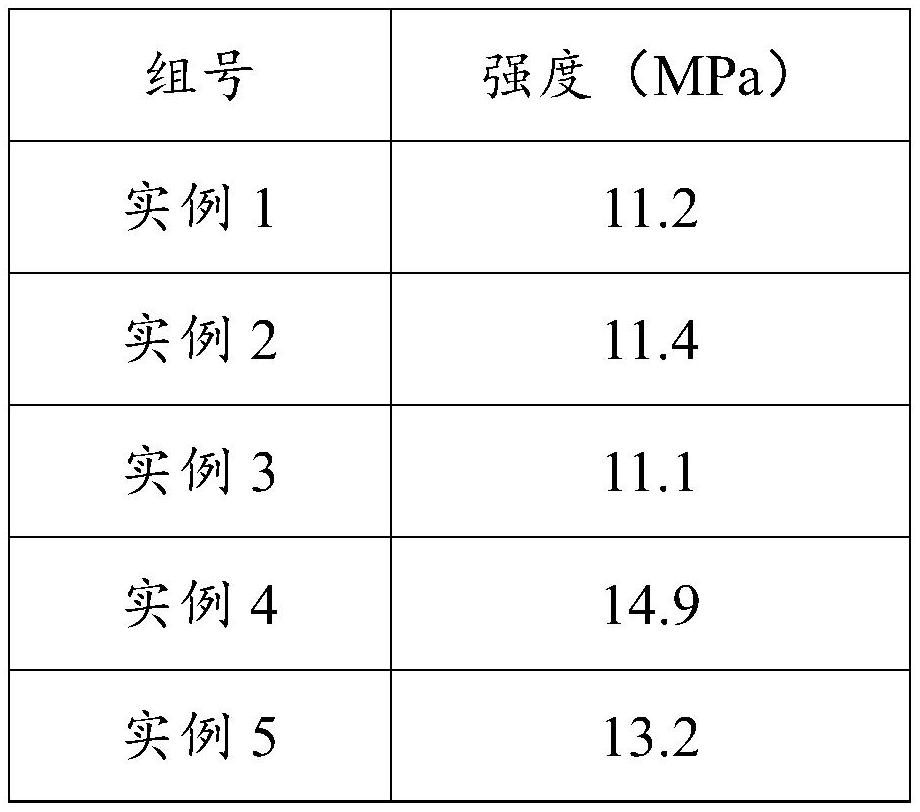

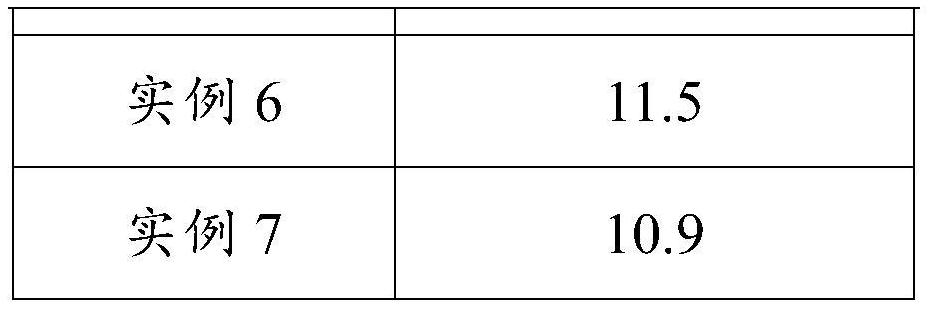

Examples

preparation example Construction

[0032] In yet another embodiment of the present invention, a method for preparing microwave-fired muck bricks is provided, which includes the following steps: stirring water and cementitious materials evenly to obtain a mixture; wherein the cementitious materials are dregs and ferroferric oxide A mixture of powders; aging the mixture and pressing the aged mixture into adobe; microwave drying the adobe to obtain a dry adobe; roasting the dried adobe in a microwave and then cooling to obtain a microwave-fired slag brick.

[0033] Concretely, the specific method of mixing the water and the cementitious material evenly to obtain the mixture is as follows: firstly weigh the slag and ferric oxide powder in proportion and stir evenly to obtain the cementitious material, preferably, the cementitious material is calculated by mass percentage Including: 80% to 95% of slag and 5% to 20% of ferric oxide powder.

[0034] A certain proportion of water is added to the gelling material and st...

example 1

[0043] Step 1: Scale the slag and ferric oxide powder and mix together initially to obtain a cementitious material. Wherein, by mass percentage, it includes: 90% of slag and 10% of ferric oxide powder. Add a certain proportion of water into the gelling material and stir evenly to obtain a mixture, wherein the mass ratio of water to the gelling material is 1:2.

[0044] Step 2: Aging the mixture for 7 days, and then pressing the aged mixture into adobe through a 1300T press.

[0045] Step 3: Place the adobe in an industrial microwave oven, dry it under a microwave power of 800W for 17 minutes, and then cool it down to obtain a dry adobe.

[0046] Step 4: Place the dry brick in an industrial microwave oven, first bake it at a microwave power of 1800-2000W for 15-17 minutes, then continue to bake it at a microwave power of 2800-3000W for 20-22 minutes, and then cool it down.

example 2

[0048] Step 1: Scale the slag and ferric oxide powder and mix together initially to obtain a cementitious material. Among them, by mass percentage, it includes: 85% of slag and 15% of ferric oxide powder. Add a certain proportion of water into the gelling material and stir evenly to obtain a mixture, wherein the mass ratio of water to the gelling material is 1:2.

[0049] Step 2: Aging the mixture for 10 days, and then pressing the aged mixture into adobe through a 1300T press.

[0050] Step 3: Place the adobe in an industrial microwave oven, dry it under a microwave power of 900W for 16 minutes, and then cool it down to obtain a dry adobe.

[0051] Step 4: Place the dried brick in an industrial microwave oven, first bake it at a microwave power of 1900W for 16 minutes and then cool it, then bake it at a microwave power of 2900W for 21 minutes and then cool it to obtain a microwave fired slag brick.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com