Method for preparing low-temperature cofired dielectric ceramic and material and sintering aid of low-temperature cofired dielectric ceramic

A dielectric ceramic and low-temperature co-firing technology, which is applied in the field of dielectric ceramic materials, can solve problems such as high requirements for production equipment and process control, good low-temperature sintered ceramic dielectric materials, and degradation of electrical properties of sintering aid materials, so as to promote crystal grains. Refinement, reduce dielectric loss value, improve insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

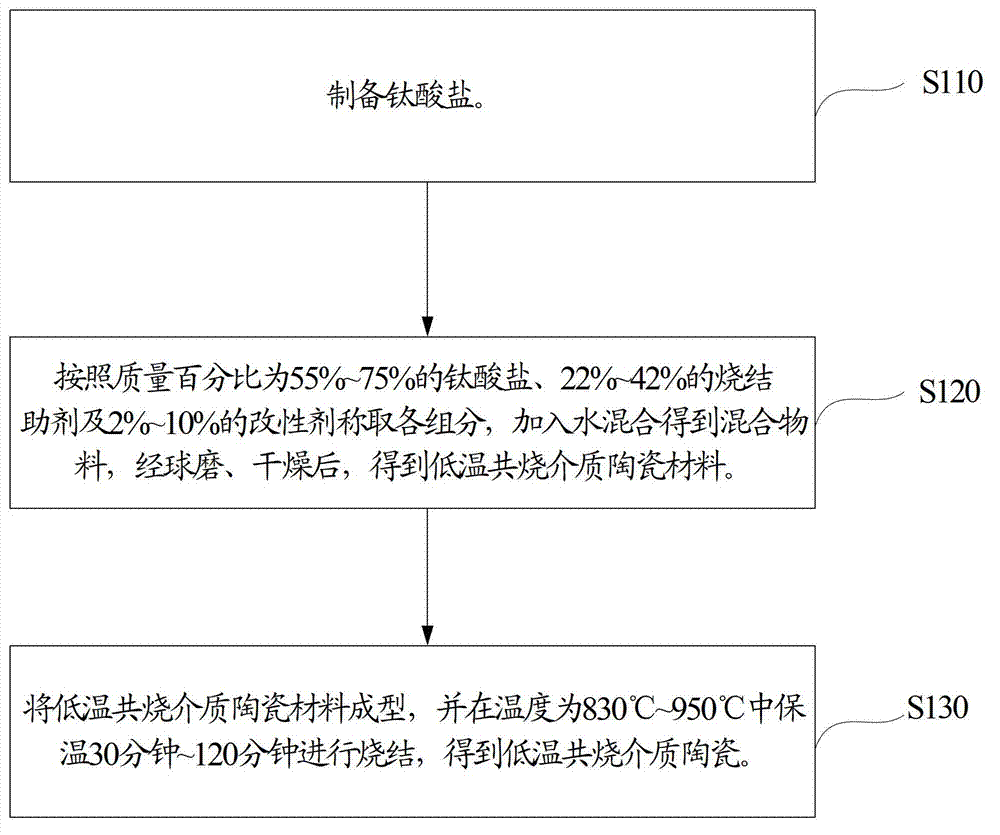

[0029] Such as figure 1 Shown, the preparation method of the low-temperature co-fired dielectric ceramic of one embodiment, comprises the following steps:

[0030] Step S110: Prepare titanate. According to mass percentage, titanate includes 72%~90% Zn 1-x Mg x TiO 3 and 10%~28% Ba 2 Ti 9 o 11 , where 0.03≤X≤0.3.

[0031] Among them, the method for preparing titanate is solid phase synthesis. And the preparation of titanate comprises the following steps:

[0032] Submicron zinc oxide (ZnO), magnesium oxide (MgO), barium carbonate (BaCO 3 ) and titanium dioxide (TiO 2 ) as raw material, according to Zn in titanate 1-x Mg x TiO 3 and Ba 2 Ti 9 o 11 The mass percentages are respectively 72%~90% and 10%~28% for batching; then, mix according to the mass ratio of the total mass of raw materials and deionized water as 1:1.6~1.8, after mixing by ball milling, at a temperature of Calcining at 900°C to 1050°C for 1 hour to 4 hours to obtain titanate.

[0033] Step S120:...

Embodiment 1

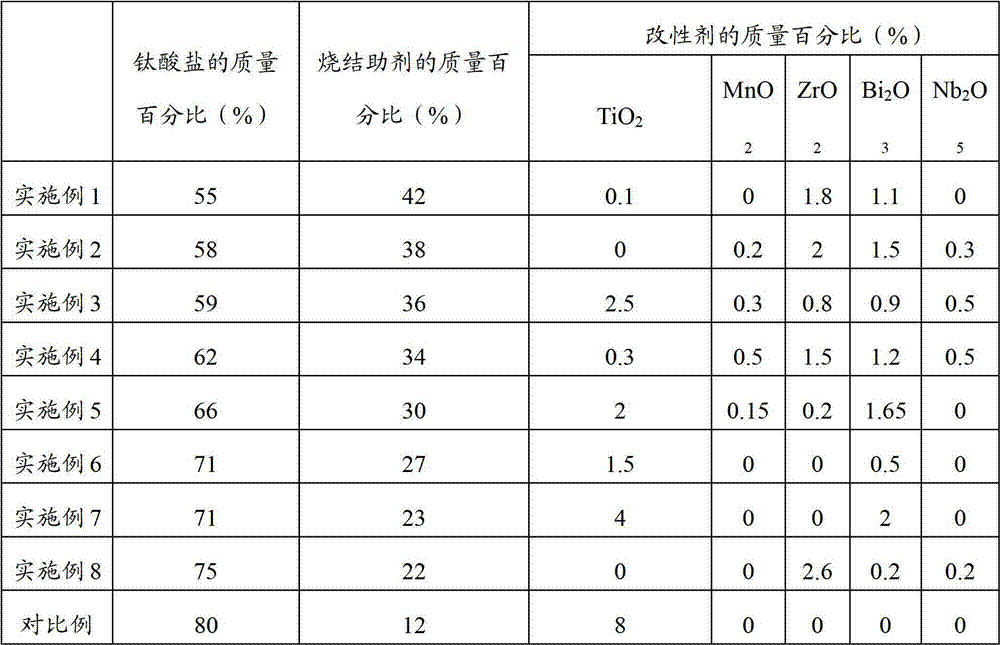

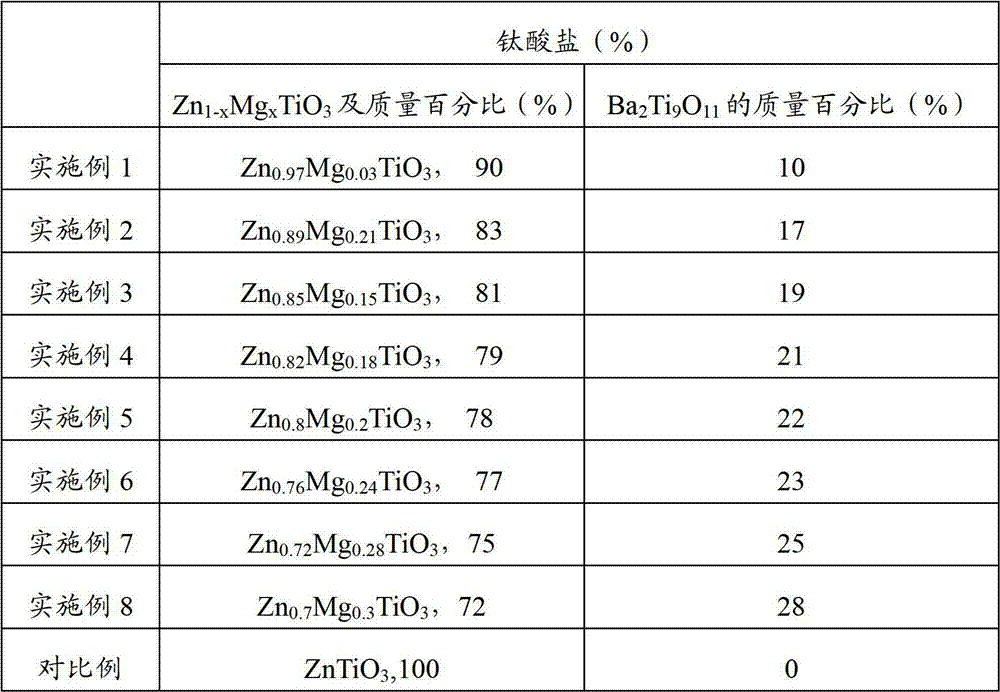

[0045] The composition of the low temperature co-fired dielectric ceramic material in this embodiment is shown in Table 1, Table 2 and Table 3.

[0046] The preparation of low temperature co-fired dielectric ceramics in this embodiment is as follows:

[0047] (1) Preparation of titanate: submicron zinc oxide (ZnO), magnesium oxide (MgO), barium carbonate (BaCO 3 ) and titanium dioxide (TiO 2 ) as raw material, according to Zn in titanate 0.97 Mg 0.03 TiO 3 and Ba 2 Ti 9 o 11 Then, according to the mass ratio of the total mass of the raw materials and deionized water is 1:1.6, mixed by ball milling, dried, and calcined at a temperature of 1050 ° C for 4 hours to obtain titanate.

[0048] (2) Preparation of sintering aid: aluminum chloride (AlCl 3 ), cobalt chloride (CoCl 2 ), lanthanum chloride (LaCl 3 ), neodymium chloride (NdCl 3 ) raw materials, each raw material is formulated into an aqueous solution respectively, and mixed according to the mass percentage of eac...

Embodiment 2

[0053] The composition of the low temperature co-fired dielectric ceramic material in this embodiment is shown in Table 1, Table 2 and Table 3.

[0054] The preparation of low temperature co-fired dielectric ceramics in this embodiment is as follows:

[0055] (1) Preparation of titanate: submicron zinc oxide (ZnO), magnesium oxide (MgO), barium carbonate (BaCO 3 ) and titanium dioxide (TiO 2 ) as raw material, according to Zn in titanate 0.89 Mg 0.21 TiO 3 and Ba 2 Ti 9 o 11 Then, according to the mass ratio of the total mass of raw materials and deionized water of 1:1.8, mix them by ball milling, dry them, and calcinate them at a temperature of 900°C for 4 hours to obtain titanates.

[0056] (2) Preparation of sintering aid: aluminum chloride (AlCl 3 ), copper chloride (CuCl 2 ), lanthanum chloride (LaCl 3 ), dysprosium chloride (DyCl 3 ) as raw materials, each raw material is prepared into an aqueous solution respectively, and mixed according to the mass percentag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com