Terahertz waveband medium material, preparation method and method of preparing dielectric medium therefrom

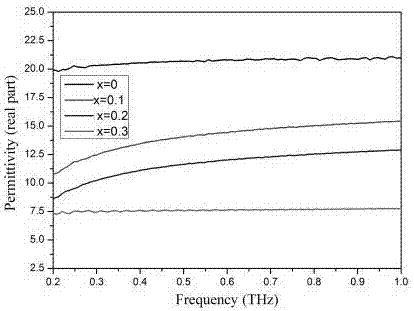

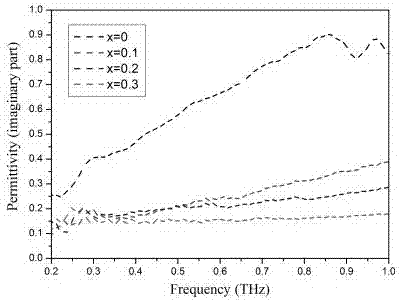

A dielectric material and terahertz technology, applied in the field of communication, can solve the problems of high sintering temperature and high dielectric loss, and achieve the effect of low sintering temperature, low dielectric loss and moderate dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

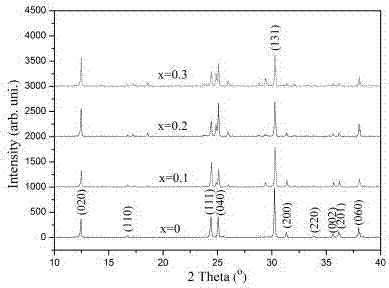

[0031]Example 1. A terahertz band dielectric material, the stoichiometric formula of the dielectric material is [(Mg 1- x Al 2 / 3x ) 1 / 3 Nb 2 / 3 ]O 2 + ywt% ABSMV; where 0≤x≤0.3, y=1 or 2.

[0032] The aforementioned terahertz band dielectric material is prepared according to the following steps:

[0033] a, the raw material Al 2 o 3 , MgCO 3 and Nb 2 o 5 According to the stoichiometric general formula [(Mg 1-x Al 2 / 3x ) 1 / 3 Nb 2 / 3 ]O 2 Ingredients mixed, where 0≤ x ≤0.3, product A is obtained;

[0034] b. Mix product A, balls and water according to the volume ratio of 1:1:1, then ball mill for 3~5 hours to get product B;

[0035] c, drying the B product, and passing through a 40-80 mesh sieve (optimum 60 mesh sieve), to obtain the C product;

[0036] d. Put product C in the air at 1200±5 o C is pre-fired for 2-6 hours to obtain product D;

[0037] e. Al 2 o 3 , B 2 o 3 , SiO 2 , MgO and V 2 o 5 Mix according to the weight ratio of 2:7:8:1:2 to get...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com