Halogen-free resin composition and method for preparing copper-clad plate from the halogen-free resin composition

A technology of resin composition and copper clad laminate, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of high water absorption, large smoke generation, bad smell, etc., and achieve excellent heat resistance and moisture resistance, low dielectric loss, and the effect of improving the electrical properties of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

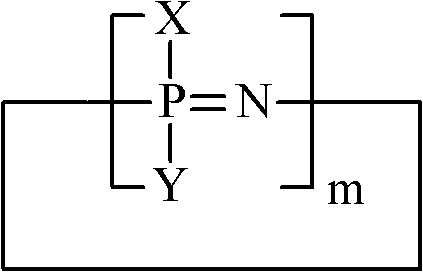

Method used

Image

Examples

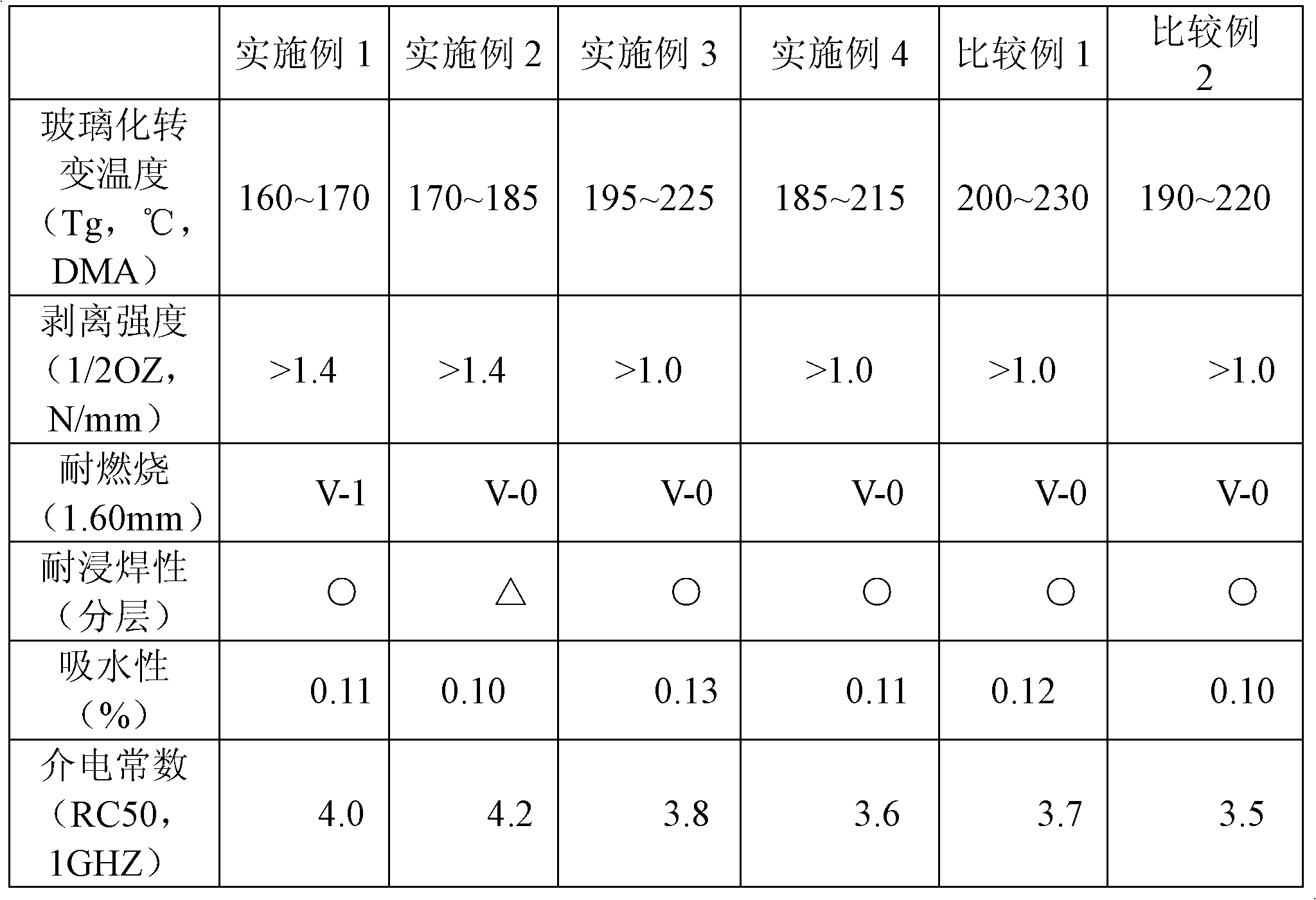

Embodiment 1

[0048] Add solvent, hexachlorocyclotriphosphazene, allylphenol (with ortho-allylphenol as the main component), and acid-binding agent into the reaction device, stir, pass in nitrogen protection, heat to 50-120°C, and then Add a catalyst into the reaction device, react for 5-16 hours, cool to room temperature, filter with suction, carry out pressure distillation on the filtrate, evaporate the solvent, and obtain a brown powder or viscous product. After taking 30g of the above product and dissolving it in an organic solvent, add 50g of DCPD epoxy resin (the selected DCPD epoxy resin is HP-7200H (DIC), equivalent 275-280), 20g of DCPD phenolic resin (the selected DCPD phenolic resin is Nihon Petro -chemical DPP-600M), appropriate amount of imidazole and 2,5-bis(2-ethylhexanoyl peroxy), stir and mix evenly to obtain glue. Select 300×300cm E-glass fiber cloth with smooth and flat surface, evenly coat the above glue, and bake in an oven at 155°C for 7 minutes to make a prepreg. Sta...

Embodiment 2

[0050] Add solvent, hexachlorocyclotriphosphazene, allylphenol (with ortho-allylphenol as the main component), and acid-binding agent into the reaction device, stir, pass in nitrogen protection, heat to 50-120°C, and then Add a catalyst into the reaction device, react for 5-16 hours, cool to room temperature, filter with suction, carry out pressure distillation on the filtrate, evaporate the solvent, and obtain a brown powder or viscous product. After taking 30g of the above product and dissolving it in an organic solvent, add 40g of DCPD benzoxazine (the selected DCPD benzoxazine is MT36000 (Huntsman)), 20g of DCPD epoxy resin (the selected DCPD epoxy resin is HP-7200H (DIC ), equivalent weight 275-280), styrene / maleic anhydride 10g (selected anhydride is EF-30, Sartomer), appropriate amount of imidazole and 2,5-bis(2-ethylhexanoyl peroxy), stirring Mix evenly to obtain glue. Select 300×300cm E-glass fiber cloth with smooth and flat surface, evenly coat the above glue, and b...

Embodiment 3

[0052] Add solvent, hexachlorocyclotriphosphazene, allylphenol (with ortho-allylphenol as the main component), and acid-binding agent into the reaction device, stir, pass in nitrogen protection, heat to 50-120°C, and then Add a catalyst into the reaction device, react for 5-16 hours, cool to room temperature, filter with suction, carry out pressure distillation on the filtrate, evaporate the solvent, and obtain a brown powder or viscous product. After dissolving 30g of the above product in an organic solvent, add 30g of DCPD cyanate (the selected DCPD cyanate is LONZA-Primaset BADCy), 20g of 4,4'-diphenylmethane bismaleimide, DCPD epoxy resin 20g (the selected DCPD epoxy resin is HP-7200H (DIC), equivalent weight 275-280), an appropriate amount of aluminum acetylacetonate, stirred and mixed evenly to obtain glue. Select 300×300cm E-glass fiber cloth with smooth and flat surface, evenly coat the above glue, and bake in an oven at 155°C for 7 minutes to make a prepreg. Stack fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com