A kind of halogen-free thermosetting resin composition, prepreg, laminate and printed circuit board using it

A resin composition, thermosetting technology, applied in the fields of laminates and printed circuit boards, halogen-free thermosetting resin compositions, and prepregs, which can solve the problems of peel strength, interlayer adhesion, low flexural strength, dielectric Poor performance, poor dielectric properties of cured products, etc., to achieve the effects of good processability, enhanced high heat resistance, and excellent flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0084] Synthesis of DOPO-MAH Containing Phosphoric Anhydride

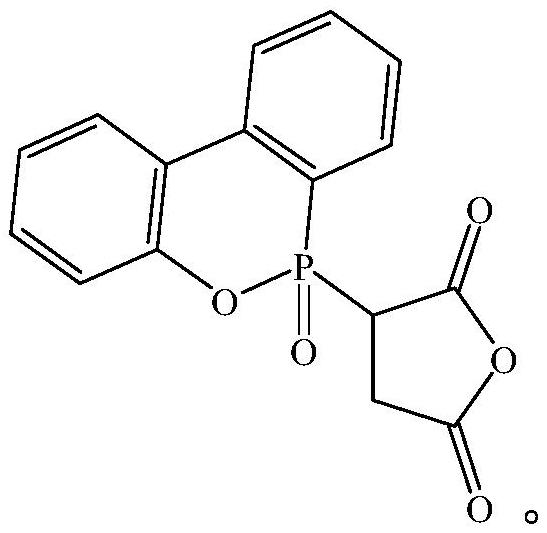

[0085] 49g of maleic anhydride and 108g of DOPO were stirred in a four-necked flask equipped with a stirrer and a thermometer, while nitrogen was introduced, and then the temperature was raised to 125°C, and the reaction was carried out at this temperature for 3h to obtain a product, numbered as DOPO-MAH. Its structure is:

[0086]

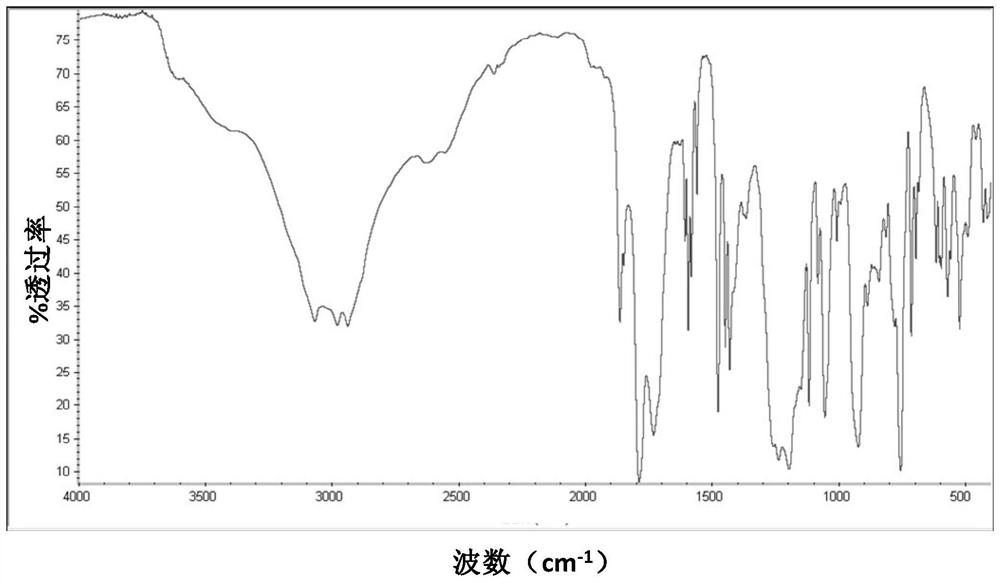

[0087] Characterized by infrared spectrometer Nicolet TR-460, such as figure 1 As shown in the infrared spectrum of DOPO-MAH, it can be seen that the P-H in the DOPO structure is at 2361 cm -1 , 2342cm -1 The characteristic absorption disappears, indicating that it has completely reacted; 1865cm -1 And 1787cm -1 In order to absorb the characteristics of the five-membered cyclic acid anhydride, it is explained that the newly generated structure contains the structure of the five-membered acid anhydride, and the phosphoric acid anhydride containing the above structure is synthesiz...

Embodiment 1-9

[0089] As shown in Table 1 and Table 2 (the amount of components is in parts by weight), the phosphoric anhydride, halogen-free epoxy resin, curing accelerator, halogen-free flame retardant and filler are mixed in a solvent in a certain proportion, and the control The solid content of the glue is 65%. The above glue is impregnated with 2116 glass fiber cloth to control the appropriate thickness, and then baked in an oven at 115 to 175 ° C for 2 to 15 minutes to make prepregs, and then several sheets of prepregs are stacked. Together, stack 18μRTF copper foil on both sides, the curing temperature is 170 ~ 250 ℃, and the curing pressure is 25 ~ 60kg / cm 2 , and the curing time is 60 to 300min to make a copper clad laminate. The composition of the resin composition and the performance test standard of the copper clad laminate are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com