An Electric Field-Induced Method for Ordered Domain Structures in Complex Perovskites

An electric field-induced, composite perovskite technology, applied in the direction of material selection, can solve the problems of deteriorating Q value, high annealing temperature, long annealing time, etc., and achieve lower dielectric loss value, lower annealing temperature, and shorten annealing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1. A method for inducing an ordered domain structure in a complex perovskite by an electric field, characterized in that: the steps are as follows:

[0026] a. Prepare composite perovskite ceramics according to conventional techniques;

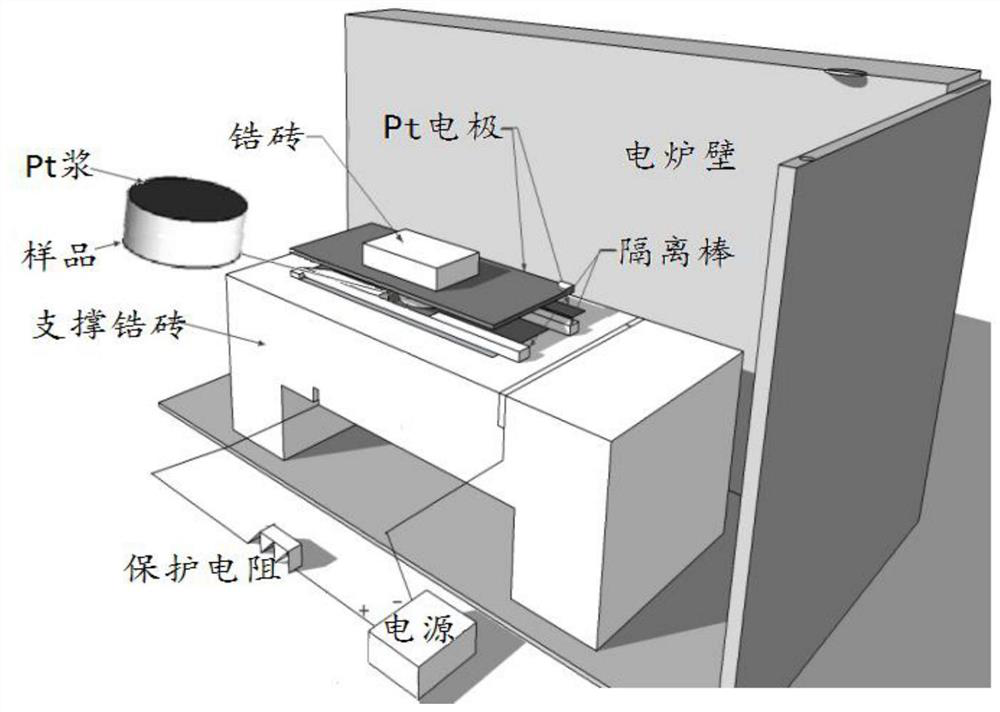

[0027] b. the composite perovskite ceramics prepared in step a is annealed, specifically as follows: see figure 1 , apply Pt slurry on both sides of the composite perovskite ceramics, and put Pt wire electrodes on both sides of the composite perovskite ceramics and press them with zirconium bricks. After supporting the above composite perovskite ceramics with zirconium bricks, put the Pt wire The electrodes are drawn out of the electric furnace, connected to the positive and negative poles of the AC power supply, and then an alternating electric field (about 700V) is applied through the AC power supply. Example) The composite perovskite ceramics were annealed for 100-180min at high temperature (120min is the optimum, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com