A micromechanical resonator, its preparation and frequency fine-tuning correction method

A technology of micro-mechanics and resonators, applied in impedance networks, electrical components, etc., can solve problems such as limitations and deterioration of MEMS resonator performance, improve consistency, reduce device size, and reduce the complexity of design and processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] It should be noted that the diagrams provided in this embodiment are only schematically illustrating the basic ideas of the present invention, and only the components related to the present invention are shown in the drawings rather than the number, shape and size of components in accordance with actual implementation Drawing, the type, quantity and proportion of each component can be changed arbitrarily during its actual implementation, and the component layout type may also be more complicated.

[0076] The invention provides a kind of preparation method of MEMS piezoelectric resonator, comprises the following steps:

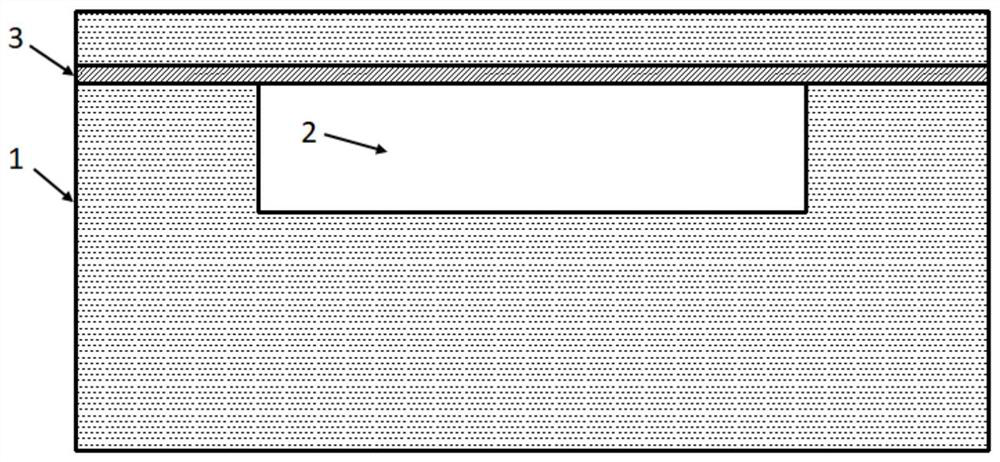

[0077] (1) if Picture 1-1 As shown, prepare a substrate silicon wafer (SOI substrate) with a concave cavity. The cavity shape can be cylinder, cuboid and irregular body (corresponding to the shape of the resonator).

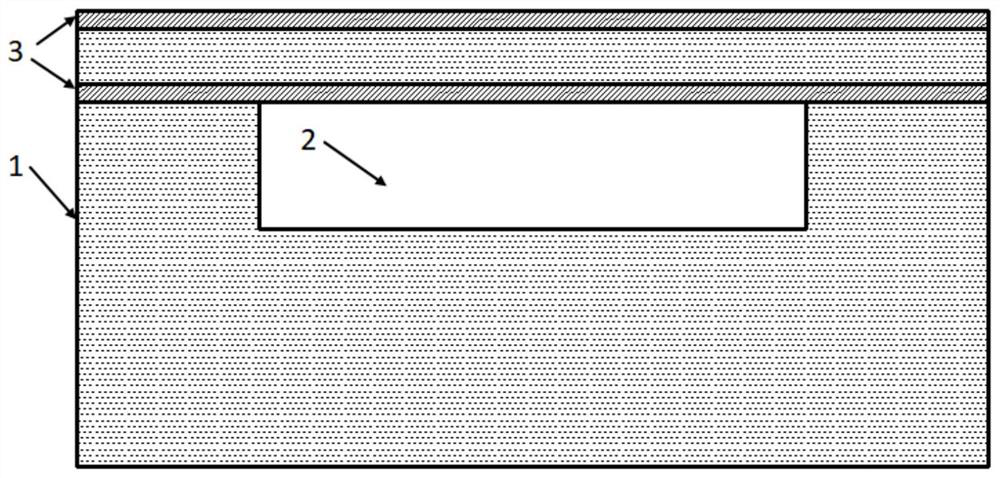

[0078] (2) if Figure 1-2 As shown, a layer of silicon oxide is prepared on the surface of SOI by thermal oxidation or chemical vapor ...

Embodiment 2

[0093] According to the structure of the resonator in Example 1, the process and structure can be changed to reduce process steps and production costs. The preparation steps are basically the same as in Example 1, the difference is:

[0094] 1. Step (3) is replaced by ion implantation or diffusion method to heavily dope the upper layer silicon of SOI, such as diagram 2-1 shown.

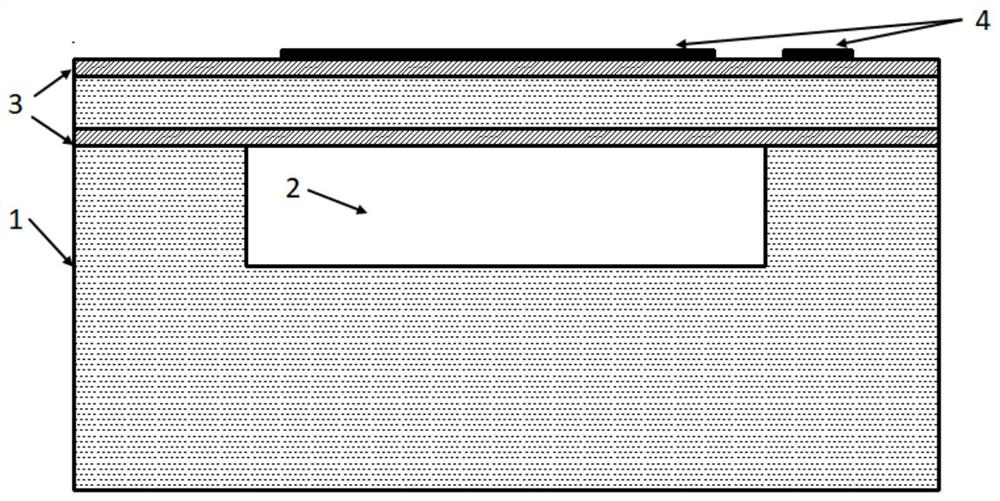

[0095] 2. Step (4) in Embodiment 1 is removed, and metal is not used as the bottom electrode, and heavily doped bottom silicon is directly used as the bottom electrode. The final structure is as Figure 2-2 shown.

Embodiment 3

[0097] Embodiment 1 only provides the method of fine-tuning to reduce the frequency of the resonator. In this embodiment, the structure of the resonant oscillator and the frequency modulation layer 9 can be changed, and the frequency can be fine-tuned by adding auxiliary frequency modulation structures at both ends of the resonant oscillator structure to realize the resonant frequency. Two-way adjustment of increase and decrease. Its preparation step flow process is basically the same as Example 1, the difference is:

[0098] 1. After completing step (6), a layer of aluminum frequency modulation layer is deposited on the upper surface of the top electrode metal layer by evaporation and sputtering, and the auxiliary frequency modulation structure area at both ends of the resonator is retained by patterned photolithography and etching. The aluminum layer is used for electrical wiring at the same time, and the positive and negative electrodes are externally connected at both ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com