Cross-coupled filter

A cross-coupling and filter technology, applied in the field of filters, can solve the problems of poor insertion loss and rejection, poor filter insertion loss, single initial direction of resonators, etc., to achieve miniaturization and improve Q value , The effect of maintaining product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

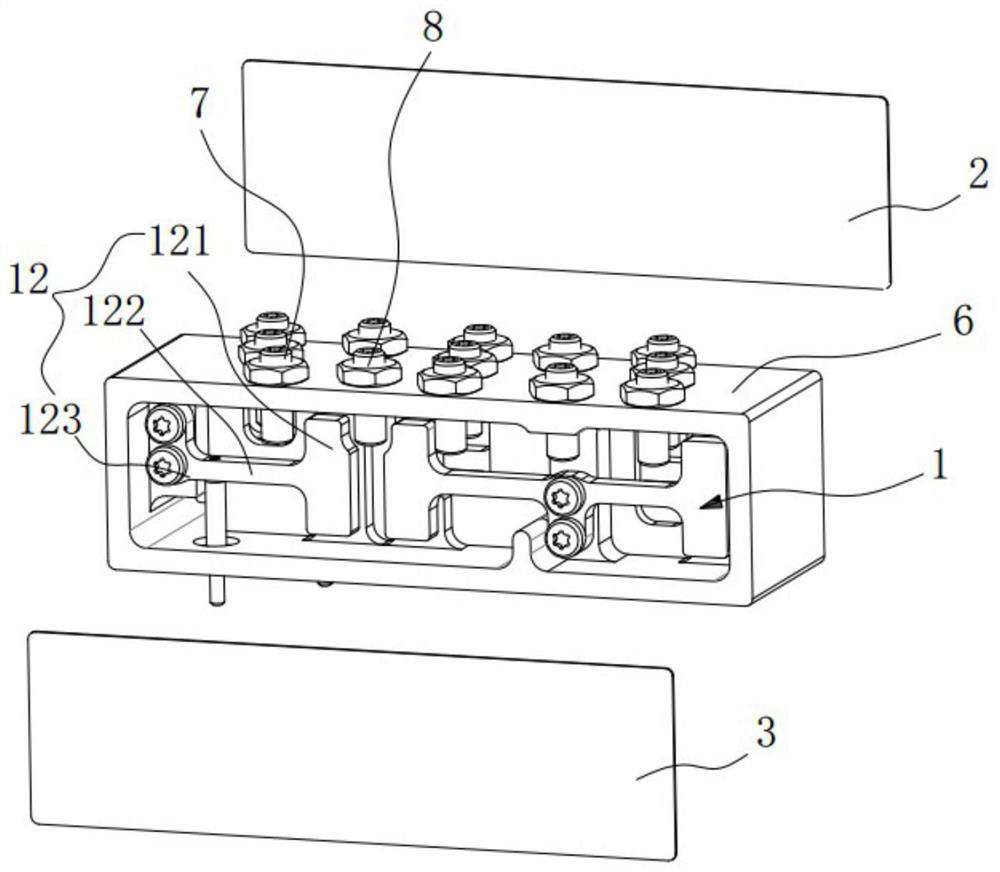

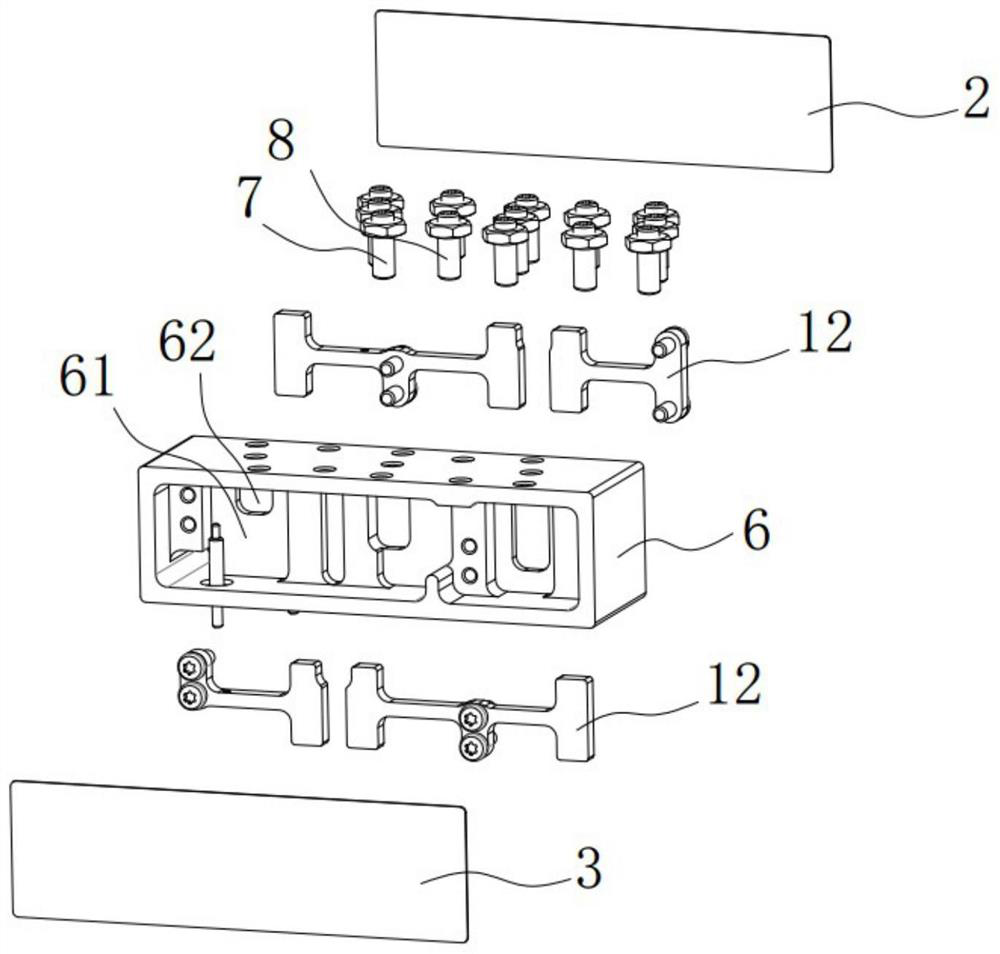

[0081] combine Figure 1 ~ Figure 3 As shown, a cross-coupled filter according to Embodiment 1 of the present invention includes a resonant structure 1, a first cover plate 2, and a second cover plate 3, wherein the first cover plate 2 and the second cover plate 3 are respectively covered on On the front and rear sides of the frame 6 , a closed filter cavity is formed in the frame, and the resonant structure 1 is separately installed in the frame 6 . Wherein, the structures of the first cover plate 2 and the second cover plate 3 can refer to the above description, and will not be repeated here. The structure of the resonant structure 1 will be described in detail below.

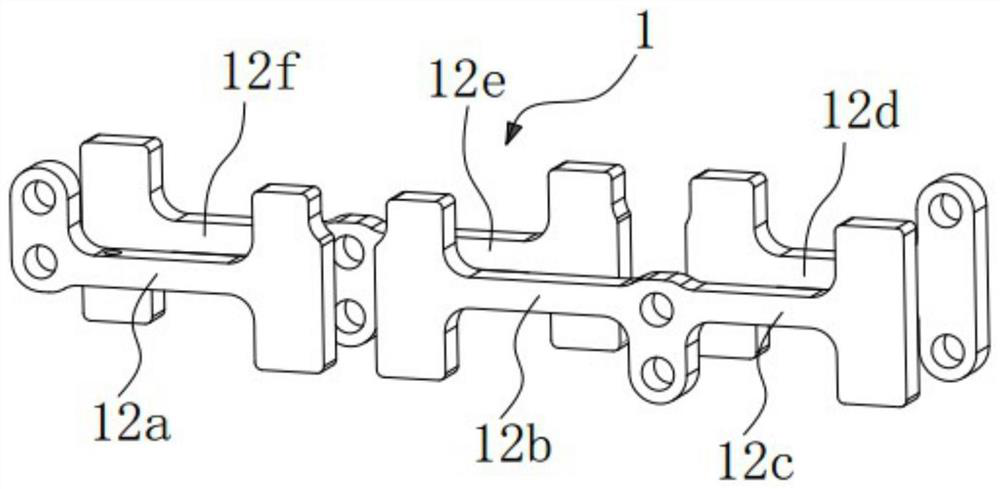

[0082] Such as image 3 As shown, the filter formed by the resonant structure 1 in Embodiment 1 of the present invention is a 6-order filter, which includes two rows of resonant units. The two rows of resonant units are not on the same plane, and are specifically arranged in layers along the front and rear ...

Embodiment 2

[0090] Such as Figure 5 As shown, a cross-coupled filter in Embodiment 2 of the present invention is an alternative implementation of Embodiment 1 above, and the filter formed by the resonant structure 1 in Embodiment 2 of the present invention is also a 6-order filter, and its It also includes two rows of resonant units, the two rows of resonant units are not on the same plane, specifically arranged in layers along the front and rear directions of the frame. Different from the first embodiment, the resonator 12a, the resonator 12b, the resonator 12f and the resonator 12e in the second embodiment constitute the minimum resonance structure A mentioned above. In this minimum resonant structure A, the resonator 12a and the resonator 12b in the same row are mainly electrically coupled, the resonator 12f and the resonator 12e in the same row are mainly magnetically coupled, and the resonator 12a and the resonator Cross-coupling occurs between 12f.

[0091] Except for the minimum...

Embodiment 3

[0094] Such as Figure 6 As shown, a cross-coupling filter according to Embodiment 3 of the present invention is also an alternative implementation manner of Embodiment 1 above. The difference from Embodiment 1 is that the two rows of resonant units in Embodiment 3 are located on the same plane, and the arrangement structure and coupling mode of the other six resonators are the same as those in Embodiment 1 above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com