Resin composition and prepreg, laminated board, printed wiring board having same

A technology of resin composition and compound, applied in the direction of printed circuit, printed circuit, printed circuit parts, etc., can solve the problem that it is difficult to choose compatible phosphorus-containing flame retardants, and achieve low dielectric loss and low dielectric Constant, the effect of dielectric constant of halogen-free flame retardant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The preparation method of the prepreg is: immersing the reinforcing material in the above-mentioned resin composition glue, then baking the impregnated reinforcing material at 50-170°C for 1-10min, and drying to obtain the present invention. prepregs.

[0089] The present invention also provides a laminate, comprising at least one prepreg mentioned above, and a metal foil formed on at least one side of the prepreg.

[0090] The laminate means that one or two of the above-mentioned prepregs are bonded together by heating and pressure to form a laminate, and then one or both sides of the laminate are bonded with metal foil by heating and pressure.

[0091] The preparation steps of the laminate are as follows: one or both sides of the above-mentioned prepregs are covered with metal foil, or at least two of the above-mentioned prepregs are stacked, and then one or both sides of the above-mentioned prepregs are covered with metal foil, and hot-pressed , to obtain a laminate...

Synthetic example 1

[0101] Synthesis Example 1: Synthesis of Phosphorous Compound (I)

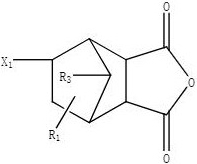

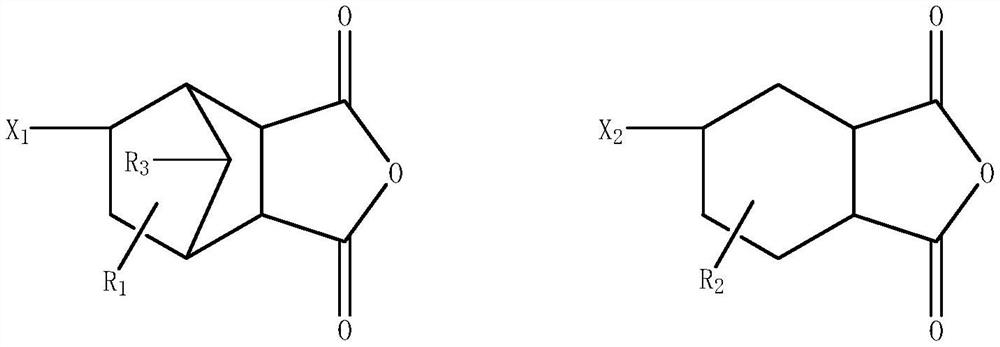

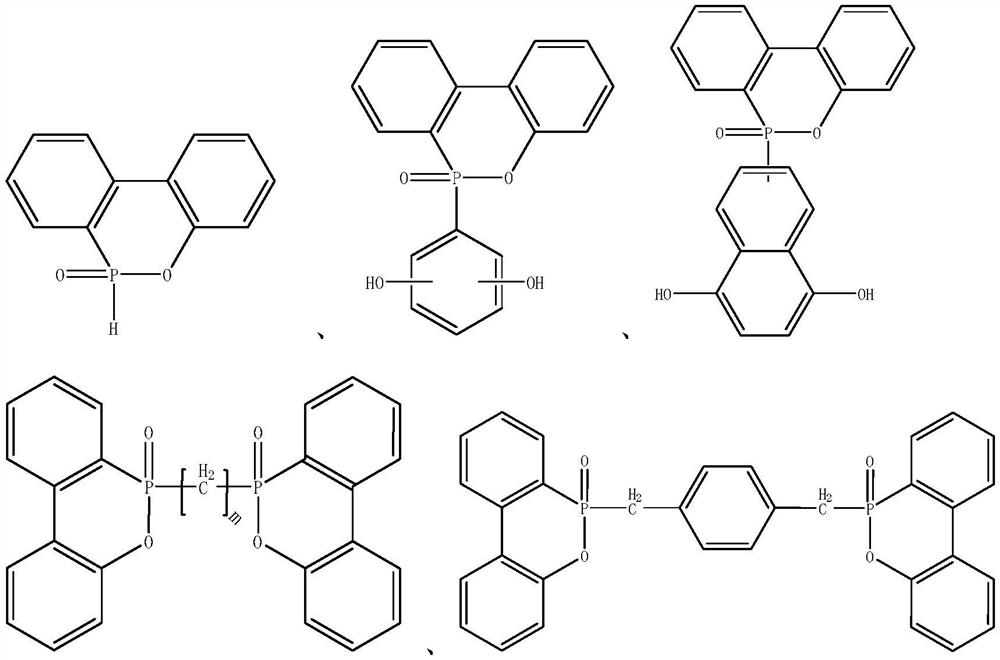

[0102] Nadic anhydride and phosphorus compounds React under the existence of initiator benzoyl peroxide, its temperature of reaction is 135 ℃, and the carbon-carbon double bond in the Nadic acid anhydride is reacted with the active hydrogen group in the phosphorus compound, obtains following structure A phosphorus-containing compound (I ).

[0103]

Synthetic example 2

[0104] Synthesis Example 2: Synthesis of Phosphorous Compound (I)

[0105] endomethyl nadic anhydride and phosphorus compounds React in the presence of initiator benzoyl peroxide, and its temperature of reaction is 135 ℃, and the carbon-carbon double bond in the Nadic acid anhydride is reacted with the active hydrogen group in the phosphorus compound, obtains following structure B phosphorus-containing compound (I ).

[0106]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com