Resistance measurement method for shielding layer of hydrogenerator stator bar

A stator bar, resistance value measurement technology, applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc. Measurement and other issues to achieve the effect of reducing the dielectric loss value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A method for measuring the resistance of the shielding layer of the stator bar of the hydroelectric generator:

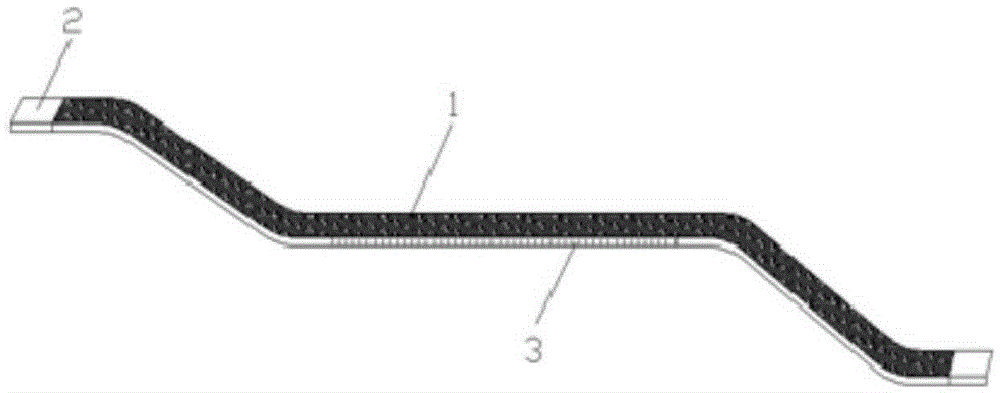

[0015] a. If figure 1 As shown, the stator bar is formed by transposition and insulation bonding of the electromagnetic wire to form the stator bar wire 1, and the lead wire 2 at both ends of the stator bar wire is removed from the insulation and welded into a whole;

[0016] b. Conduct copper leakage treatment at 3 intervals of 100mm at the transposition of the stator bar wire, that is, remove about 2mm2 of the electromagnetic wire insulation at the position to be treated, and leak the internal copper conductor;

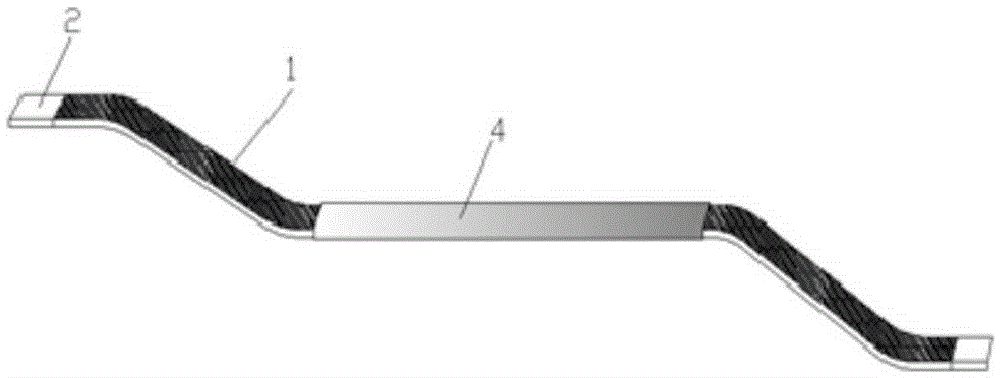

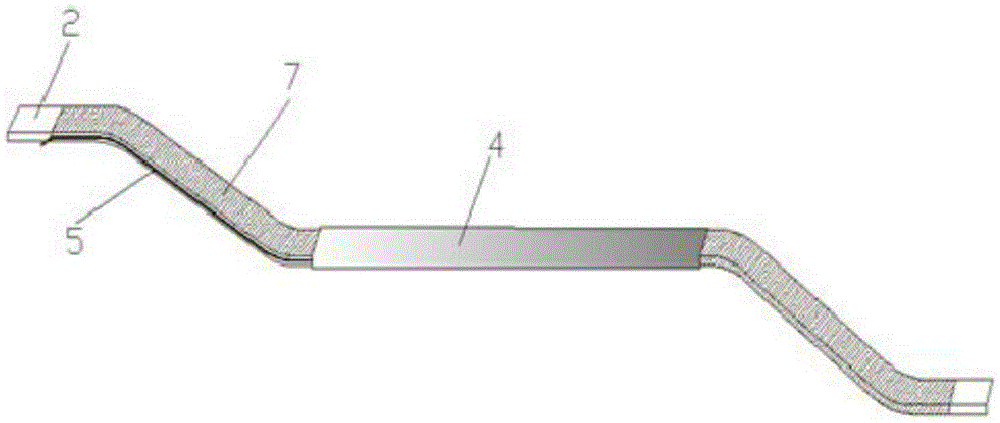

[0017] c. If figure 2 As shown, after the copper leakage treatment of the stator bar wire, the low-resistance anti-corona tape is half-folded on the stator bar wire 1, and the low-resistance anti-corona tape is wrapped to form the shielding layer 4, and the two ends of the shielding layer are lower than the stator wire 100mm in length at both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com