Epoxy resin composition, and prepreg and laminated board with epoxy resin composition

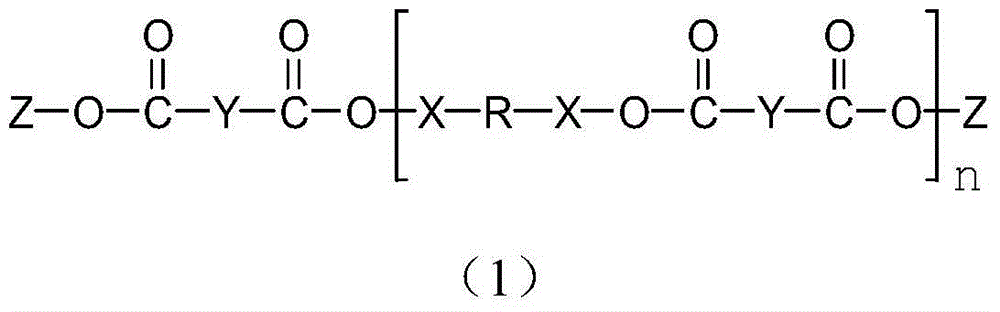

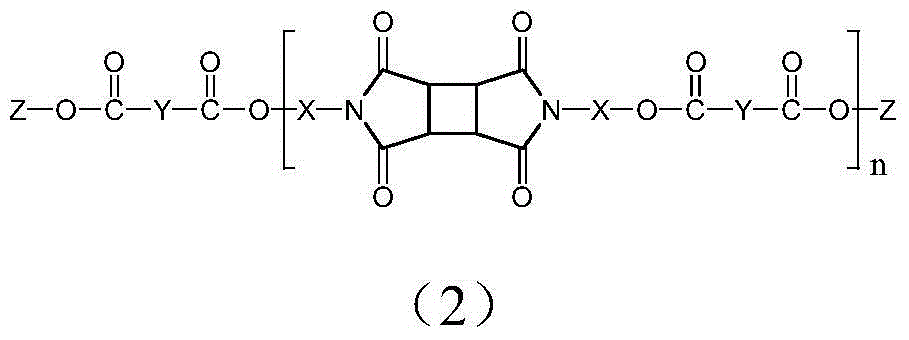

A technology of epoxy resin and composition, applied in the field of epoxy resin composition, prepreg, laminate and printed circuit board, which can solve the problem of low water absorption, moisture and heat resistance and dielectric properties, glass transition temperature problems such as low and low dielectric constant, to achieve the effect of good processability, good solubility, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

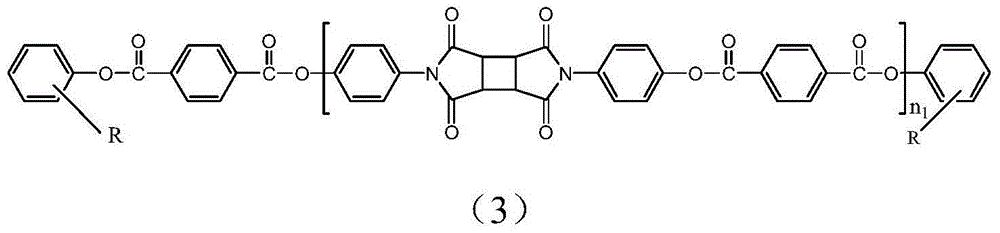

[0052] Preparation Example 1: Synthesis of imide-modified active ester curing agent A1

[0053] P-aminophenol 55g and 150g methyl ethyl ketone are added in the round-bottomed flask that has stirrer, thermometer, nitrogen inlet pipe and reflux condenser, water-bath heating accelerates its dissolution, and concentration is 10% (percentage by weight) cyclobutane Add 500 g of butanone solution of tetraformic dianhydride dropwise to the reactor, control the dropping speed so that it is added dropwise within 1 hour, continue to react for 2 hours at 40° C., evaporate butanone, add 80 parts by weight of DMF and 20 parts by weight of toluene part of mixed solvent, add 0.25 parts by weight of catalyst p-toluenesulfonic acid (P-TSA), and react at 110°C for 8h. After the reaction is completed, wash with water, filter, recrystallize, and dry in vacuo to obtain Structure of intermediates of hydroxyl compounds.

[0054] Add 38g of the intermediate obtained in the previous step in the round-...

preparation example 2

[0057] Preparation Example 2: Synthesis of imide-modified active ester curing agent A2

[0058] 8-amino-2-naphthol 80g and 250g butanone are added in the round-bottomed flask that has stirrer, thermometer, nitrogen inlet pipe and reflux condenser, and water-bath heating accelerates its dissolving, and concentration is 10% (percentage by weight) ) of butanone solution of cyclobutanetetracarboxylic dianhydride 500g was added dropwise to the reactor, the rate of addition was well controlled so that it was added dropwise within 1h, and the reaction was continued for 2h at 40°C, the butanone was distilled off, and DMF80 was added 20 parts by weight of toluene and 0.25 parts by weight of catalyst p-toluenesulfonic acid (P-TSA), reacted at 110°C for 8 hours, after the reaction was completed, washed with water, filtered, recrystallized, and dried in vacuo to obtain benzene-containing Intermediates for hydroxyl compounds with ring and imide structures.

[0059] Add 48g of the intermed...

preparation example 3

[0062] Preparation Example 3: Synthesis of imide-modified active ester curing agent A3

[0063] 8-amino-2-naphthol 80g and 250g butanone are added in the round-bottomed flask that has stirrer, thermometer, nitrogen inlet pipe and reflux condenser, and water-bath heating accelerates its dissolving, and concentration is 10% (percentage by weight) 550 g of butanone solution of pyromellitic dianhydride) was added dropwise to the reactor, and the rate of addition was well controlled so that it was added dropwise within 1 hour. The reaction was continued for 2 hours at 40° C., the butanone was distilled off, and 80 parts by weight of DMF was added. and a mixed solvent of 20 parts by weight of toluene, add 0.25 parts by weight of catalyst p-toluenesulfonic acid (P-TSA), react at 110°C for 8 hours, after the reaction is completed, wash with water, filter, recrystallize, and dry in vacuo to obtain Intermediates of hydroxyl compounds with imide structure.

[0064] Add 48g of the interm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com