Method for interweaving basalt fibers in asphalt mixture

A technology of basalt fiber and asphalt mixture, which is applied in the field of basalt fiber interweaving in asphalt mixture, can solve the problems of reaction, less water stability, and high production cost, and achieves improved low-temperature crack resistance, improved water stability, and reduced The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] First heat the SBS modified asphalt to a molten state in an oven at 180±5°C, and keep it warm for later use.

[0039] Preheat 10927.48g coarse and fine aggregates at 175±5°C for more than 4h.

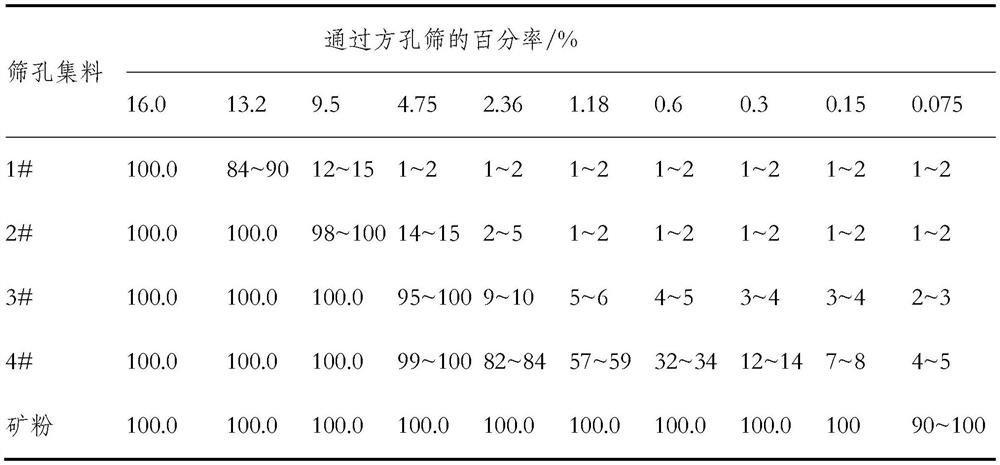

[0040] Heat the mixing pot of asphalt mixture to 185±5°C, first pre-heated 10927.48g coarse and fine aggregates (among which the mass of 1# material, 2# material, 3# material and 4# material are 4842.86g, 4594.51g respectively , 0.00g, 1490.11g) and 15.37g of chopped basalt fiber, 15.37g of lignin fiber and 15.37g of polyester fiber were mixed in a mixing pot for 95s;

[0041] Then add 760.58g of SBS modified asphalt for heat preservation and mix for 95-100s, and finally add 1490.11g of ore powder and mix for 95-100s to prepare the asphalt mixture mixed with basalt fiber, lignin fiber and polyester fiber. material.

Embodiment 2

[0043] First heat the SBS modified asphalt to a molten state in an oven at 180±5°C, and keep it warm for later use.

[0044] Preheat 10959.24g of coarse and fine aggregates at 175±5°C for more than 4 hours.

[0045] Heat the asphalt mixture mixing pot to 185±5°C, firstly preheat 10959.24g of coarse and fine aggregates (of which the mass of 1# material, 2# material, 3# material and 4# material are respectively 4856.94g, 4607.86g , 0.00g, 1494.44g) and 23.08g of chopped basalt fiber, 11.54g of lignin fiber and 11.54g of polyester fiber were mixed in the mixing pot for 95s, and then 737.26g of SBS modified asphalt for heat preservation was added and mixed Mix for 95-100 seconds, and finally add 1494.44 g of ore powder and mix for 95-100 seconds to prepare the asphalt mixture mixed with basalt fiber, lignin fiber and polyester fiber.

Embodiment 3

[0047]First heat the SBS modified asphalt to a molten state in an oven at 180±5°C, and keep it warm for later use.

[0048] Preheat 10935.50g of coarse and fine aggregates at 175±5°C for more than 4 hours.

[0049] Heat the asphalt mixture mixing pot to 185±5°C, firstly preheat 10935.50g of coarse and fine aggregates (of which the mass of 1# material, 2# material, 3# material and 4# material are respectively 4846.42g, 4597.88g , 0.00g, 1491.21g) and 18.43g of chopped basalt fiber, 9.22g of lignin fiber and 18.43g of polyester fiber were mixed in the mixing pot for 95s, and then 738.15g of SBS modified asphalt was added for heat preservation and mixed Mix for 95-100s, and finally add 1491.21g of ore powder and mix for 95-100s to prepare the asphalt mixture mixed with basalt fiber, lignin fiber and polyester fiber.

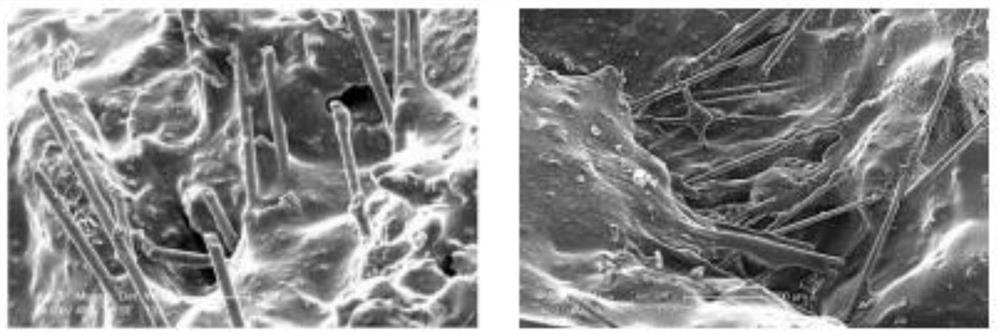

[0050] SEM images of the fiber-asphalt interface (such as figure 1 Shown), combined with a large number of fiber interweaving experiments, it can be seen that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com