Solid cosmetic composition having improved high-temperature stability and feeling of use, and method for preparing same

A cosmetic composition and high temperature stability technology, applied in cosmetic preparations, cosmetics, cosmetics and other directions, can solve problems such as heavy use feeling, achieve the effect of not heavy use feeling, improve freedom, and improve hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

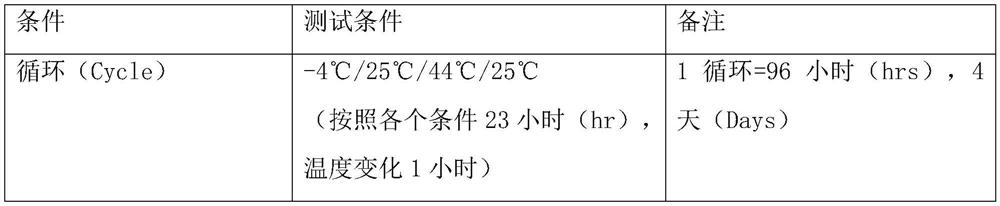

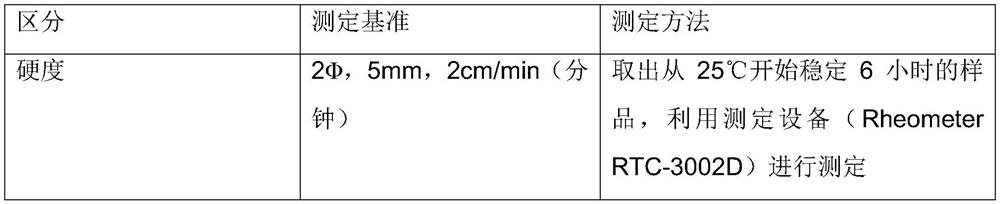

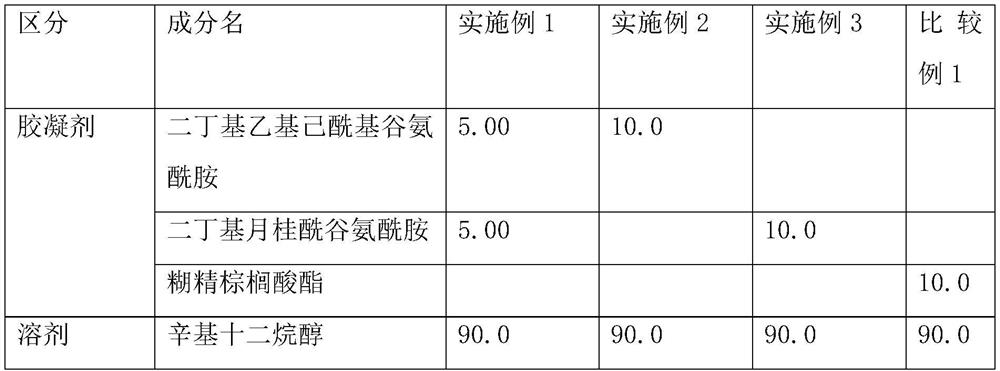

[0072] [Examples 1, 2, 3, Comparative Example 1]

[0073] The gelling agent mixtures of Examples 1, 2, 3 and Comparative Example 1 were prepared according to the components set forth in Table 3 below. The mixture is prepared by dissolving the solute and solvent at a ratio of 1:9 at a high temperature (90°C to 140°C).

[0074] 【table 3】

[0075]

[0076] Immediately after preparation according to the type of gelling agent dissolved in the fatty alcohol of Examples 1, 2, 3 and Comparative Example 1, the dissolution temperature, melting point and hardness of the mixture were confirmed, and the results are shown in Table 4 below.

[0077] 【Table 4】

[0078] distinguish Melting temperature melting point of the mixture hardness Example 1 Above 130℃ Above 100℃ more than 90 percent Example 2 130℃ Above 100℃ 90 Example 3 120℃ 75℃~80℃ 60 Comparative Example 1 90℃ 55℃~60℃ 40

[0079] From the results in Table 4, the dissolution...

Embodiment 3 and comparative example 2~3

[0081] According to the solvents described in Table 5 below, mixtures of Example 3 and Comparative Examples 2 to 3 were prepared. The mixture is prepared by dissolving the solute and solvent at a ratio of 1:9 at a high temperature (above 100°C).

[0082] 【table 5】

[0083] distinguish Ingredient name Example 3 Comparative Example 2 Comparative Example 3 gelling agent Dibutyllauroylglutamine 10.0 10.0 10.0 solvent Octyldodecanol 90.0 Ethylhexyl Palmitate 90.0 Cyclopentasiloxane 90.0

[0084] The ester oil of Comparative Example 2 and the silicone oil of Comparative Example 3 were prepared as solvents in addition to the fatty alcohol as the solvent of Example 3, and the dissolution temperature, melting point and hardness of the mixture were confirmed immediately after preparation, and the following The results are shown in Table 6.

[0085] 【Table 6】

[0086] distinguish Melting temperature meltin...

Embodiment 4~9

[0089] The mixtures of Examples 4-9 were prepared according to the solvent contents described in Table 7 below. The mixture is prepared by dissolving at a temperature above 100°C.

[0090] 【Table 7】

[0091]

[0092] The above-mentioned Examples 4 to 9 are for confirming the ratio of the gelling agent and the solvent most suitable for use in the formulation, and the melting point of the mixture according to each content of the solvent is shown in Table 8 below.

[0093] 【Table 8】

[0094]

[0095] Looking at the results in Table 8, the content ratio suitable for the formulation is as small as possible. In addition, considering the preparation process and the high temperature stability of the dosage form, the melting point is preferably in the range of 80°C to 90°C. From this, it was confirmed that the mixing ratio of the gelling agent and the solvent was the most suitable in Example 7 with the smallest content within a suitable range of the melting point.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com