A kind of high-temperature connecting agent and its connecting method for alumina ceramic connection

A kind of technology of alumina ceramics and connecting agent, which is applied in the field of ceramic materials, can solve the problems of reducing the high-temperature oxidation resistance and corrosion resistance of materials, the low temperature of connecting materials, and the limitation of high-temperature resistance of connecting test pieces, etc., and achieve high interface bonding strength , Improve the interface bonding strength and ensure the effect of high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

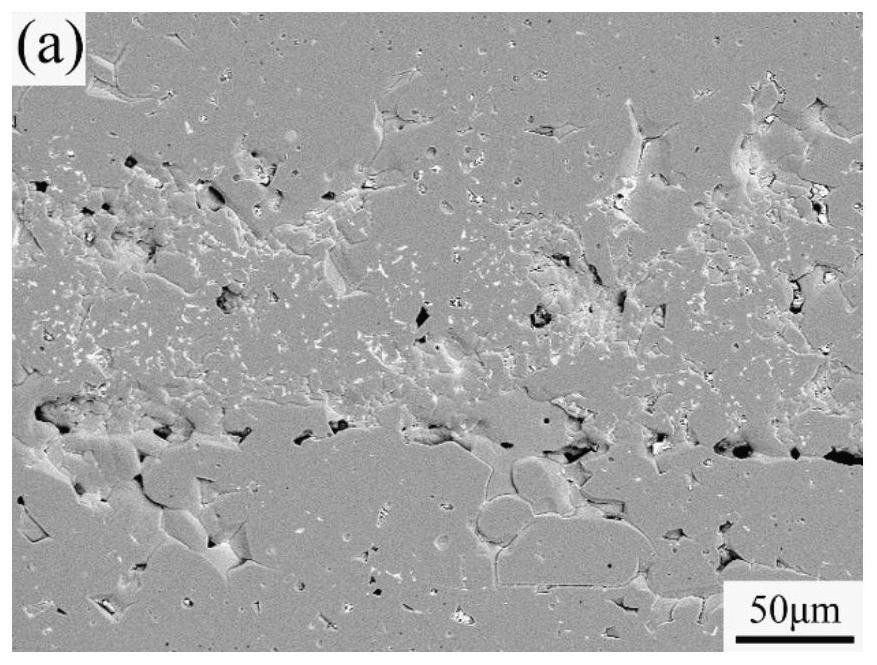

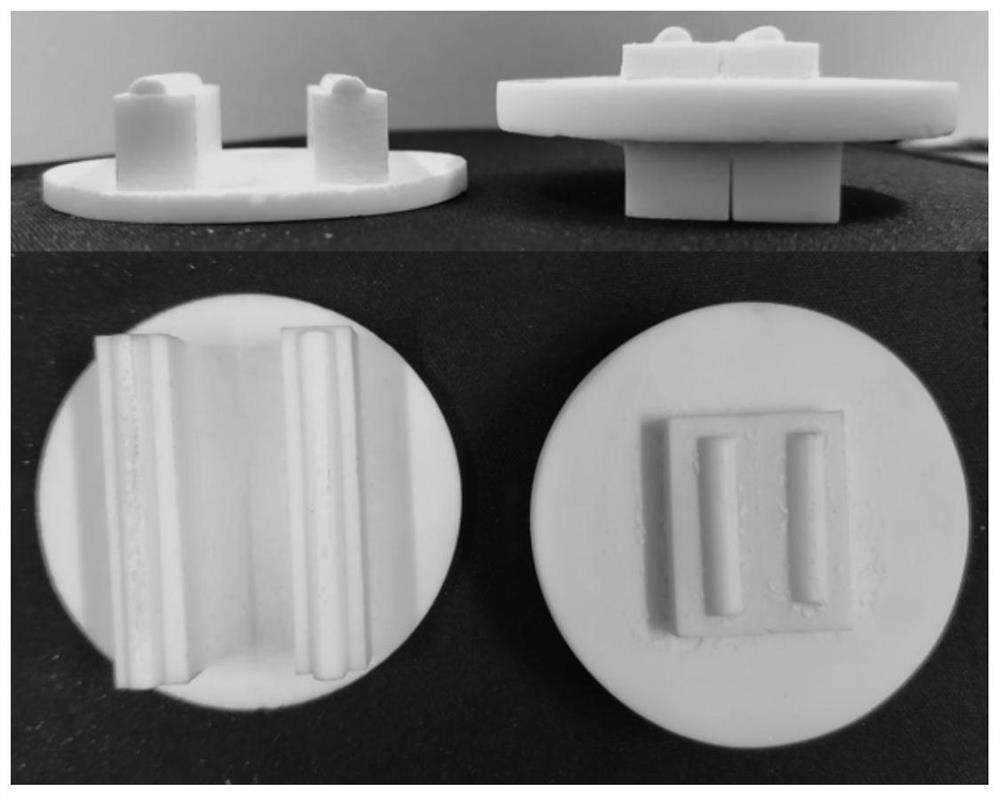

Image

Examples

Embodiment 1

[0030] The present embodiment provides a high-temperature connecting agent for connecting alumina ceramics and a connecting method thereof, which specifically includes the following steps:

[0031] Step 1: Take Al with an average particle size of 0.1 μm and a chemical purity greater than 99.0% 2 O 3 Powder, TiO 2 Powder and Ta 2 O 5 Powder, according to the mass fraction of 97% Al 2 O 3 Powder, 3% TiO 2 Powder ball milling and mixing; ball milling method is wet roller ball milling, ethanol is the ball milling medium, yttrium-stabilized zirconia balls are the grinding balls, and the ball milling mixing time is 8h; the dried mixed powder is uniformly mixed with 1% by mass PVA, And add an appropriate amount of alcohol to ultrasonically disperse to obtain a suspension with a concentration of 0.4g / ml;

[0032] Step 2: Evenly coat the suspension obtained in Step 1 on the surface of the alumina ceramic block to be connected, and press the alumina ceramic surface to make good c...

Embodiment 2

[0035] The present embodiment provides a high-temperature connecting agent for connecting alumina ceramics and a connecting method thereof, which specifically includes the following steps:

[0036] Step 1: Take Al with an average particle size of 0.1 μm and a chemical purity greater than 99.0% 2 O 3 Powder, TiO 2 Powder and Ta 2 O 5 Powder, according to the mass fraction of 97% Al 2 O 3 Powder, 3% TiO 2Powder ball milling and mixing; the ball milling method is wet roller ball milling, ethanol is the ball milling medium, yttrium-stabilized zirconia balls are the grinding balls, and the ball milling mixing time is 24h; the dried mixed powder is evenly mixed with 1% by mass PVA, And add an appropriate amount of alcohol to ultrasonically disperse to obtain a suspension with a concentration of 0.2g / ml;

[0037] Step 2: Evenly coat the suspension obtained in Step 1 on the surface of the alumina ceramic block to be connected, and press the alumina ceramic surface to make good ...

Embodiment 3

[0040] The present embodiment provides a high-temperature connecting agent for connecting alumina ceramics and a connecting method thereof, which specifically includes the following steps:

[0041] Step 1: Take Al with an average particle size of 0.1 μm and a chemical purity greater than 99.0% 2 O 3 Powder, TiO 2 Powder and Ta 2 O 5 Powder, according to the mass fraction of 97% Al 2 O 3 Powder, 3% TiO 2 Powder ball milling and mixing; the ball milling method is wet roller ball milling, ethanol is the ball milling medium, yttrium stabilized zirconia balls are the grinding balls, and the ball milling mixing time is 16h; the dried mixed powder is evenly mixed with 1% by mass PVA, And add an appropriate amount of alcohol to ultrasonically disperse to obtain a suspension with a concentration of 0.8g / ml;

[0042] Step 2: Evenly coat the suspension obtained in Step 1 on the surface of the alumina ceramic block to be connected, and press the alumina ceramic surface to make good...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com