Electrolyte for lithium secondary battery and lithium secondary battery comprising same

A lithium secondary battery and electrolyte technology, applied in the field of electrolytes for lithium secondary batteries and lithium secondary batteries including the same, can solve the problems of electrolyte consumption, poor safety, high temperature performance deterioration, etc., and achieve improved cycle life characteristics, the effect of ensuring high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0138] Hereinafter, examples of the present invention and comparative examples are described. However, these examples should not be construed as limiting the scope of the present invention in any sense.

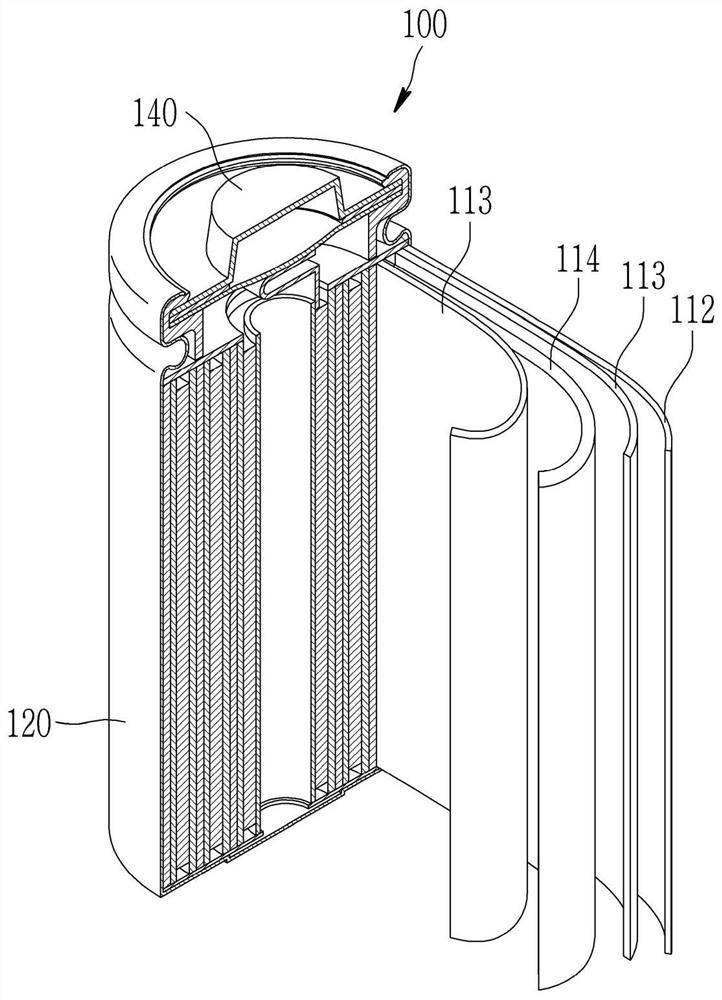

[0139] Manufacture of lithium secondary battery cells

preparation Embodiment 1

[0140] Preparation Example 1: Synthesis of Compound 1-1

[0141] [Compound 1-1]

[0142]

[0143] Trimethylsilylsulfonyl chloride (38.47.53 g, 0.204 mol) was added dropwise to 1,4-divinyl-1,1,4,4,-tetramethyl-1 under cooling , 4-disilazane (19.94 g, 0.101 mol) for 2 hours. Subsequently, the reaction mixture was kept at room temperature (20°C) for 15 hours. Then, the reaction mixture was heated to 110° C. and kept at the same temperature for 5 hours, and at the same time, the reaction product was distilled to remove trimethylsilyl chloride produced therein as a by-product. The resulting product was cooled to room temperature, and then, the remaining reaction product was distilled under vacuum through a short Vigreux column.

[0144] The resulting product was redistilled at a fractionation temperature of 184°C to 188°C / 0.05 Torr to obtain the product as a colorless oil (21.78 g, 60.4%). The corresponding materials are very sensitive to moisture.

[0145] 1H NMR (400 MHz,...

preparation Embodiment 2

[0148] Preparation Example 2: Synthesis of Compound 1-2

[0149] [Compound 1-2]

[0150]

[0151] A mixture of 1,2-bis(chlorodimethylsilyl)ethane (21.53 g, 0.1 mol) and methanesulfonic acid (19.22 g, 0.2 mol) was heated to 65°C for 30 minutes and kept at the same temperature About 1 hour until the reaction with HCl is complete. Subsequently, the temperature of the reaction mixture was raised to 120°C and then kept for 24 hours. The product was cooled to room temperature and distilled under vacuum through Vigreux column distillation. Here, the distillation condenser is kept warm to prevent plugging of the column due to recrystallization of the product therein. The product was treated by partitioning at 162°C to 164°C / 0.05 to obtain the product as a colorless oil (23.19 g, 69.3%).

[0152] 1H NMR (400 MHz, CDCl3), δ 0.33 (s, 12H), 0.75 (s, 4H), 2.93 (s, 6H).

[0153] 13C NMR (100 MHz, CDCl3), delta-1.83(s), 7.45(s), 40.08(s).

[0154] 29Si NMR (80MHz, CDCl3), δ32.39(s) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com