A kind of methane catalytic combustion catalyst and preparation method thereof

A methane catalytic combustion and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low catalytic activity of catalysts and poor high temperature stability, so as to improve catalytic activity and high temperature Stability, the effect of maintaining high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

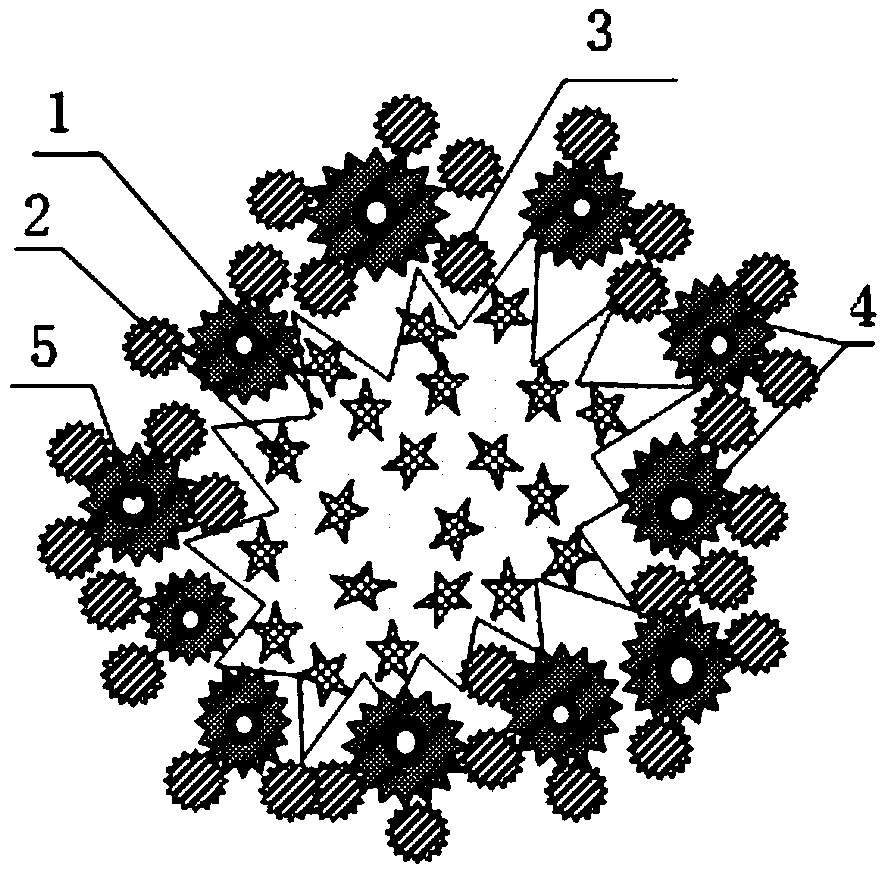

Image

Examples

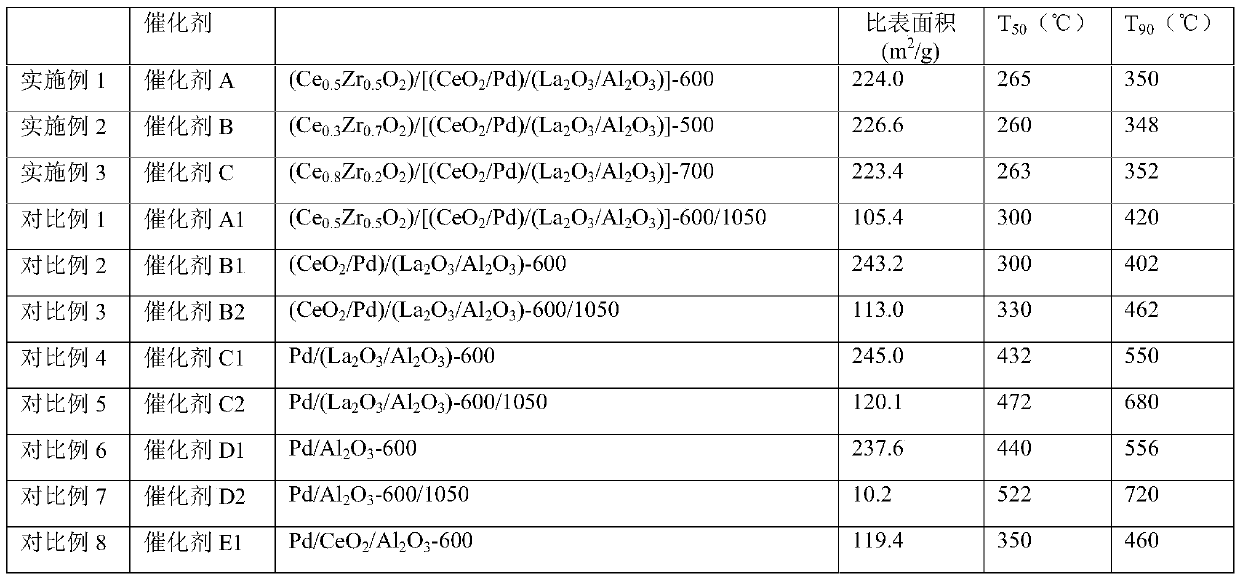

Embodiment 1

[0043] The preparation method of the methane catalytic combustion catalyst provided by the present embodiment comprises the following steps:

[0044] (1) Preparation of carrier

[0045] Weigh 18.7g La(NO 3 ) 3 ·6H 2 O was dissolved in 160mL deionized water to make a solution, and then weighed 200g of 90 mesh γ-Al 2 o 3 , its water absorption rate was measured to be 80%, and the above solution was impregnated with γ-Al by equal impregnation method. 2 o 3 , and then collect the solid phase, which is dried at 150°C for 3h and calcined at 600°C for 4h, which is the alumina carrier modified by lanthanum oxide (La 2 o 3 / Al 2 o 3 ), the mass ratio of lanthanum oxide and aluminum oxide in the above-mentioned carrier is 6:100;

[0046] (2) Preparation of ceria-coated active component solution

[0047] Get 2g mean particle diameter and be the noble metal palladium particle of 2 nanometers, and be dissolved in 50mL tetrahydrofuran solution, obtain solution A after adding 2.05...

Embodiment 2

[0057] The preparation method of the methane catalytic combustion catalyst provided by the present embodiment comprises the following steps:

[0058] (1) Preparation of carrier

[0059] Weigh 16.7g La(NO 3 ) 3 ·6H 2 O was dissolved in 160mL deionized water to make a solution, and then weighed 200g of κ-Al with a mesh number of 100 2 o 3 , the water absorption rate was measured to be 80%, and the above solution was impregnated with κ-Al 2 o 3 , and then collect the solid phase, which is dried at 140°C for 4h and calcined at 900°C for 3h, which is the alumina carrier modified by lanthanum oxide (La 2 o 3 / Al 2 o 3 ), the mass ratio of lanthanum oxide and aluminum oxide in the above-mentioned carrier is 3:100;

[0060] (2) Preparation of ceria-coated active component solution

[0061] Get 2g of noble metal platinum particles with an average particle diameter of 3 nanometers, and dissolve it in 50mL of tetrahydrofuran solution, add 1.41g of mercaptosuccinic acid to the ...

Embodiment 3

[0071] The preparation method of the methane catalytic combustion catalyst provided by the present embodiment comprises the following steps:

[0072] (1) Preparation of carrier

[0073] Weigh 18.7g La(NO 3 ) 3 ·6H 2 O was dissolved in 160mL deionized water to make a solution, and then weighed 200g of 80 mesh θ-Al 2 o 3 , its water absorption rate was measured to be 80%, and the above solution was impregnated with θ-Al by equal impregnation method. 2 o 3 , and then collect the solid phase, which is dried at 160°C for 2h and calcined at 500°C for 5h, which is the alumina carrier modified by lanthanum oxide (La 2 o 3 / Al 2 o 3 ), the mass ratio of lanthanum oxide and aluminum oxide in the above-mentioned carrier is 10:100;

[0074] (2) Preparation of ceria-coated active component solution

[0075] Take 2g of noble metal indium particles with an average particle diameter of 1 nanometer, and dissolve it in 50mL of tetrahydrofuran solution, add 1.39g of mercaptocaproic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com