PTC composite material containing polyethylene, carbon black and conductive modified graphene and preparation method

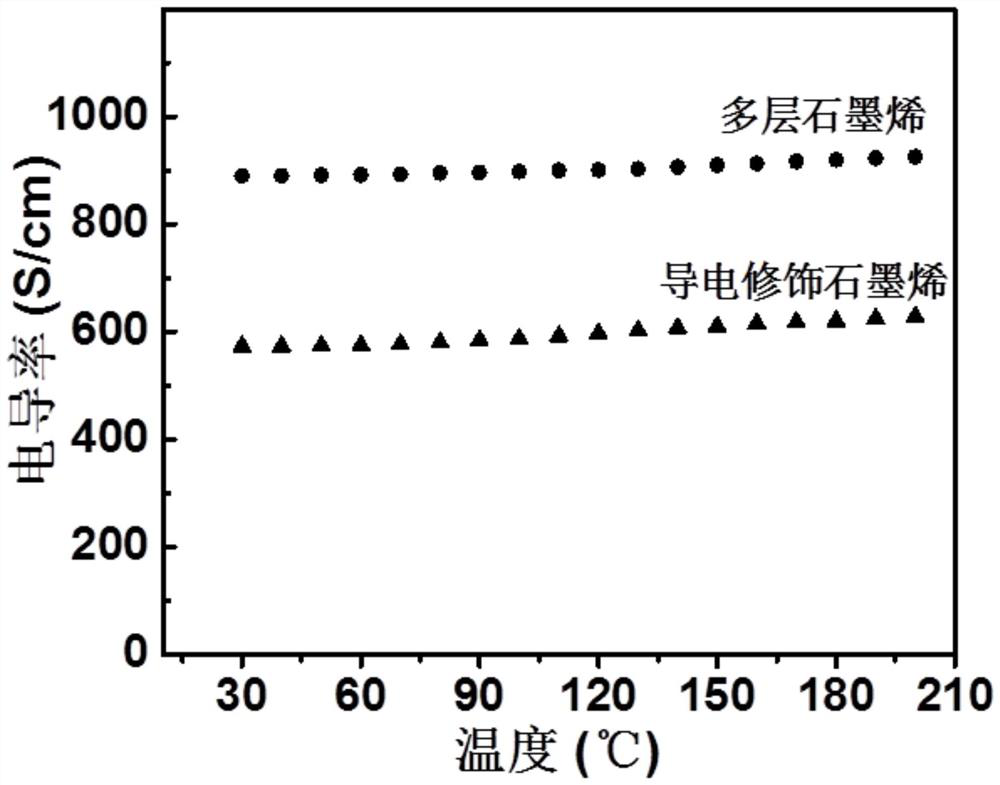

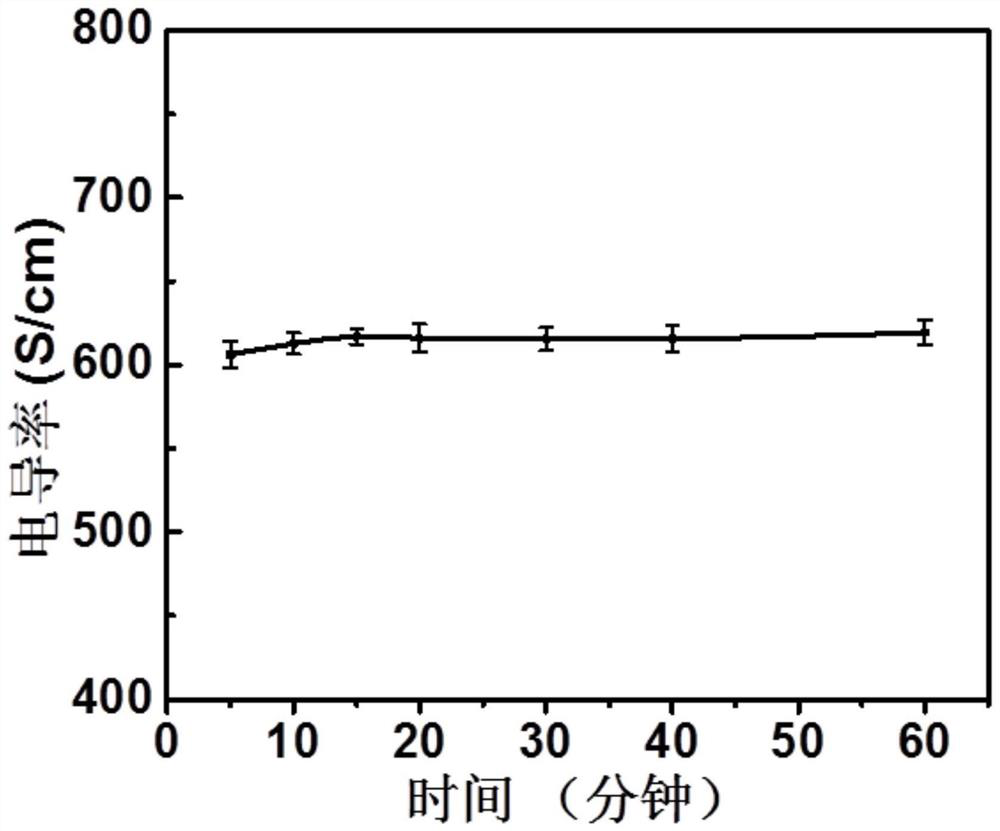

A composite material and polyethylene technology, applied in the field of functional polymer materials, can solve the problems of low electrical conductivity, complicated manufacturing method, and reduced graphene electrical conductivity, and achieve low room temperature resistivity, low NTC strength, and reduced room temperature resistance. The effect of rate and filler amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of conductive modified graphene comprises the following steps:

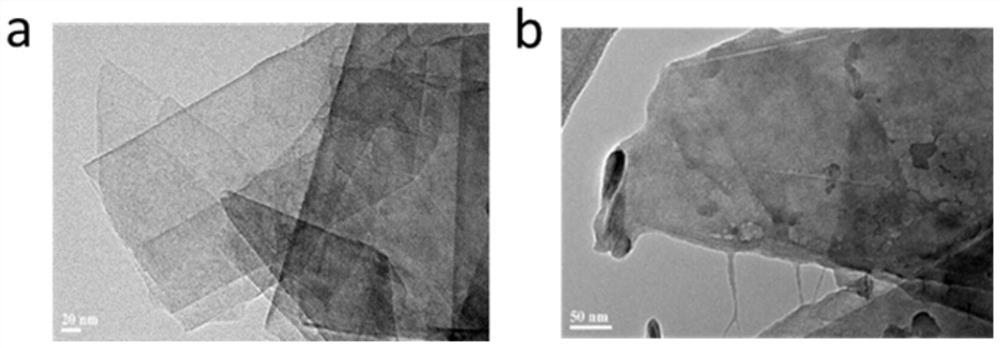

[0043] 1 g of sodium polystyrene sulfonate and 5 g of multi-layer graphene (with a thickness of about 5 nm and a diameter of 7 to 15 μm) were added to 950 ml of a 1M sulfuric acid solution, and ultrasonically stirred for 1 h to obtain a mixed system A.

[0044] 0.5 g of 3,4-ethylenedioxythiophene monomer was added to mixed system A, and ultrasonic stirring was continued for 1 h under ice bath conditions to obtain mixed system B.

[0045] Initiating system C was obtained by dissolving 0.8 g of ammonium persulfate and 12 mg of ferric chloride in 50 ml of 1 M sulfuric acid solution.

[0046]The initiation system C was added dropwise to the mixed system B for 30 min to initiate a polymerization reaction, which was stirred for 24 h in an ice-water bath. The product was filtered, washed with deionized water and ethanol for several times, and freeze-dried to obtain conductive modified grap...

Embodiment 2

[0052] The preparation method of conductive modified graphene comprises the following steps:

[0053] Add 1 g of sodium polystyrene sulfonate and 20 g of multi-layer graphene (with a thickness of about 5 nm and a diameter of 5-17 μm) into 950 ml of 0.1 M hydrochloric acid solution, and ultrasonically stirred for 1 h to obtain a mixed system A.

[0054] 1 g of 3,4-ethylenedioxythiophene monomer was added to mixed system A, and ultrasonic stirring was continued for 1 h under ice bath conditions to obtain mixed system B.

[0055] Initiating system C was obtained by dissolving 1.9 g of ammonium persulfate and 14 mg of ferric chloride in 50 ml of 0.1 M hydrochloric acid solution.

[0056] The initiation system C was added dropwise to the mixed system B for 30 min to initiate the polymerization reaction, and the reaction was stirred under an ice bath for 12 h. The product was filtered, washed with deionized water and ethanol for several times, and freeze-dried to obtain conductive ...

Embodiment 3

[0060] The preparation method of conductive modified graphene comprises the following steps:

[0061] 3g of sodium dodecyl sulfate and 6g of multi-layer graphene (with a thickness of about 5nm and a diameter of 7-15μm) were added to 950ml of 0.5M sulfuric acid solution, and ultrasonically stirred for 1h to obtain a mixed system A.

[0062] 1 g of 3,4-ethylenedioxythiophene monomer was added to mixed system A, and ultrasonic stirring was continued for 1 h under ice bath conditions to obtain mixed system B.

[0063] Initiating system C was obtained by dissolving 2.4 g of ammonium persulfate and 8 mg of ferric chloride in 50 ml of 0.5 M sulfuric acid solution.

[0064] The initiation system C was added dropwise to the mixed system B for 30 min to initiate a polymerization reaction, which was stirred for 36 h under an ice bath. The product was filtered, washed with deionized water and ethanol for several times, and freeze-dried to obtain conductive modified graphene.

[0065] A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com