Method for preparing agni electrical contact material based on foaming infiltration process and product thereof

An electrical contact material and infiltration technology, applied in metal processing equipment, contacts, circuits, etc., can solve the problems of low powder strength, skeleton collapse, and inability to form, achieving low body resistance, stable temperature rise, and improved The effect of electric life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

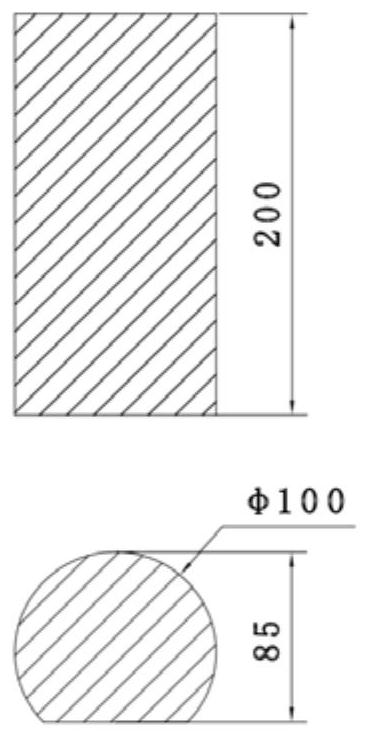

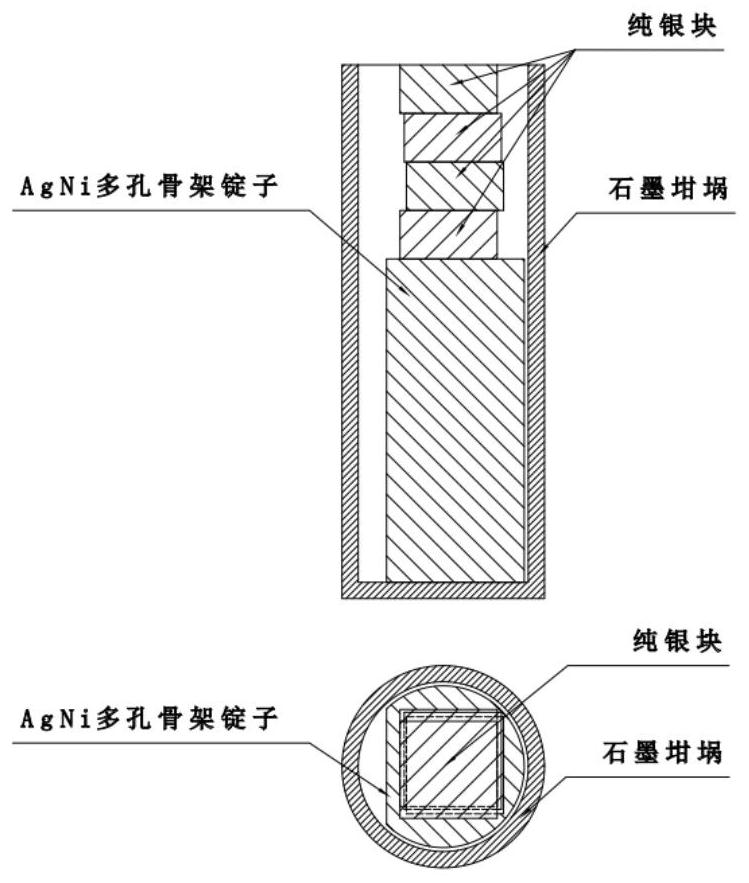

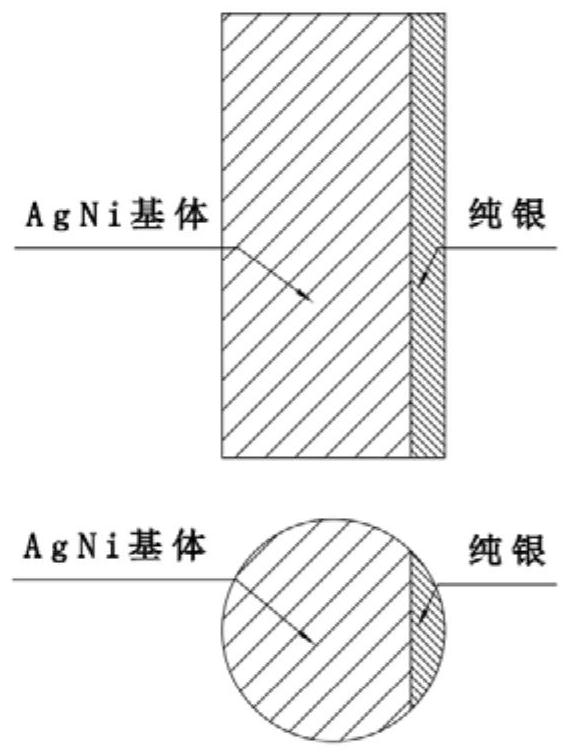

[0052] Called 5KG AGNI45 mixed powder, add 5WT % of ammonium carbonate solution, 5WT % ammonium carbonate solution each 500g and stir well. Granules;

[0053] The sieving powder is installed in the graphite boat, transferred to the vacuum oven to heat it to 200 ° C for 60 minutes, and then transfer the foaming powder and graphite boat to the hydrogen atmosphere to burn the sintering and burn 800 ° C for 30 minutes. It

[0054] Mix the sintering powder and heat the powder on the mixer. At the same time, spray 10WT % paraffin-gasoline solution 0.5kg, wrap all the powder, heat up the gasoline in the pink body;

[0055] The powder -loading boats that are wrapped in burn -in -law wrapped in the hydrogen atmosphere for sintering treatment. The sintering process is 400 ° C, 120 minutes, 600 ° C, 120 minutes, 800 ° C, 120 minutes, 1000 ° C, 60 minutes, and the cooling and crushing after sintering have been cooled and crushed. 100 mesh screen, obtain high -strength polychole prefabricated ...

Embodiment 2

[0061] Called 10kg Agni45 mixed powder, add 5WT % dual oxygen solution 1kg and stir well. After the stirred powder sieved with 100 mesh stainless steel to obtain the AGNI powder particles wrapped in the foaming agent;

[0062] The sieving powder is installed in the graphite boat, transferred to the vacuum oven to heated to 60 ° C for 30 minutes, and then transfer the foaming powder and graphite boat to the ammonia decomposition atmosphere of the sintering furnace of 500 ° C, heat preservation 120 120 minute;

[0063] Mix the sintering powder and heat the powder on the mixer. At the same time, spray 1WT % paraffin-gasoline solution 2kg, wrap all the powder, heat the stirring powder in the pink body, dry;

[0064] The powder -loading boats that are wrapped in burn -in -law wrapping are sintering in the atmosphere of ammonia. The sintering process is 500 ° C, 60 minutes, 700 ° C, 60 minutes, 900 ° C, 60 minutes, 1100 ° C, 60 minutes. After 50 mesh screens, obtain a high -strength pol...

Embodiment 3

[0069] Called 5KG AGNI40 mixed powder, add 5WT % ammonium oxalized ammonium oxalate solution, 5WT % ammonium hydrogen ammonium hydrogen ammonium solution and mix well. Granules;

[0070] The sieving powder is installed in the graphite boat, transferred to the vacuum oven to heated to 100 ° C for 60 minutes, and then transfer the foaming powder and graphite boat to the vacuum sintering furnace to burn for 600 ° C for 60 minutes;

[0071] Mix the sintering powder and heat the powder on the mixer. At the same time, spray 4 % paraffin-gasoline solution 0.5kg, wrap all the powder, heat the stirring powder in the pink body;

[0072] The powder -loading boats that are wrapped in burn -in -law wrapped in in the vacuum atmosphere are sintering. The sintering process is 450 ° C, 90 minutes, 650 ° C, 90 minutes, 850 ° C, 90 minutes, 1050 ° C, 90 minutes, and the cooling after sintering is broken and crushed too much too much 80 -mesh screen, obtain high -strength polychide prefabricated AGNI...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com