Method for preparing copper-based electrical contact material based on foaming infiltration process and product thereof

An electric contact material, copper-based technology, applied in the direction of metal processing equipment, contacts, circuits, etc., can solve the problems of difficult crushing process, landslide, bursting, etc., to ensure the performance of anti-arc burning and anti-mechanical wear, The effect of stabilizing the temperature rise of the contact and increasing the pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

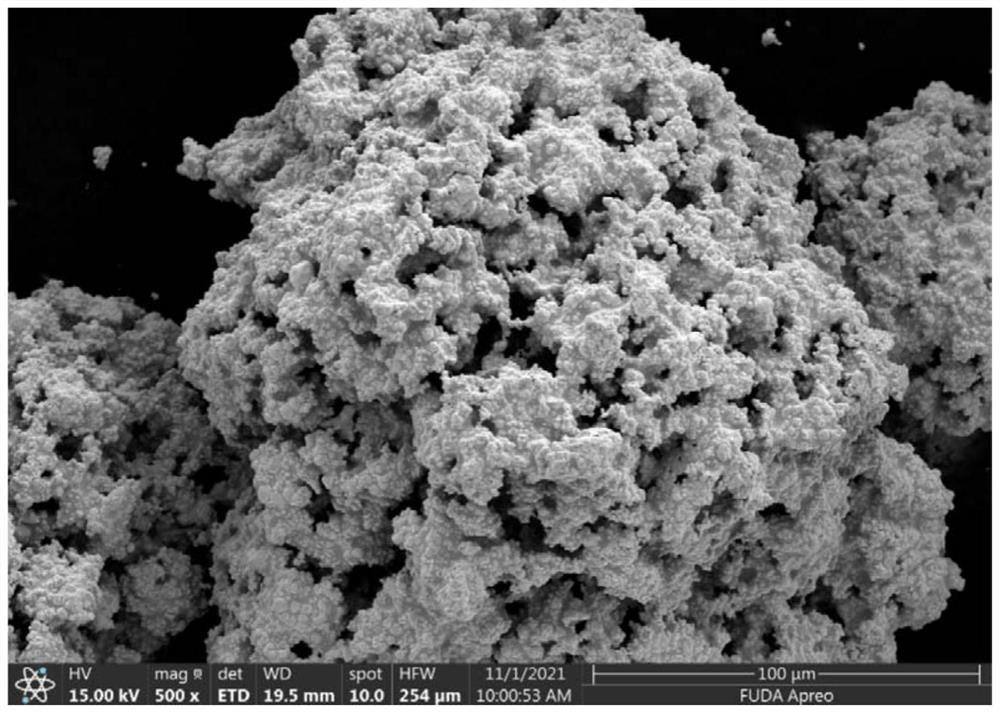

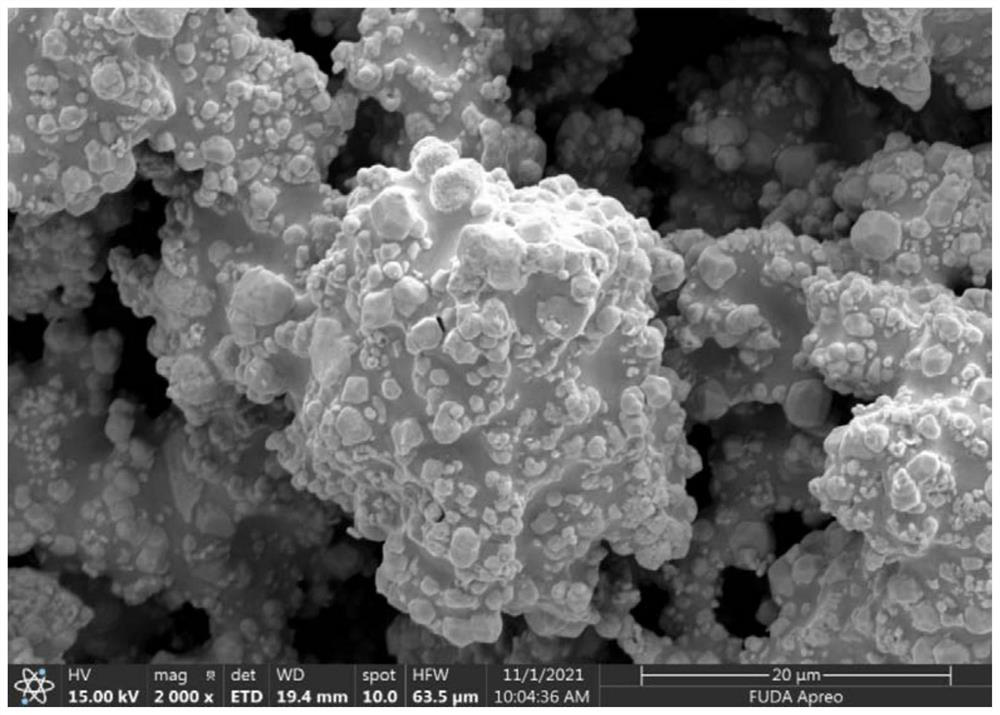

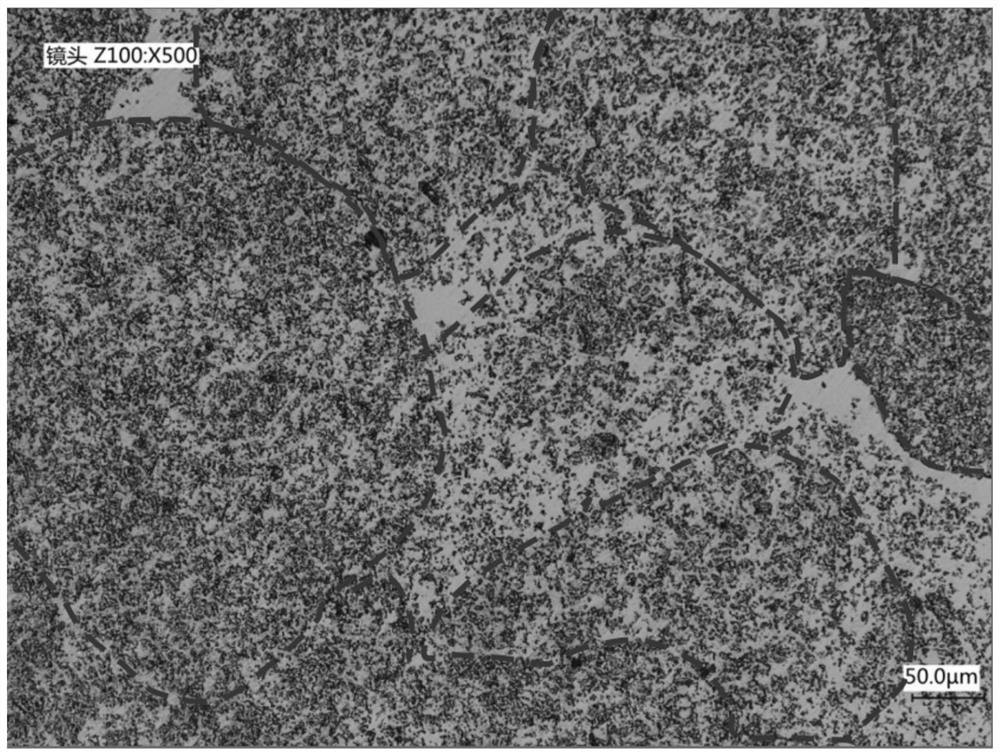

[0044] Weigh 5kg CuW50 mixed powder, add 50g each of 5wt% ammonium bicarbonate solution and 5wt% ammonium carbonate solution respectively and stir evenly, the stirred powder is sieved with a 300 mesh stainless steel sieve to obtain CuW powder wrapped by a foaming agent particles;

[0045] The sieved powder was loaded into a graphite boat, transferred to a vacuum oven and heated to 200°C for 60 minutes, and then the foamed powder and graphite boat were transferred to a hydrogen atmosphere sintering furnace for sintering at 800°C and kept for 30 minutes. ;

[0046] Stir the sintered-strengthened powder in a stirrer and heat the powder, spray 0.5kg of a 10wt% paraffin-gasoline solution at the same time, wrap the powder completely, and heat and stir until the gasoline in the powder is dried;

[0047] The powder wrapped with calcined paraffin was loaded into a boat and sintered in a hydrogen atmosphere. The sintering process was 400°C, 120 minutes, 600°C, 120 minutes, 800°C, 120 m...

Embodiment 2

[0051] Weigh 5kg of CuW40 mixed powder, add 2wt% ammonium oxalate solution, 2wt% ammonium hydrogen oxalate solution, 2wt% ammonium bicarbonate solution, 2wt% ammonium carbonate solution, 100g each and stir evenly, the stirred powder is sieved with 200 mesh stainless steel Sieve to obtain CuW powder particles wrapped by foaming agent;

[0052] The sieved powder is loaded into a graphite boat, transferred to a vacuum oven and heated to 150°C for 50 minutes, and then the foamed powder and graphite boat are transferred to an ammonia decomposition furnace for sintering at 700°C and kept for 50 minutes;

[0053] Stir the sintered-strengthened powder in a stirrer and heat the powder, spray 0.6 kg of 3% paraffin-gasoline solution at the same time, wrap the powder completely, and heat and stir until the gasoline in the powder is dried;

[0054] The powder wrapped with calcined paraffin was loaded into a boat and sintered in a hydrogen atmosphere. The sintering process was 450°C, 60 min...

Embodiment 3

[0058] Weigh 10kg CuMo32 mixed powder, add 2wt% ammonium oxalate solution, 2wt% ammonium hydrogen oxalate solution, 4wt% ammonium bicarbonate solution, 4wt% ammonium carbonate solution 200g and stir evenly, the stirred powder is sieved with a 120 mesh stainless steel sieve to obtain CuMo powder particles wrapped by the foaming agent;

[0059] The sieved powder is loaded into a stainless steel boat, transferred to a vacuum oven and heated to 120°C for 40 minutes, and then the foamed powder and stainless boat are transferred to a vacuum sintering furnace for sintering at 750°C and kept for 45 minutes;

[0060] Stir the sintered-strengthened powder in a stirrer and heat the powder, spray 0.5kg of 8% paraffin-gasoline solution at the same time, wrap all the powder, and heat and stir until the gasoline in the powder is dried;

[0061] The powder packed corundum boat wrapped in calcined paraffin was sintered in a hydrogen atmosphere. The sintering process was 500°C, 120 minutes, 700...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com