Filtrate loss reducer for water-based drilling fluid and preparation method of filtrate loss reducer

A technology of water-based drilling fluid and fluid loss control agent, which is applied in the field of drilling fluid, can solve the problems of hydration effect, viscosity reduction, side effects of shear force, unfavorable rheological adjustment, high polymer dosage, etc., to achieve good fluid loss control Ability, excellent temperature resistance, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

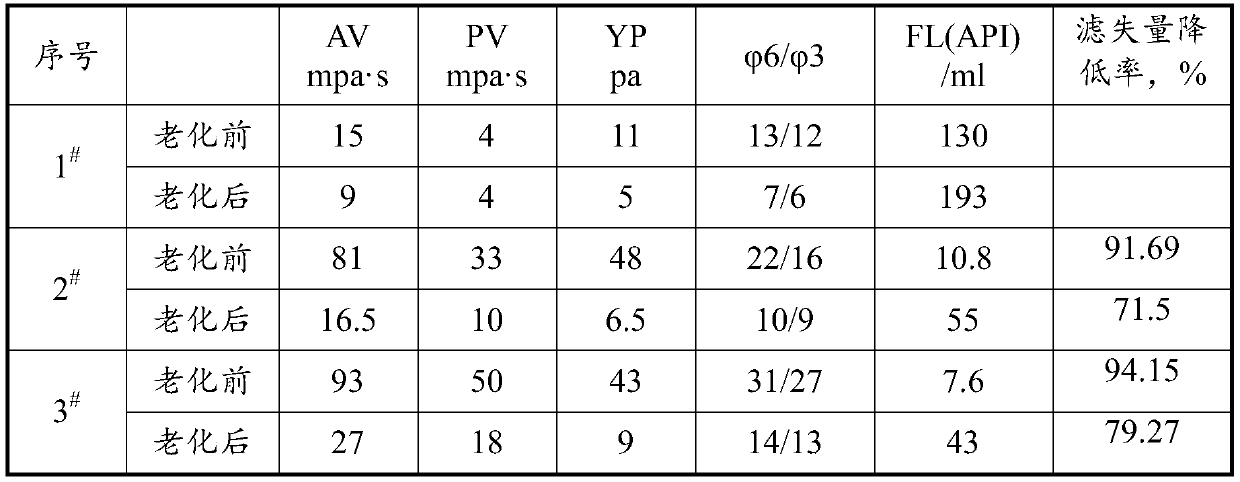

Embodiment 1

[0051] A fluid loss control agent for drilling fluids, in parts by weight, comprising: 20 parts of acrylamide; 6 parts of 2-acrylamido-2-methylpropanesulfonic acid, and methacryloyl propyl trimethyl chloride 5 parts of ammonium, 3 parts of sodium formate, 0.6 parts of sodium hydroxide, 0.04 parts of ammonium persulfate, 80: 6 parts of span, 20: 0.3 parts of span, 40 parts of water, 20 parts of white oil.

[0052] It is prepared by the following steps: under the condition of normal temperature and 25°C, the above-mentioned parts by weight of water, acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, methacrylamidotrimethyl Base ammonium chloride, sodium formate, sodium hydroxide, and Span 20 are mixed to prepare the water phase, and white oil and Span 80 are mixed to prepare the oil phase; the water phase and the oil phase are fully mixed to obtain the emulsion base liquid; the emulsion is placed in the reaction After filling the kettle with nitrogen, add initiator and react at...

Embodiment 2

[0072] A fluid loss reducer for drilling fluids, in parts by weight, comprising: 18 parts of acrylamide; 5 parts of 2-acrylamido-2-methylpropanesulfonic acid; methacryloyl propyl trimethyl chloride 4 parts of ammonium, 3 parts of sodium formate, 0.6 parts of sodium hydroxide, 0.04 parts of ammonium persulfate, 80: 5 parts of span, 20: 0.25 parts of span, 40 parts of water, 24 parts of white oil.

[0073] It is prepared by the following steps: under the condition of normal temperature and 25°C, the above-mentioned parts by weight of water, acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, methacrylamidotrimethyl Base ammonium chloride, sodium formate, sodium hydroxide, and Span 20 are mixed to prepare an aqueous phase,

[0074] And mixing white oil and Span 80 to prepare an oil phase;

[0075] Fully mix the water phase and the oil phase to obtain an emulsion base liquid; place the emulsion in a reactor, add an initiator after filling with nitrogen, and react at a constant temper...

Embodiment 3

[0091] A fluid loss reducer for drilling fluids, in parts by weight, comprising: 18 parts of acrylamide; 4.8 parts of 2-acrylamido-2-methylpropanesulfonic acid, methacryloyl propyl trimethyl chloride 4 parts of ammonium, 3 parts of sodium formate, 0.6 parts of sodium hydroxide, 0.04 parts of ammonium persulfate, 80: 4.5 parts of Span, 20: 0.25 parts of Span, 40 parts of water, 24 parts of white oil.

[0092] It is prepared by the following steps: under the condition of normal temperature and 25°C, the above-mentioned parts by weight of water, acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, and methacrylamido trimethyl are sequentially added to the reaction kettle. Base ammonium chloride, sodium formate, sodium hydroxide, and Span 20 are mixed to prepare an aqueous phase,

[0093] And mixing white oil and Span 80 to prepare an oil phase;

[0094] Fully mix the water phase and the oil phase to obtain an emulsion base liquid; place the emulsion in a reactor, add an initiator aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com