Neodymium iron boron material and preparation method and application thereof

A technology of permanent magnet material and content, applied in magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve problems such as poor consistency and deterioration of magnet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

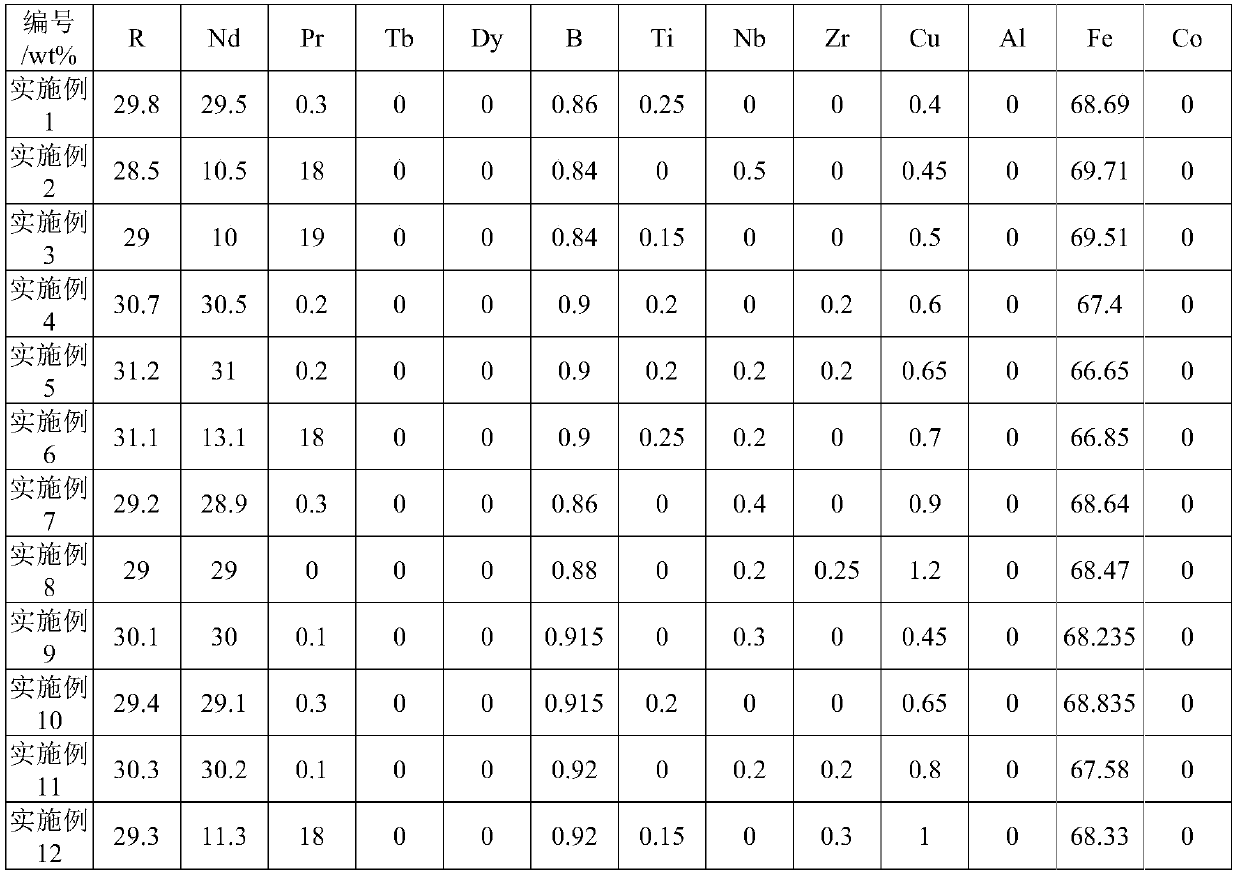

[0081] The raw materials used in the preparation of the R-T-B series permanent magnet material in this embodiment are shown in Table 1. The preparation process is as follows:

[0082] (1) Smelting: According to the formula shown in Table 1, take the prepared raw materials and put them in a crucible made of alumina, and carry out in a high-frequency vacuum induction melting furnace at a temperature of 1500℃ under the condition of a vacuum of less than 0.02Pa Vacuum melting.

[0083] (2) Casting: Ar gas is introduced into the smelting furnace after vacuum smelting to make the pressure reach 55,000 Pa, and then the casting is carried out. The molten liquid is passed through a copper roller with a rotation speed of 29 rpm to obtain a rapid solidification thickness of 0.12-0.35 mm. For alloy flakes, during the casting process, the copper roller needs to be fed with chilled water, and its inlet temperature is ≤25℃; 2 ℃ / sec-10 4 The cooling rate of °C / sec obtains a quenched alloy.

[0084]...

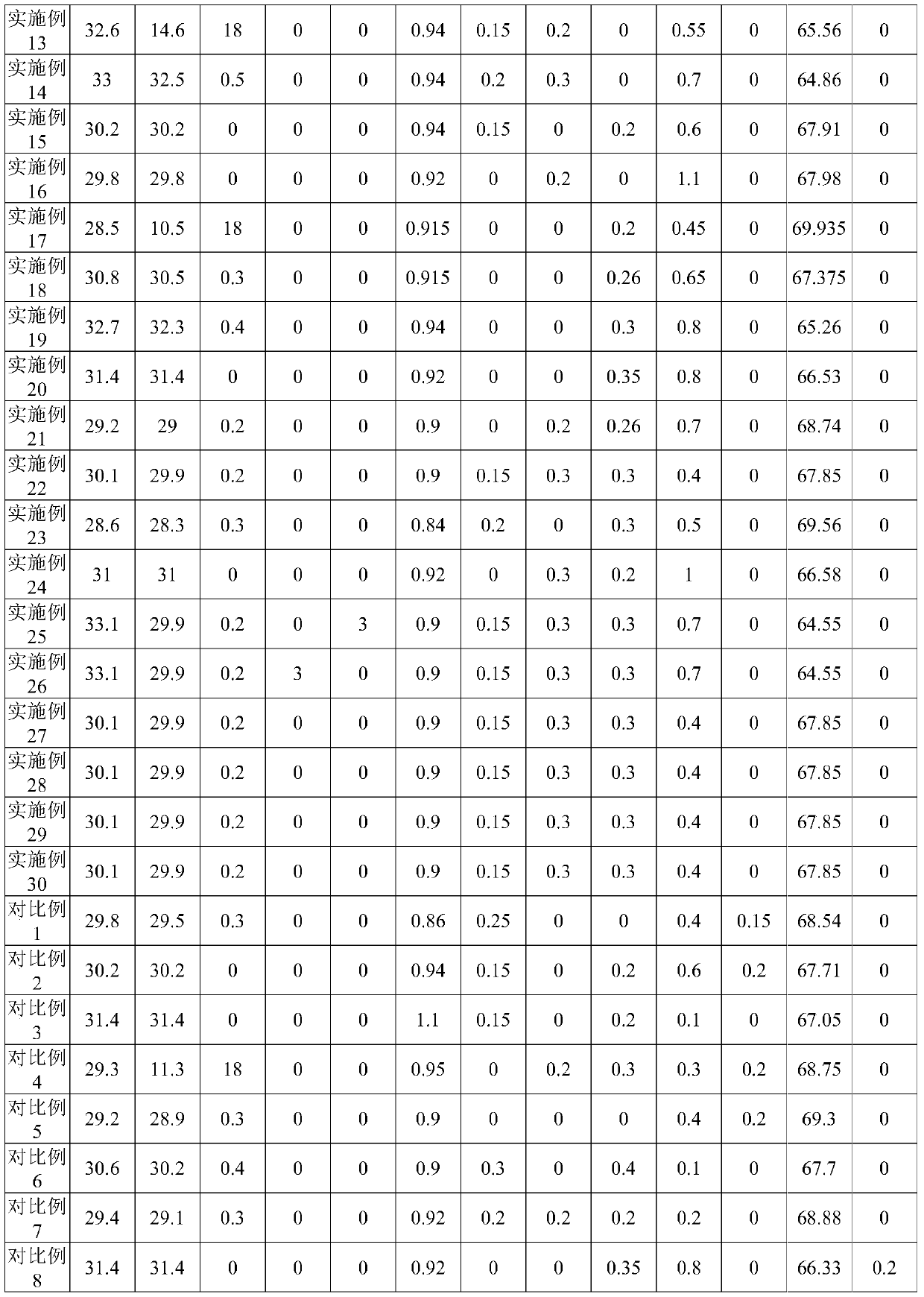

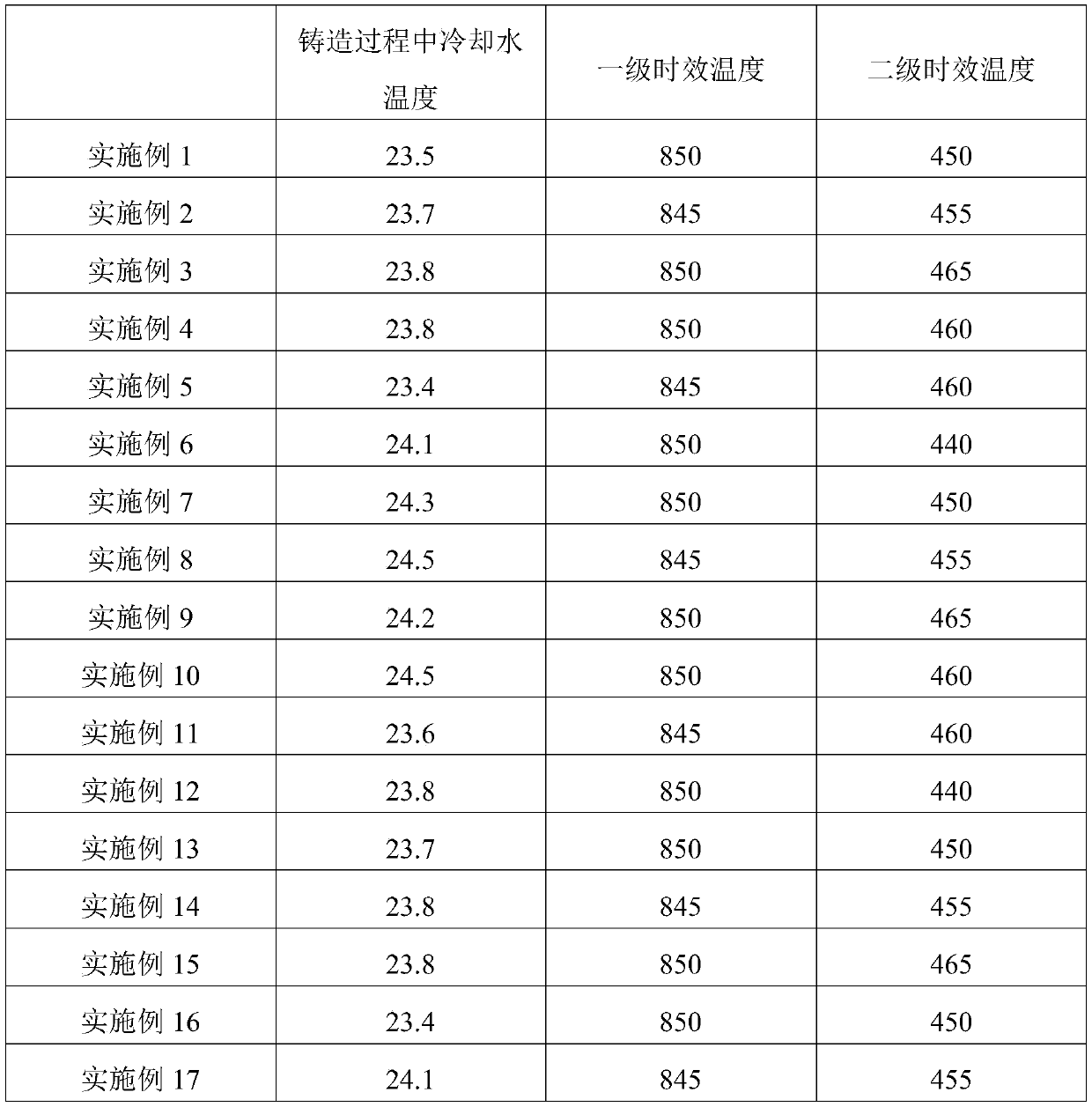

Embodiment 2~26、 comparative example 1~11

[0101] The raw materials were prepared according to the formula shown in Table 1, and except for the conditions shown in Table 2, the other process conditions were the same as those in Example 1, and the R-T-B series permanent magnetic material was prepared.

Embodiment 27~30

[0103] The raw materials of Examples 27-30 are the same as those of Example 22, except for the conditions shown in Table 2, the other process conditions are the same as those of Example 22, to obtain R-T-B series sintered magnets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com