Manufacturing method for Li-B base air suction material

A technology of getter material and getter, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of difficulty in preparing lithium-boron alloy, difficulty in preparing lithium-boron alloy getter sheet, etc., so as to avoid spontaneous combustion phenomenon , The effect of solving processing difficulties and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1. Use metal lithium ingots, fine boron powder, carbon powder, boron carbide powder, and magnesium powder according to the ingredients of 42Li-45B-12C-1Mg;

[0055] 2. Put the ingredients into an argon-protected resistance heating furnace and heat to 370°C, keep warm and stir for 1 hour, so that the powder is completely immersed in it; then cool to room temperature; when heating, control the heating rate to 2°C / min;

[0056] 3. The cooled ingot is billeted and cold-rolled at room temperature in an air with a relative humidity of less than 2% to form a 1×50 (mm) strip, which is stamped into a pre-alloyed disc with a diameter of 10 mm;

[0057] 4. Put the pre-alloyed wafer into an argon-protected resistance furnace and heat it to 700°C for 15 minutes. After cooling to room temperature, take it out and put it in the air with a relative humidity of less than 2% for 0.5 hours to obtain a surface-passivated getter piece. ;

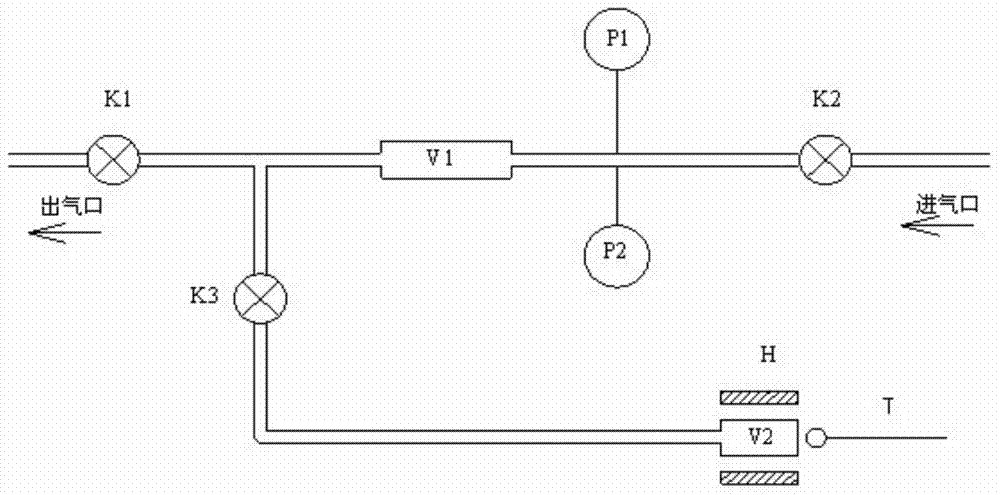

[0058] 5. Both the pre-alloyed sheet and the surfa...

Embodiment 2

[0061] 1. Use metal lithium ingots, fine boron powder, carbon powder, boron carbide powder, and magnesium powder according to the ingredients of 44Li-43.6B-12C-1Mg;

[0062] 2. Put the ingredients into an argon-protected resistance heating furnace and heat to 360°C, keep warm and stir for 2 hours, so that the powder is completely immersed in it; then cool to room temperature; when heating, control the heating rate to 4°C / min;

[0063] 3. The cooled ingot is billeted and cold-rolled in an air with a relative humidity of less than 2% to become a 1×50 (mm) strip, which is stamped into a pre-alloyed disc with a diameter of 10 mm;

[0064] 4. Put the pre-alloyed wafer into an argon-protected resistance furnace and heat it to 600°C for 30 minutes. After cooling to room temperature, take it out and put it in the air with a relative humidity of less than 2% for 3 hours to obtain a surface-passivated getter piece. ;

[0065] 5. Both the pre-alloyed sheet and the surface-passivated suc...

Embodiment 3

[0068] 1. Use metal lithium ingots, fine boron powder, carbon powder, boron carbide powder, magnesium powder, and aluminum powder according to the ingredients of 44Li-43.6B-12C-0.5Mg-0.5Al;

[0069]2. Put the ingredients into an argon-protected resistance heating furnace and heat to 355°C, keep warm and stir for 3 hours, so that the powder is completely immersed in it; then cool to room temperature; when heating, control the heating rate to 5°C / min;

[0070] 3. The cooled ingot is billeted and cold-rolled in an air with a relative humidity of less than 2% to become a 1×50 (mm) strip, which is stamped into a pre-alloyed disc with a diameter of 10 mm;

[0071] 4. Put the pre-alloyed wafer into an argon-protected resistance furnace and heat it to 700°C for 5 minutes, cool it, take it out at room temperature and in air with a relative humidity less than 2%, and place it for 4 hours. Become a surface passivated getter piece.

[0072] 5. Both the pre-alloyed sheet and the surface-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com