Ultra-supercritical thermal power generating unit steel excellent in steam corrosion oxidization resistance and high-temperature endurance property and preparing method thereof

An ultra-supercritical, thermal power unit technology, applied in the field of heat-resistant steel, can solve problems such as damage to steam turbine blades, reduced power generation efficiency, etc., and achieve high-temperature stability assurance, good industrialized manufacturability, and good room temperature mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

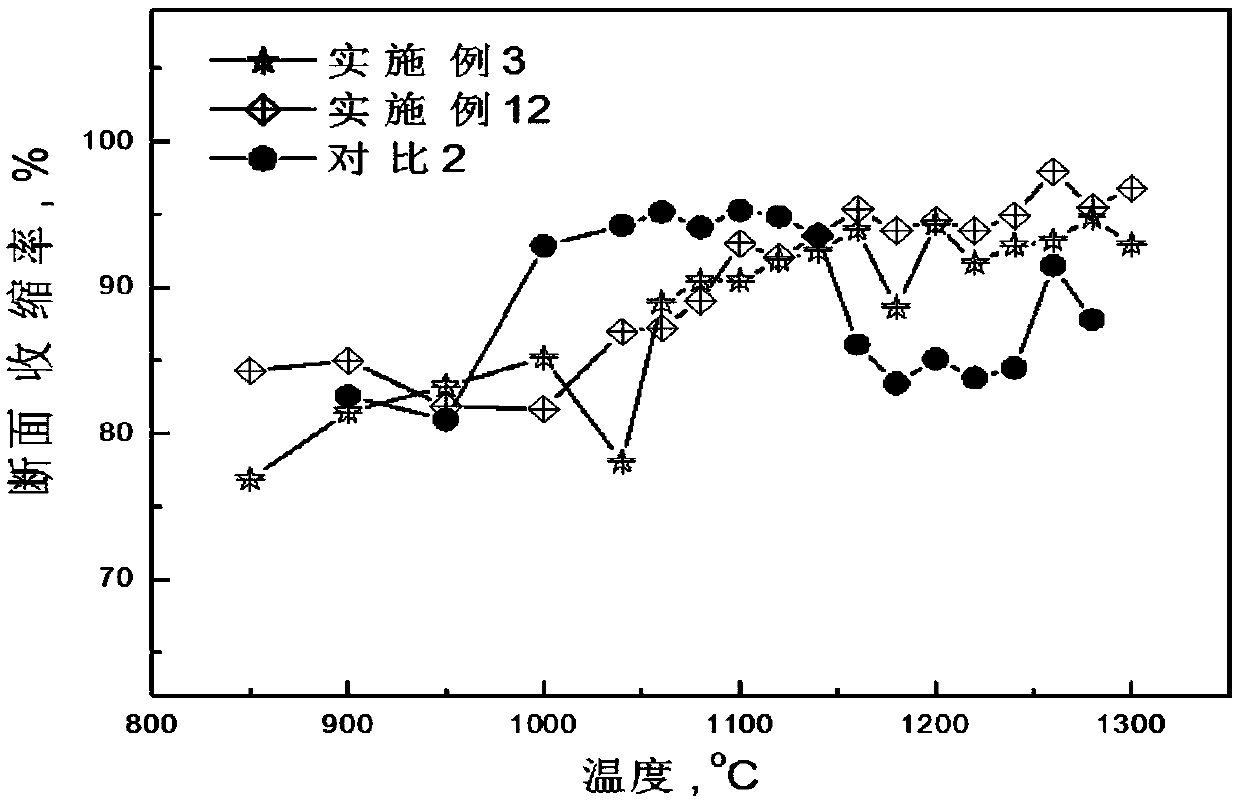

Examples

Embodiment 1

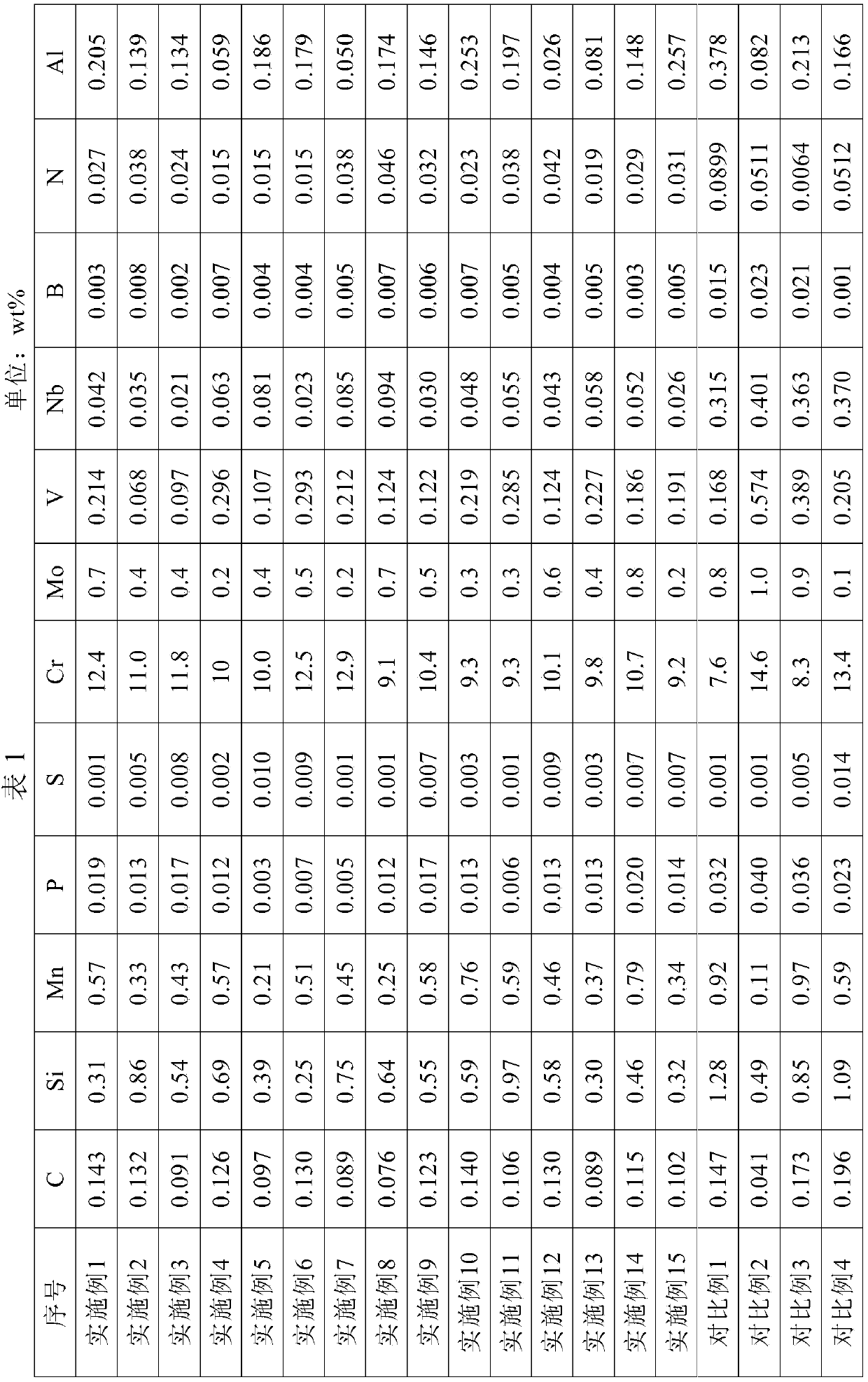

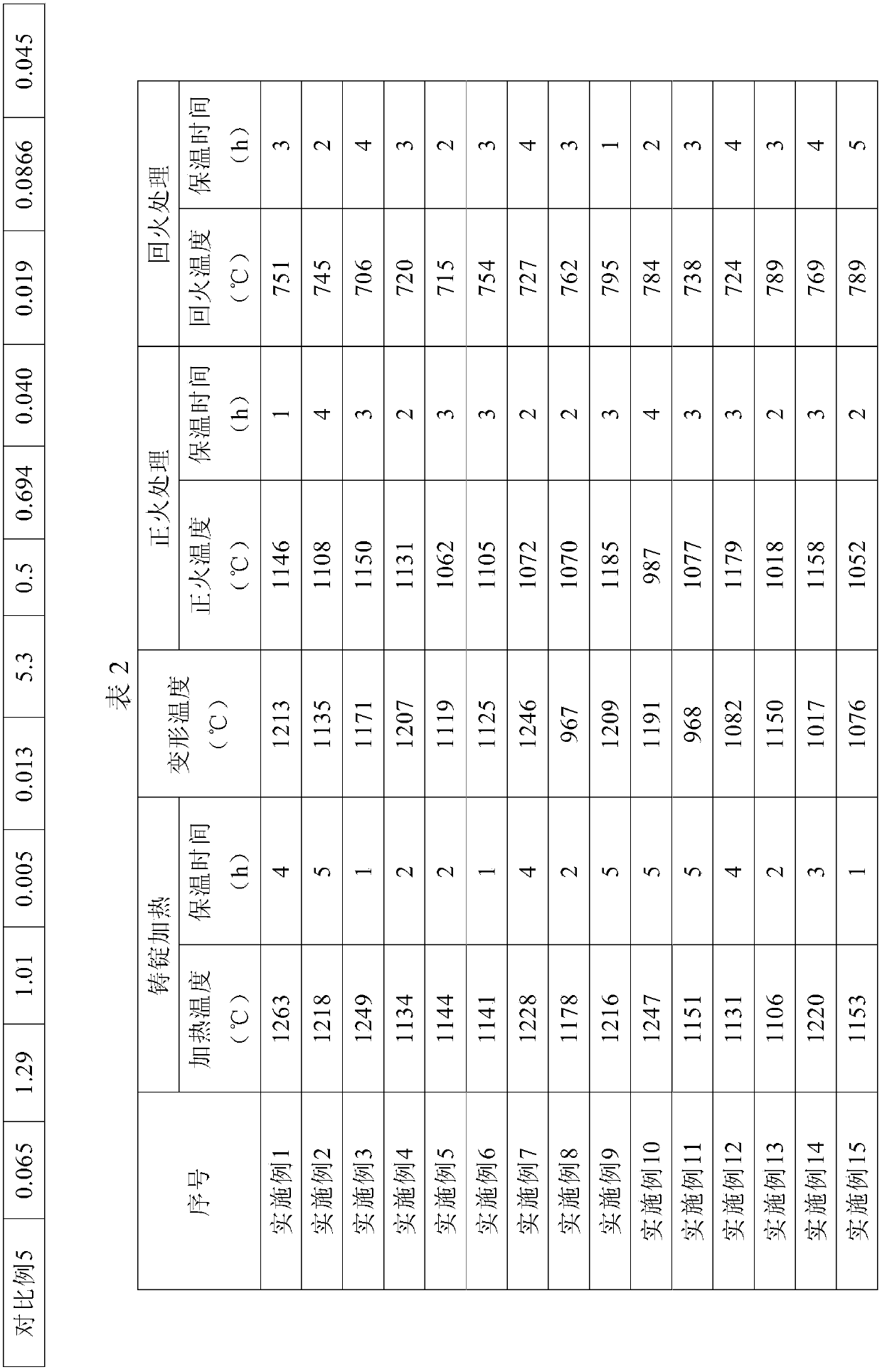

[0045] Use a vacuum induction furnace to smelt 50-500Kg steel ingots with the chemical composition shown in Table 1. After these steel ingots are billeted, they are heated to 1263 ° C, kept for 4 hours, and the deformation temperature is 1213 ° C. rolling plate. Next, the hot-rolled sheet was normalized and kept at 1146° C. for 1 hour, air-cooled to room temperature, then kept at 751° C. for 3 hours, and air-cooled to room temperature. The normal temperature mechanics, long-term failure and durable strength were taken from the above heat-treated steel plate, and the measured properties are shown in Table 3.

[0046] The water vapor oxidation test procedure is as follows: Preparation of H 2 O-air mixed gas: compressed air is used as the carrier gas to form 18% H through a water bath at a certain temperature 2 O--air mixture. The gas path between the water bath and the high temperature furnace is insulated (the temperature is higher than the temperature of the water bath) to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com