Preparation method of high-temperature methanation catalyst applicable to preparation of methane by reacting CO and CO2 with hydrogen

A methanation catalyst and methane production technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of large water consumption, air pollution, magnesium The problems of high energy consumption of aluminum spinel can reduce energy consumption and cost, ensure high temperature stability, and ensure low temperature and high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

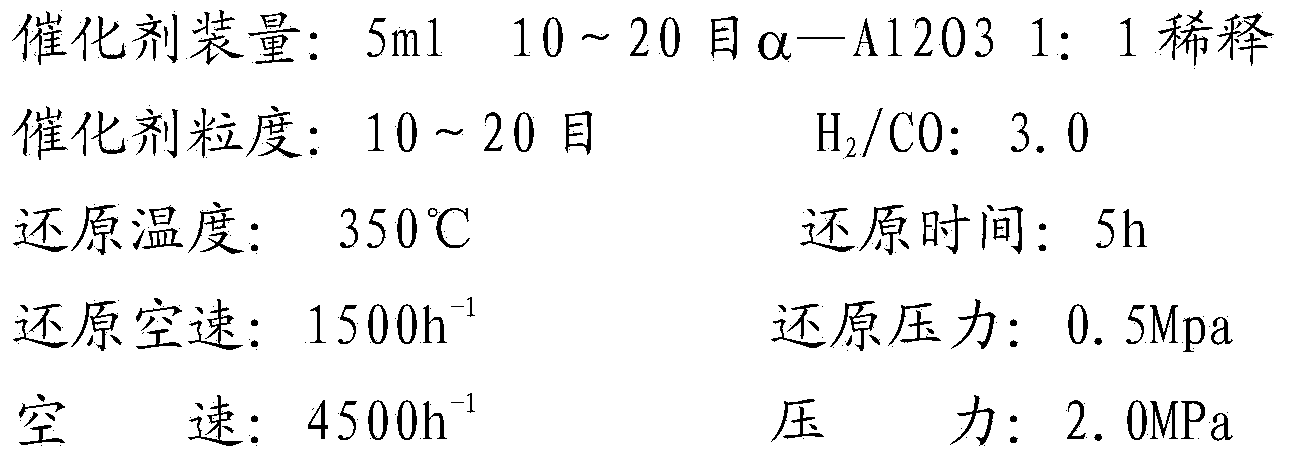

Method used

Image

Examples

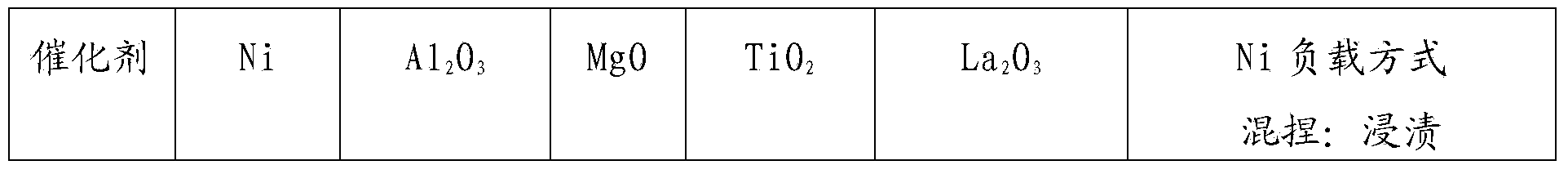

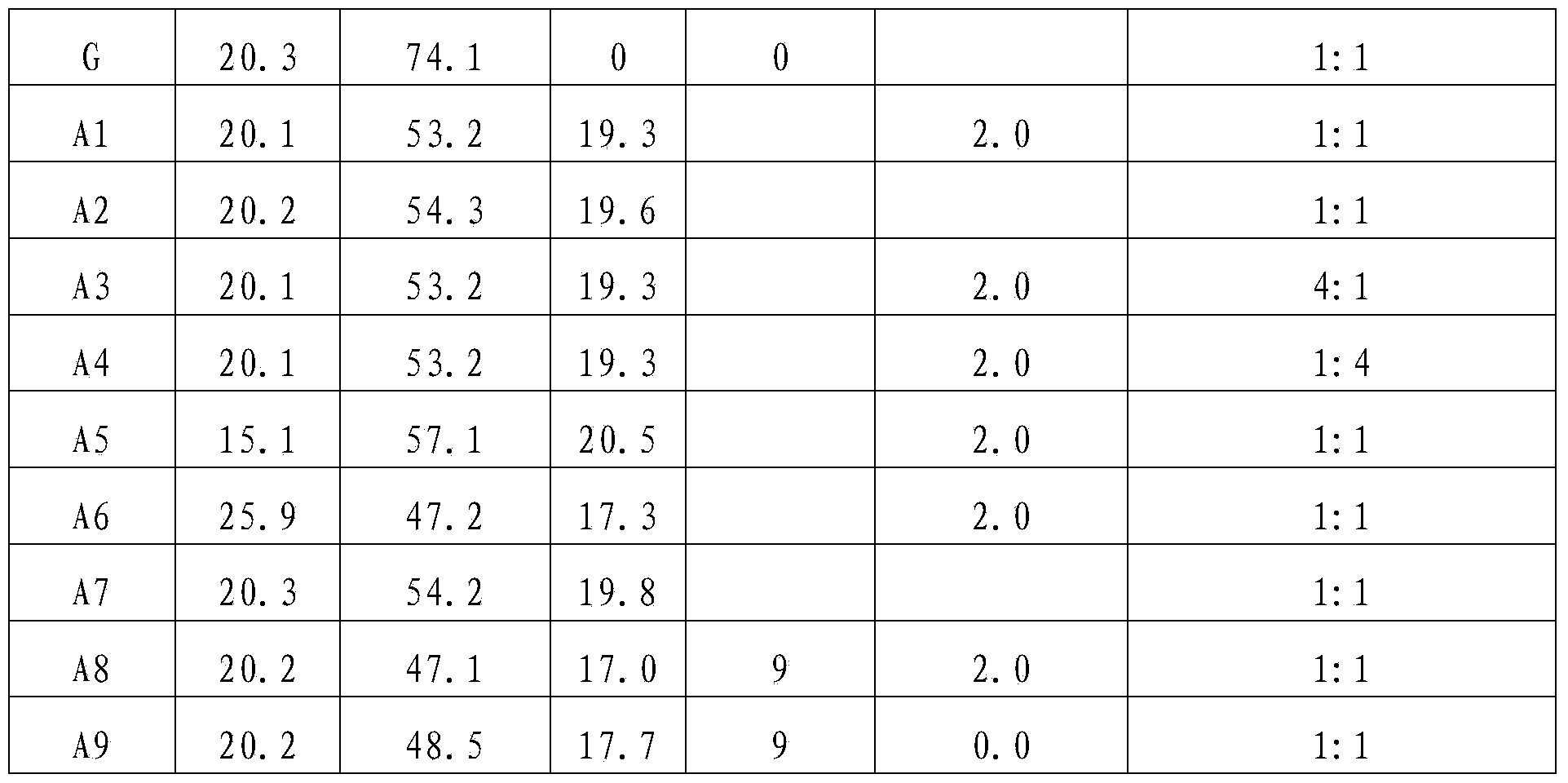

Embodiment 1

[0043] A. Weigh Al 2 o 3 63%Al 2 o 3 -nH 2 O1800g, light MgO445g, mix the two evenly; add 100ml of aqueous solution containing 10.63g of lanthanum nitrate; add 33.7g of peptizer citric acid and 1000ml of water, knead evenly, then dry at 120°C for 3~5h, and roast at 580°C for 2~3h, Cool down to room temperature and pulverize to 180 mesh or more to obtain mixed material III;

[0044] B. At room temperature, weigh 1000g of nickel nitrate, dissolve it in 1000ml of water, add it to the mixture III in step A and mix evenly; then dry at 120°C for 3-5h, roast at 580°C for 2-3h, cool down to room temperature and pulverize To 180 mesh or more to obtain dry powder material IV;

[0045] In the dry powder material IV, add 3% of Tianqing powder (based on the mass of the dry powder material), 3% of the peptizer citric acid (based on the mass of the dry powder material), and 900g of water, knead evenly, and then carry out molding, Dry at 120°C for 3 hours, and bake at 720°C for 3 hours ...

Embodiment 2

[0049] A. Weigh Al 2 o 3 63%Al 2 o 3 -nH 2 O1805g, light MgO446g, mix the two evenly; add peptizer citric acid 33.7g and 1000ml water and knead evenly, then dry at 120°C for 3-5h, roast at 580°C for 2-3h, cool to room temperature and pulverize to above 180 mesh to obtain Mixture III;

[0050] B. At room temperature, weigh 1000g of nickel nitrate, dissolve it in 1000ml of water, add it to the mixture III in step A and mix evenly; then dry at 120°C for 3-5h, roast at 580°C for 2-3h, cool down to room temperature and pulverize To 180 mesh or more to obtain dry powder material IV;

[0051] In the dry powder material IV, add 3% of Tianqing powder (based on the mass of the dry powder material), 3% of the peptizer citric acid (based on the mass of the dry powder material), and 900g of water, knead evenly, and then carry out molding, Dry at 120°C for 3 hours, and bake at 720°C for 3 hours to obtain dry powder material Ⅴ. Cool down to room temperature to measure its water absorp...

Embodiment 3

[0055] The preparation process, proportion and composition content are the same as in Example 1, and the ratio of kneading Ni and impregnating Ni is adjusted to 4:1 to prepare catalyst A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com