Oil well cement high temperature resistance suspending agent

A technology of oil well cement and high temperature resistance, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor stability of cement slurry, etc., and achieve the effects of maintaining high temperature stability, improving stability, and strong high temperature suspension ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 65 parts of 2-acrylamido-2-methylpropanesulfonic acid, 25 parts of acrylamide, and 5 parts of N,N-dimethylacrylamide in a beaker, stir to dissolve, and then add sodium hydroxide to adjust the pH of the solution= 7. Pour it into a cleaned three-necked bottle, add 5 parts of monomers containing hydrophobic groups, turn on the stirring and heating device, and fill it with nitrogen. When the system temperature reached 50°C, 0.6 part of initiator was added to initiate the polymerization reaction, and the reaction was stopped after 5 hours of constant temperature reaction. The synthetic product was washed with ethanol for purification, dried, and ground to obtain a solid powder. The drilling bentonite and the hydrophobically associated water-soluble polymer solid powder were mixed uniformly at a mass ratio of 5:1 to prepare a high-temperature-resistant suspension concentrate, which was marked as 1# sample.

Embodiment 2

[0018] Weigh 55 parts of 2-acrylamido-2-methylpropanesulfonic acid, 30 parts of acrylamide, and 5 parts of N,N-dimethylacrylamide, stir and dissolve in a beaker, then add sodium hydroxide to adjust the pH of the solution to 7 , poured into a cleaned three-necked bottle, then added 10 parts of monomers containing hydrophobic groups, turned on the stirring and heating device, and filled with nitrogen. When the system temperature reached 50°C, 0.6 part of initiator was added to initiate the polymerization reaction, and the reaction was stopped after 5 hours of constant temperature reaction. The synthetic product was washed with ethanol for purification, dried, and ground to obtain a solid powder. The drilling bentonite and the hydrophobically associated water-soluble polymer solid powder were mixed uniformly at a mass ratio of 5:1 to prepare a high-temperature-resistant suspension concentrate, which was marked as 2# sample.

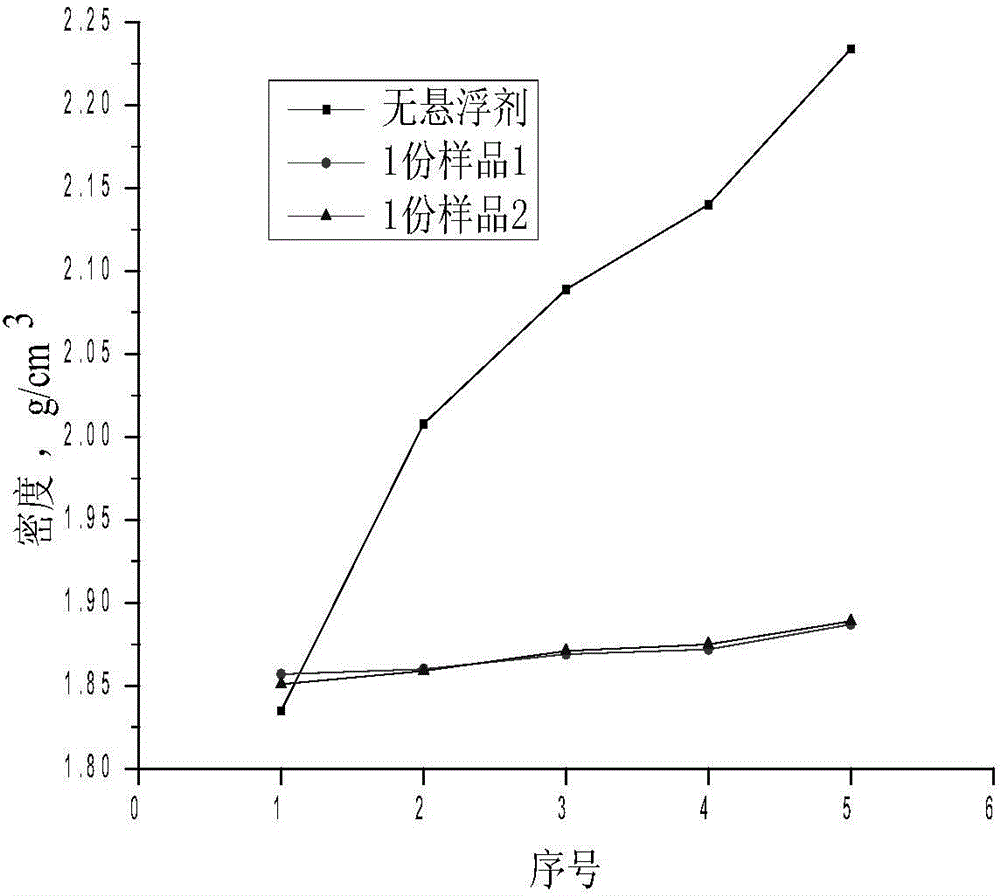

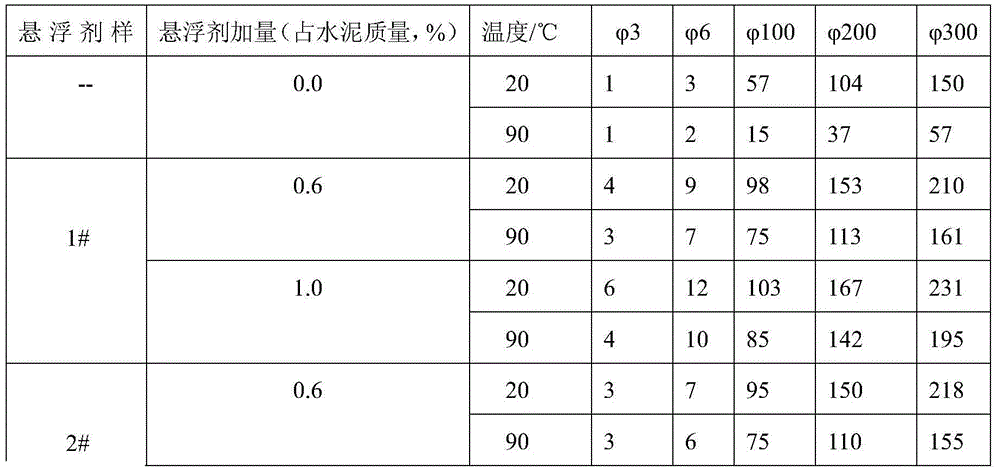

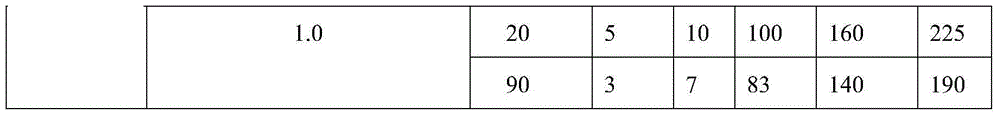

[0019] Performance Evaluation of Prepared High Tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com